Jan . 15, 2025 01:18 Back to list

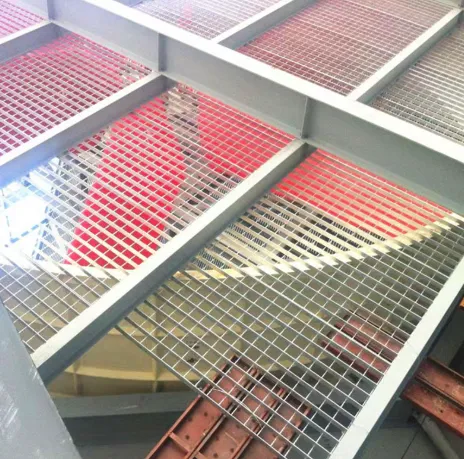

lightweight walkway grating

From a trustworthiness perspective, selection of high-quality lightweight grating is dependent on certification and compliance with industry standards such as ASTM, ANSI, or specific international guidelines. Top manufacturers typically subject their products to rigorous testing, ensuring they meet or exceed the required safety and durability metrics. Considerations such as load capacity, slip resistance, and fire retardancy are crucial in specifying and selecting the right grating for any given application. Furthermore, real-world experience illustrates that deploying lightweight walkway grating helps streamline maintenance efforts. Thanks to their construction, these grates are more resistant to absorption and surface damage, leading to lower maintenance costs over their lifecycle. Customers who have transitioned to lightweight solutions report not only significant reductions in repair overheads but also improvements in safety for personnel utilizing these walkways, reaffirming the dual benefits of this modern solution. In conclusion, the lightweight walkway grating represents a technological advancement that addresses the growing demand for safer, more efficient, and cost-effective grating solutions. As industries continue to evolve, investing in lightweight options ensures not only operational efficiency but also aligns with sustainable practices and long-term structural integrity. Whether for new installations or retrofitting existing structures, choosing lightweight walkway grating proves to be a smart, forward-thinking decision.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA