Feb . 13, 2025 11:53 Back to list

plastic angle beads for rendering

From an authority perspective, leading construction professionals endorse plastic angle beads for their superior performance in both residential and commercial applications. Industry standards dictate the use of corrosion-resistant materials in construction. Plastic angle beads naturally align with these standards, making them a recommended choice by regulatory bodies and construction experts alike. Trustworthiness is an attribute earned through consistent product performance and reliability, qualities that plastic angle beads for rendering consistently demonstrate. Contractors globally have reported fewer post-installation issues when using plastic beads compared to their metal counterparts. This not only increases client satisfaction but also reduces maintenance costs and time spent on repairs. To illustrate, consider a case study where a large commercial office building underwent external rendering. By integrating plastic angle beads, the builders achieved an immaculate finish that remained intact beyond the projected lifespan of standard materials. This not only reinforced the building’s structural integrity but also upheld the designer’s vision without compromise. The successful implementation of plastic angle beads enhanced the building's overall value and contributed to a more sustainable construction process. In conclusion, plastic angle beads for rendering are an indispensable tool in the modern construction toolkit. Their design innovation and proven reliability address both aesthetic and functional needs in rendering projects. Choosing plastic angle beads ensures durable, high-quality outcomes, aligning with industry best practices and meeting contemporary building standards. With these beads, both residential and commercial render applications benefit from enhanced structural integrity and visual appeal, ultimately leading to long-term client satisfaction and project success.

Latest News

-

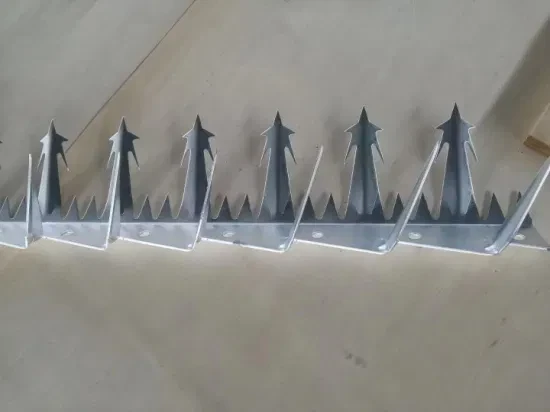

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA