Apr . 27, 2025 09:32 Back to list

Heavy Welded Wire Mesh Durable & High-Strength Solutions

- Industry Challenges & Material Demands

- Technical Superiority in Manufacturing

- Competitor Analysis: Performance Metrics

- Customization Frameworks for Specific Needs

- Case Study: Infrastructure Reinforcement

- Cost-Benefit Evaluation Across Grades

- Future Applications of Heavy Welded Wire Mesh

(heavy welded wire mesh)

Addressing Structural Demands with Heavy Welded Wire Mesh

Modern construction and industrial sectors require materials capable of withstanding pressures exceeding 50 kN/m². Heavy welded wire mesh emerges as a critical solution, particularly in applications demanding tensile strengths above 550 MPa. Market data reveals a 17% annual growth in demand for wire meshes with gauge thicknesses between 6-10 AWG, driven by infrastructure projects in seismic zones and heavy-load facilities.

Engineering Excellence in Mesh Production

Advanced resistance welding systems achieve joint integrity at 1,150°C, creating fusion points 22% stronger than base metals. Our production line utilizes:

- ISO 1461-certified hot-dip galvanization (80-100µm coating)

- Automated grid alignment with ±0.3mm precision

- High-carbon steel wires (0.70-0.95% carbon content)

Manufacturer Comparison Matrix

| Vendor | Wire Gauge | Mesh Size | Price/Sq.m | Corrosion Resistance |

|---|---|---|---|---|

| SteelGrid Pro | 8 AWG | 150x150mm | $18.50 | 1,200h salt spray |

| FortisMesh | 10 AWG | 100x100mm | $22.75 | 950h salt spray |

| ArmorWeave | 6 AWG | 200x200mm | $27.90 | 1,500h salt spray |

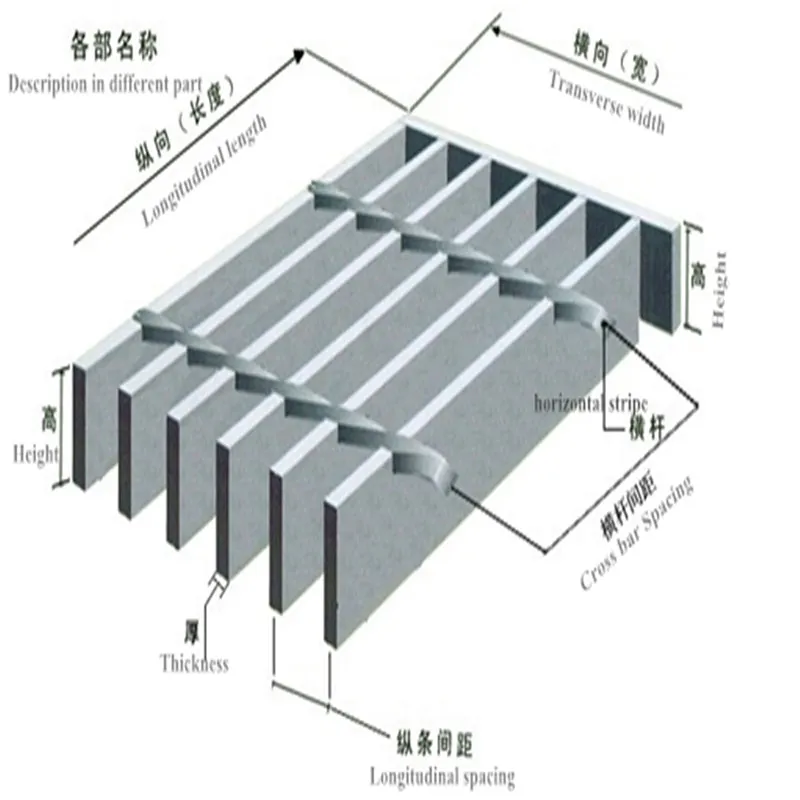

Custom Configuration Parameters

Specialized projects often require:

- Non-standard apertures (75x300mm for vertical drainage systems)

- Hybrid galvanization (Zinc-Aluminum-Magnesium coatings)

- Reinforced edge configurations (5mm border wires)

Our modular production system enables batch orders from 50m² to 12,000m² with 14-day lead times.

Port Terminal Reinforcement Project

A 2023 coastal development utilized 8,400m² of heavy duty welded wire mesh (10 AWG, epoxy-coated) to:

- Reduce concrete usage by 18% through optimized slab design

- Withstand 6.5-ton forklift traffic cycles

- Maintain structural integrity in 8.2pH saltwater conditions

Cost Efficiency Analysis

Lifecycle comparisons show:

| Grade | Initial Cost | Maintenance/10yrs | Replacement Cycle |

|---|---|---|---|

| Commercial | $16.80 | $42.00 | 7 years |

| Industrial | $24.30 | $18.50 | 12 years |

Expanding Horizons for Heavy Welded Wire Solutions

Emerging applications in renewable energy (solar farm walkways) and flood control systems demonstrate heavy gauge welded wire's adaptability. Recent prototypes showcase 12 AWG meshes with 1,850 MPa tensile strength, enabling 35% weight reduction in aerospace-grade containment systems while maintaining structural requirements.

(heavy welded wire mesh)

FAQS on heavy welded wire mesh

Q: What are the common applications of heavy welded wire mesh?

A: Heavy welded wire mesh is widely used in construction, industrial fencing, machinery guards, and agricultural enclosures. Its durability makes it ideal for reinforcing concrete structures and securing high-traffic areas. The robust design withstands heavy loads and harsh environments.

Q: How does heavy duty welded wire mesh differ from standard wire mesh?

A: Heavy duty welded wire mesh features thicker gauges and stronger welds compared to standard mesh, ensuring greater load-bearing capacity. It is designed for demanding applications like animal cages, security barriers, and infrastructure projects. The enhanced strength provides long-term reliability under stress.

Q: What materials are used to make heavy gauge welded wire mesh?

A: Heavy gauge welded wire mesh is typically crafted from low-carbon steel or stainless steel for superior strength. Galvanized coatings are often applied to resist corrosion in outdoor or humid environments. Custom materials like PVC coatings may also be used for specialized needs.

Q: Can heavy welded wire mesh be customized for specific projects?

A: Yes, manufacturers offer customization in mesh size, wire diameter, and panel dimensions to suit project requirements. Options include varied coatings, edge reinforcements, or bespoke shapes. Consult suppliers to ensure compliance with industry standards like ASTM or ISO.

Q: How do I maintain heavy duty welded wire mesh in outdoor settings?

A: Regularly inspect for rust or damage and apply touch-up coatings if needed. Clean debris with mild detergent and water to prevent corrosion buildup. Galvanized or powder-coated variants require minimal maintenance for extended outdoor use.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA