Feb . 18, 2025 10:02 Back to list

pvc coated wire mesh panels

Trust and credibility are significantly bolstered by the panels' compliance with industry standards. Many manufacturers of PVC coated wire mesh panels adhere to stringent quality controls. This ensures that every panel not only meets but often exceeds expectations regarding safety and performance. This level of quality assurance is critical for buyers seeking long-term investments, adding to the authority and trustworthiness of PVC coated wire mesh as a market leader. For those who have firsthand experience installing these panels, the consensus is clear their cost-effectiveness cannot be overstated. Initially, some might assume that their durability and customization options equate to a higher price point. However, when considering the reduced need for maintenance, repairs, or replacements, professionals quickly recognize the substantial savings offered over time. This economic benefit is amplified when factoring in the panels’ energy-efficient production process, another appealing feature for environmentally conscious consumers. Considering all the above factors, it is evident why PVC coated wire mesh panels are revered in multiple sectors. They cater to a wide array of needs without compromising on quality or appearance. As industries increasingly prioritize products that deliver both performance and sustainability, these panels perfectly embody those ideals, strengthening their standing as a go-to solution. In essence, PVC coated wire mesh panels offer unmatched expertise, experience, and trustworthiness across diverse applications, making them a vital component in modern construction and design. Their robust performance, coupled with aesthetic flexibility and environmental benefits, ensures their relevance and popularity for years to come, solidifying their place as a leader in the realm of mesh solutions.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

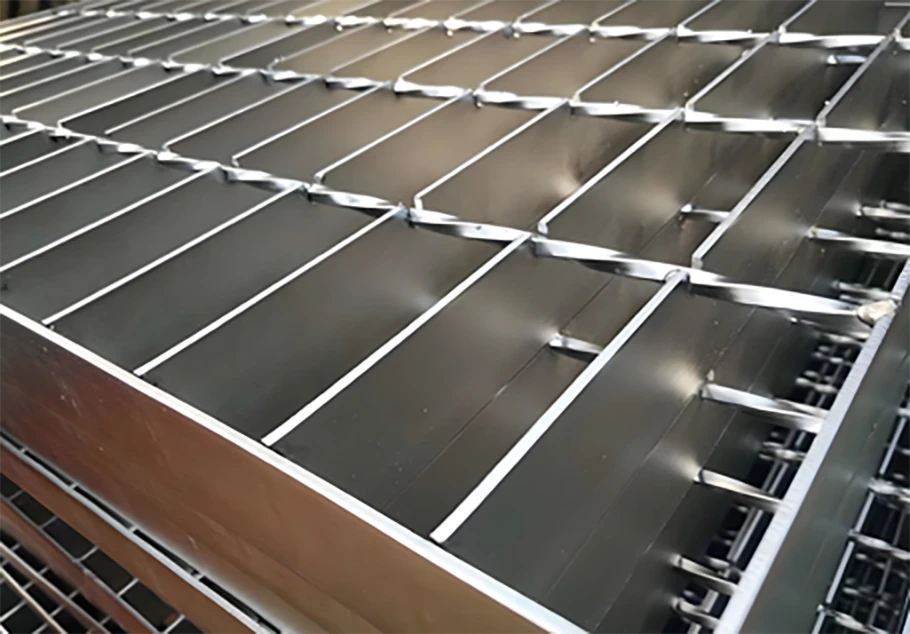

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA