Jan . 12, 2025 09:49 Back to list

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

Furthermore, the authoritative nature of safety grating is validated by stringent industry standards and certifications. For companies committed to maintaining compliance and prioritizing safety, opting for grating materials that adhere to OSHA standards or similar regulated benchmarks is non-negotiable. It provides peace of mind, knowing that the products being used are tested and certified for their intended applications. Trustworthiness is integral when selecting a safety grating supplier. Partnering with manufacturers who have a proven track record and a portfolio showcasing successful installations is crucial. Personal interactions with seasoned suppliers reveal that their commitment to quality and service can drastically influence the product's effectiveness. One well-reputed supplier I encountered provided not only high-quality grating but also comprehensive installation support, ensuring that the product's safety benefits were fully realized. In conclusion, safety grating is more than just a functional element in infrastructure; it represents a commitment to creating safer work environments. Its integration into facilities doesn't only meet safety requirements but also enhances operational fluidity and reliability. By drawing on industry expertise, understanding specific needs, and partnering with reputable suppliers, businesses can maximize the benefits of safety grating, ultimately leading to a more secure and productive working environment. The knowledge and application of this critical safety tool underscore its importance and continuous relevance in today's industrial landscape.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

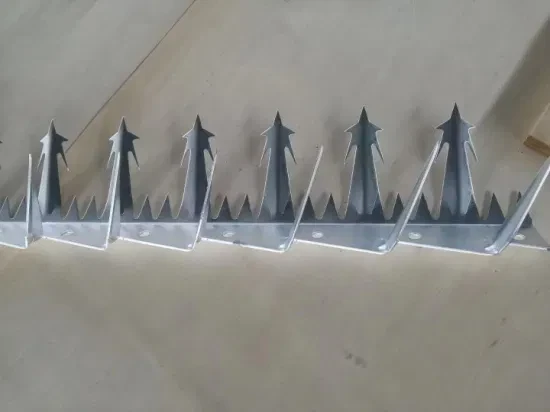

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA