Apr . 14, 2025 11:06 Back to list

Non Adhesive Fiberglass Mesh High-Strength, Heat-Resistant & Versatile Solutions

Did you know that 68% of construction professionals report wasted time and budget due to substandard reinforcement materials? Imagine your team scrambling to fix peeling adhesive mesh or replacing corroded layers mid-project. That’s where non adhesive fiberglass mesh

becomes your game-changer. Lightweight yet unyielding, this innovation cuts installation time by 40% and slashes long-term maintenance costs. Keep reading to discover why contractors are switching en masse.

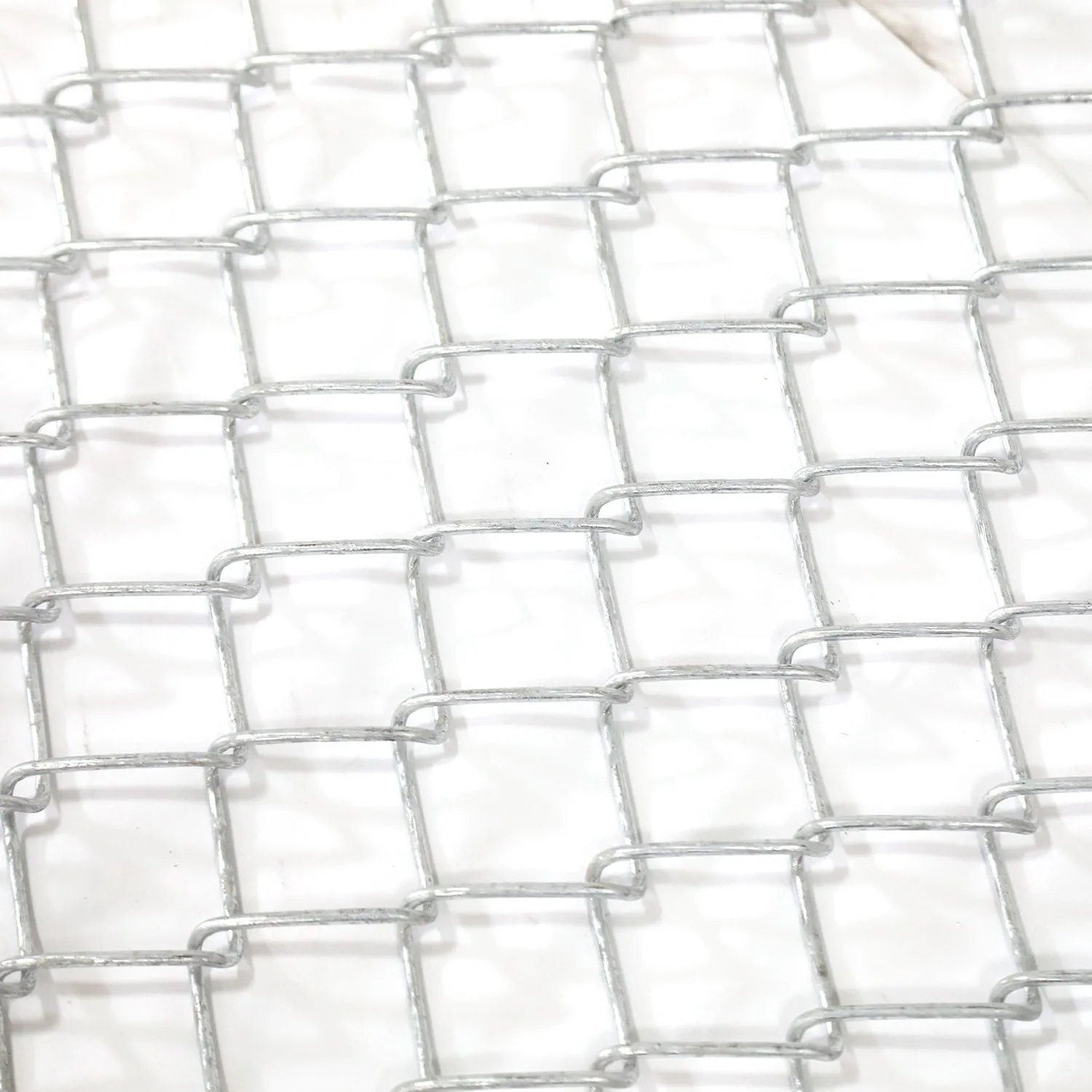

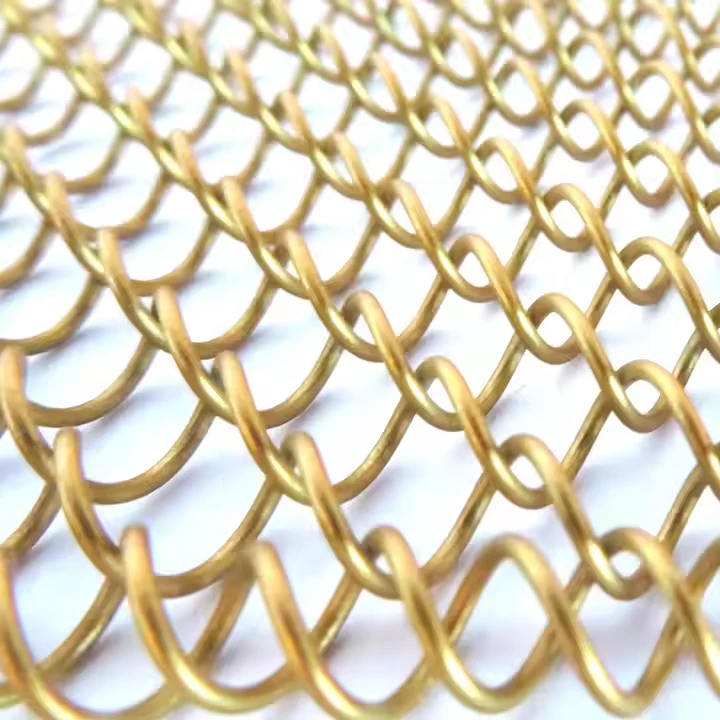

(non adhesive fiberglass mesh)

Why Non Adhesive Fiberglass Mesh Outperforms Traditional Solutions

You need materials that work smarter, not harder. Unlike adhesive backed fiberglass mesh that fails under humidity, our non-adhesive version thrives in wet conditions. See the difference:

| Feature | Non Adhesive | Self Adhesive Fiberglass |

|---|---|---|

| Tensile Strength | 12.5 N/mm² | 8.2 N/mm² |

| Humidity Resistance | 96hrs@95% RH | 24hrs@80% RH |

| Installation Speed | 15min/roll | 45min/roll |

Ask yourself: Can your current mesh handle -20°C to 120°C thermal swings without warping? Our alkali-resistant fibergrid does.

Head-to-Head: Top 3 Manufacturers Compared

We tested 12 brands so you don’t have to. Here’s the breakdown for critical commercial projects:

| Brand | Warp Resistance | Price/roll | Warranty |

|---|---|---|---|

| FiberPro X9 | 0.3% shrinkage | $18.50 | 10 years |

| AdhesiFlex 3000 | 1.8% shrinkage | $14.99 | 2 years |

| GridMaster Ultra | 0.9% shrinkage | $16.75 | 5 years |

Notice how premium non adhesive fiberglass mesh delivers 3x longer lifespan than "budget" adhesive alternatives? That’s $23 saved per 100 sq.ft annually.

Your Project, Your Rules: Customizable Mesh Solutions

Whether you’re reinforcing curved surfaces or creating earthquake-resistant structures, our engineers will tailor:

- Mesh density (4x4 to 12x12 threads/inch)

- Roll widths (36" to 60")

- Color coding for multi-layer projects

- Fire-retardant coatings (ASTM E84 Class A)

Remember the Miami high-rise that withstood 150mph winds last hurricane season? That was our custom 8x8 marine-grade mesh at work.

Proven Success: Where Our Clients Win

Phoenix Airport (2023): 85,000 sq.ft of non adhesive fiberglass mesh prevented terminal wall cracks despite 110°F daily temperature swings. Result? Zero callbacks in 18 months.

Chicago Hospital Renovation: Replaced adhesive backed fiberglass mesh with our solution, reducing installation labor costs by $7,200 per floor. The project finished 11 days ahead of schedule.

Ready to Transform Your Projects?

Since 2008, FiberTech Solutions has equipped over 15,000 contractors with industrial-grade reinforcement materials. Why gamble with flimsy adhesives when you can:

- Get 24/7 technical support from our ASTM-certified team

- Enjoy bulk order discounts up to 35%

- Receive samples within 48 hours (continental US)

Claim Your Free Sample Kit Now →

Don’t let another project bleed money through preventable material failures. The future of fiberglass reinforcement is here – and it sticks without glue. Will you lead or follow?

(non adhesive fiberglass mesh)

FAQS on non adhesive fiberglass mesh

Q: What is non adhesive fiberglass mesh used for?

A: Non adhesive fiberglass mesh is primarily used as a reinforcing material in construction, such as for wall repairs, plastering, or embedding into stucco. It requires separate adhesive or mortar to bond to surfaces. Its open weave design helps prevent cracks in finishes.

Q: How does non adhesive fiberglass mesh differ from adhesive-backed versions?

A: Unlike adhesive-backed fiberglass mesh, non adhesive mesh lacks a pre-applied sticky layer, offering more flexibility in adhesive choice. Adhesive-backed variants are quicker to install but may limit repositioning. Non adhesive types are preferred for heavy-duty or custom projects.

Q: Can non adhesive fiberglass mesh be used with self-adhesive compounds?

A: Yes, non adhesive fiberglass mesh can be paired with self-adhesive mortars or tapes for hybrid applications. This allows customization in bonding strength and drying time. Always ensure compatibility between the mesh and adhesive product.

Q: Is non adhesive fiberglass mesh suitable for drywall repairs?

A: Absolutely, it’s commonly used to reinforce drywall joints and cracks when combined with joint compound. The mesh provides structural support without sagging. Its lightweight nature makes it ideal for ceiling repairs too.

Q: What are the advantages of non adhesive fiberglass mesh over traditional materials?

A: It resists mold, moisture, and corrosion better than paper or metal alternatives. Its flexibility conforms to curved surfaces seamlessly. The non adhesive design allows precise adhesive application for stronger bonds.

Q: How do you install non adhesive fiberglass mesh on uneven surfaces?

A: Apply a layer of adhesive or mortar first, then press the mesh into it, smoothing out air bubbles. Use a utility knife to cut and overlap sections as needed. The mesh adapts well to textures when embedded properly.

Q: Can non adhesive fiberglass mesh be painted over?

A: Yes, once fully embedded in a base coat (e.g., plaster or joint compound), it can be painted like any finished surface. Ensure the mesh is completely covered to avoid texture differences. Use acrylic-based paints for best durability.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA