Feb . 19, 2025 10:28 Back to list

pvc coated welded wire mesh panels

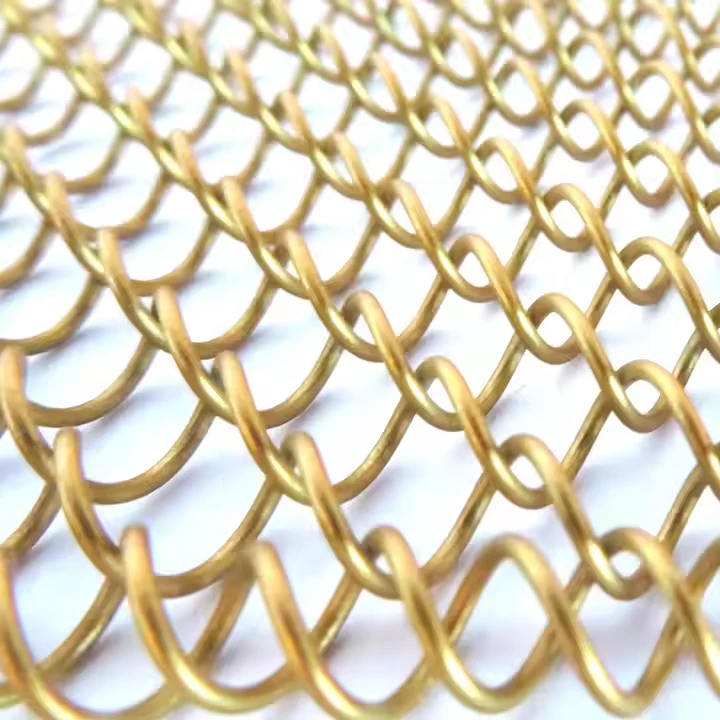

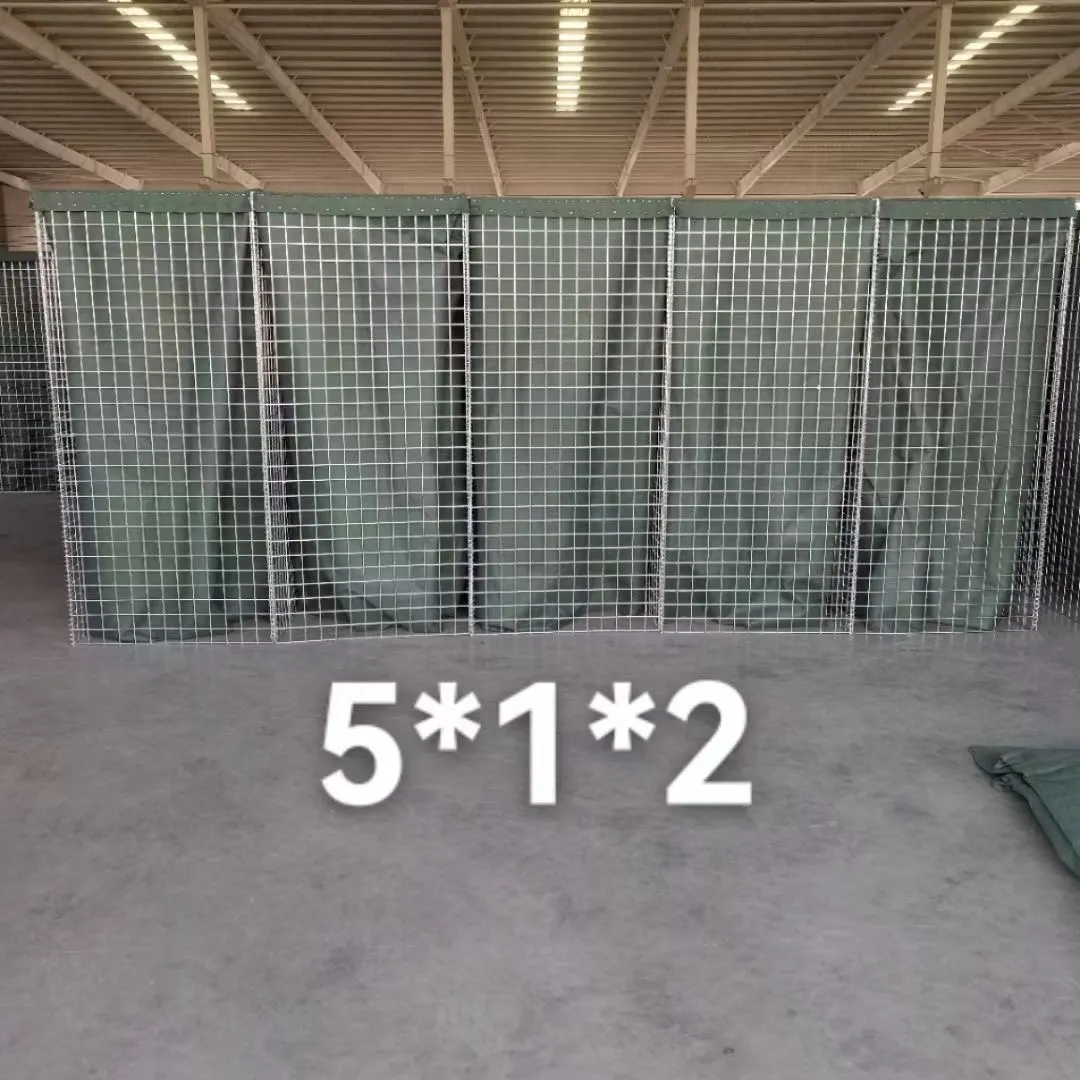

Trustworthiness is further reinforced by the panels' performance track record. Industrial users, from livestock operators to perimeter security solutions providers, have documented the panels' effectiveness in protecting assets without compromising on environmental compatibility. PVC-coated welded wire mesh panels are recyclable, making them a sustainable choice that supports eco-friendly initiatives without sacrificing quality or durability. The versatility of these panels extends beyond just security and aesthetics. In environments where safety is a priority, such as schools, sports complexes, and playgrounds, these mesh panels are employed to create barriers that are both safe and durable. The smooth finish of PVC coating minimizes injury risks, ensuring they are child-friendly and suitable for public use. Moreover, these panels are customizable to suit the specific needs of various projects. Options in mesh size, wire diameter, panel height, and color provide businesses with the flexibility to tailor solutions precisely to their requirements. This customization capability is particularly valuable in branding and thematic projects, where corporate colors or design motifs may need to be integrated. As industries advance and the demand for cost-effective, long-lasting solutions grows, PVC-coated welded wire mesh panels are at the forefront of innovation. Their strategic advantages — from superior durability and environmental resistance to ease of installation and customization — position them as a key player in the future of fencing solutions. Businesses prioritizing security, durability, and aesthetics are increasingly turning to these panels not merely as a product choice, but as a strategic investment in reliability and quality.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA