Jan . 10, 2025 08:48 Back to list

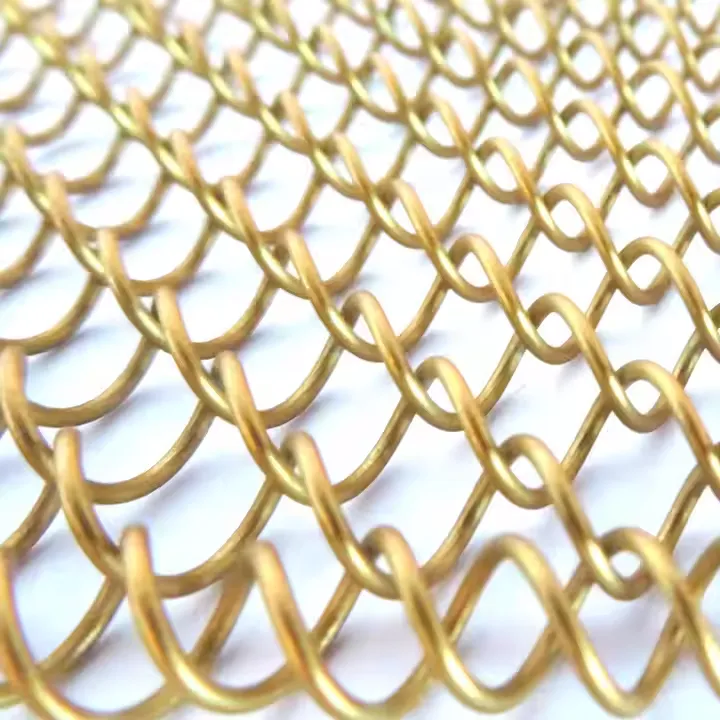

purpose of wire gauze

The evolution of wire gauze technologies reflects ongoing advancements in material science and engineering. Modern wire gauze is crafted with precision to enhance its heat conductivity and filtration capabilities. Recent innovations have seen the integration of ceramic fibers, which significantly boost its heat resistance while being lightweight. These improvements have expanded the possibilities of wire gauze applications, making it a staple in cutting-edge research labs and high-tech manufacturing processes. Authoritativeness in the domain of wire gauze utilization and innovation comes from countless studies and expert reviews. Scientific journals meticulously document its use and efficacy, while industry standards dictate specific grades and compositions suitable for various applications. This treasure trove of peer-reviewed evidence fortifies the standing of wire gauze as a critical component in ensuring both safety and success in complex scientific endeavors. Trust in wire gauze stems not only from its widespread use and historical significance but also from the rigorous quality controls and certifications it undergoes. Whether through ISO standards or ASTM specifications, wire gauze products are subject to stringent testing to confirm their reliability and safety. This commitment to quality assurance reinforces the confidence professionals place in wire gauze, ensuring it remains a trusted tool in their arsenal. In summary, the purpose of wire gauze extends far beyond its basic appearance. It is a pillar of safety, precision, and efficiency in various fields. Through continuous innovation and unwavering adherence to quality standards, wire gauze maintains its position as an indispensable resource, its value recognized and esteemed by those who seek to harness its capabilities for optimal results.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

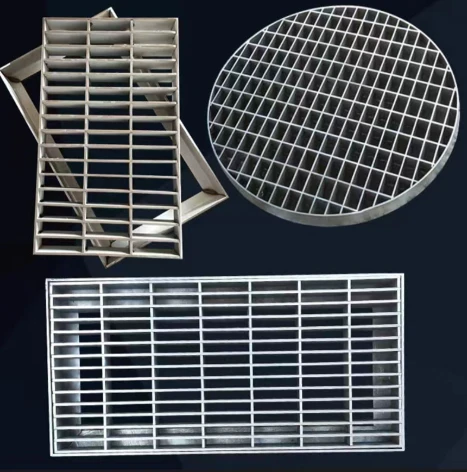

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA