Jan . 24, 2025 03:35 Back to list

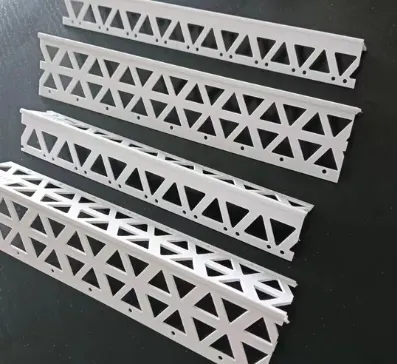

galvanized grating

Trustworthiness in choosing the right grating plate is built through understanding and adhering to industry standards. Building codes and safety regulations often mandate specific types of grating plates depending on the environment and load capacity. For instance, the Occupational Safety and Health Administration (OSHA) in the United States outlines safety codes for flooring and stairways that many industries must comply with. These regulations often dictate the standard size and specifications of the grating plates used, further emphasizing their importance. Real-world experience in using grating plates shows that projects benefit significantly from using standard sizes. When grating plates are produced according to set standards, installation becomes faster and more cost-effective. This efficiency results in reduced labor costs and minimizes material waste. Moreover, because the dimensions and quality are predictable, project managers can plan efficiently and mitigate risks associated with non-compliant materials. An industry insider from a construction firm recently noted the importance of using standard size grating plates in a large factory setup. The project involved installing extensive walkways and platforms. By opting for standardized grating plates, the team was able to swiftly implement the structures with minimal adjustments, reducing both time and unforeseen expenses. This illustrates the practical benefits of adhering to established size standards. In conclusion, understanding and utilizing grating plate standard sizes is a fundamental aspect of ensuring project success across various industries. By prioritizing expertise in production, authoritativeness through adherence to standards, and fostering trust through compliance, businesses can not only achieve operational efficiency but also enhance safety and reliability in their physical infrastructures. Whether in construction, manufacturing, or any other industry, selecting the right standard grating plate size maximizes performance while adhering to safety norms and reducing costs. This approach not only meets but often exceeds client expectations, delivering results that align with industry best practices.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA