Feb . 14, 2025 15:28 Back to list

pvc arch bead

Consumer trust is further reinforced by years of consistent performance. PVC arch beads are favored for their resistance to moisture, which is fundamentally crucial in environments prone to dampness. This resistance extends the lifespan of the beads and, by extension, the structural harmony of the building elements they protect. Builders frequently highlight PVC’s non-reactive nature that ensures longevity without corrosion – a point underscored during projects involving coastal constructions, where salt air can accelerate material degradation. Moreover, PVC arch beads contribute to efficiency in construction, reducing labor intensity and error rates. Their design promotes swift alignment and secure attachment to surfaces, streamlining processes in both residential and commercial projects. The typical lifespan of these products aligns with general construction service life expectations, supporting sustainable building practices. In conclusion, PVC arch beads represent a sophisticated blend of practical application, expert validation, and trusted results. They fill a niche in the construction industry that demands precision, durability, and adaptability. With continual improvements and unwavering support from both the manufacturing sector and on-the-ground professionals, PVC arch beads remain an indispensable asset for those seeking modern, reliable, and aesthetically admirable solutions in architectural detailing. As the construction landscape evolves, these beads set a benchmark for what professionalism and expertise should translate into within the building crafts.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

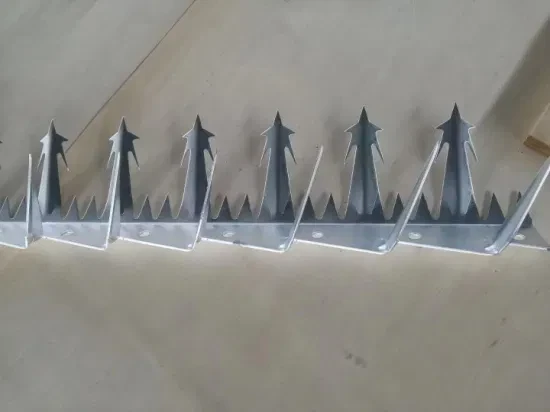

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA