Feb . 18, 2025 06:16 Back to list

galv wire mesh

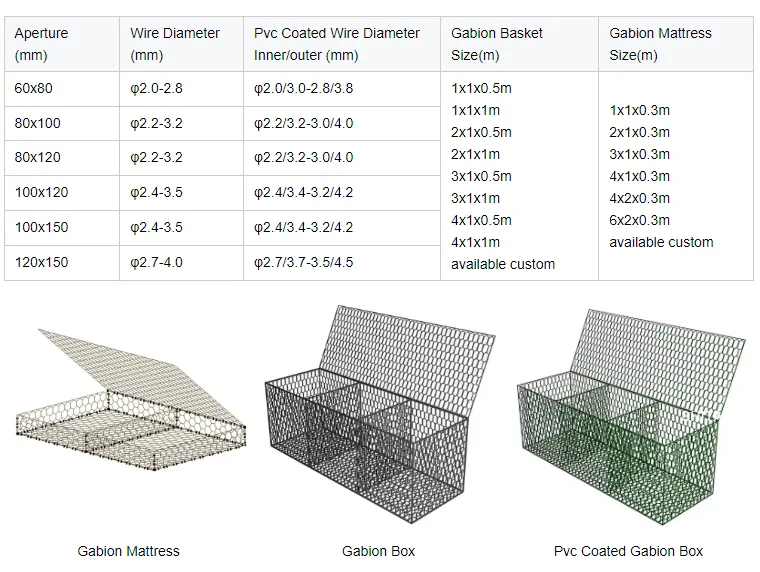

Moreover, in the field of infrastructure development, galv wire mesh remains a staple product. Civil engineers select it for projects such as highway fencing, erosion control, and drainage systems. Field experts confirm that its durability under varying stress conditions helps maintain public safety and infrastructure resilience, even in challenging environmental settings. The manufacturing process plays a crucial role in establishing the authority of galv wire mesh. Factories adhering to stringent international standards ensure the mesh delivered to sites is uniform, defect-free, and measured to precise dimensions. Quality assurance processes include rigorous corrosion resistance tests, thereby providing buyers with products they can trust to perform as expected under demanding conditions. Galv wire mesh also garners acclaim for its eco-friendliness. As environmental consciousness grows, stakeholders in the material supply chain advocate for sustainable manufacturing practices. The recyclability of galvanized wire mesh contributes to waste reduction and resource conservation. This echo-friendly stance aligns with sustainable development goals, making it an ethical choice for environmentally responsible projects. Understanding these diverse applications cements the reputation of galv wire mesh as a product born from expertise, and its widespread adoption is a testament to its authoritative standing in the materials industry. From its chemical resilience to its mechanical strength, the mesh remains a cornerstone product that epitomizes reliability and innovation. In summary, whether you are embarking on a personal project or are part of an expansive construction endeavor, selecting galv wire mesh signifies a commitment to quality and durability. Users and industry professionals alike continue to discuss its potential, paving the way for future advancements and innovations. Harnessing this valuable tool can significantly optimize both functional and aesthetic aspects of your projects, backed by the assurance of trust and expertise.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA