Feb . 20, 2025 09:42 Back to list

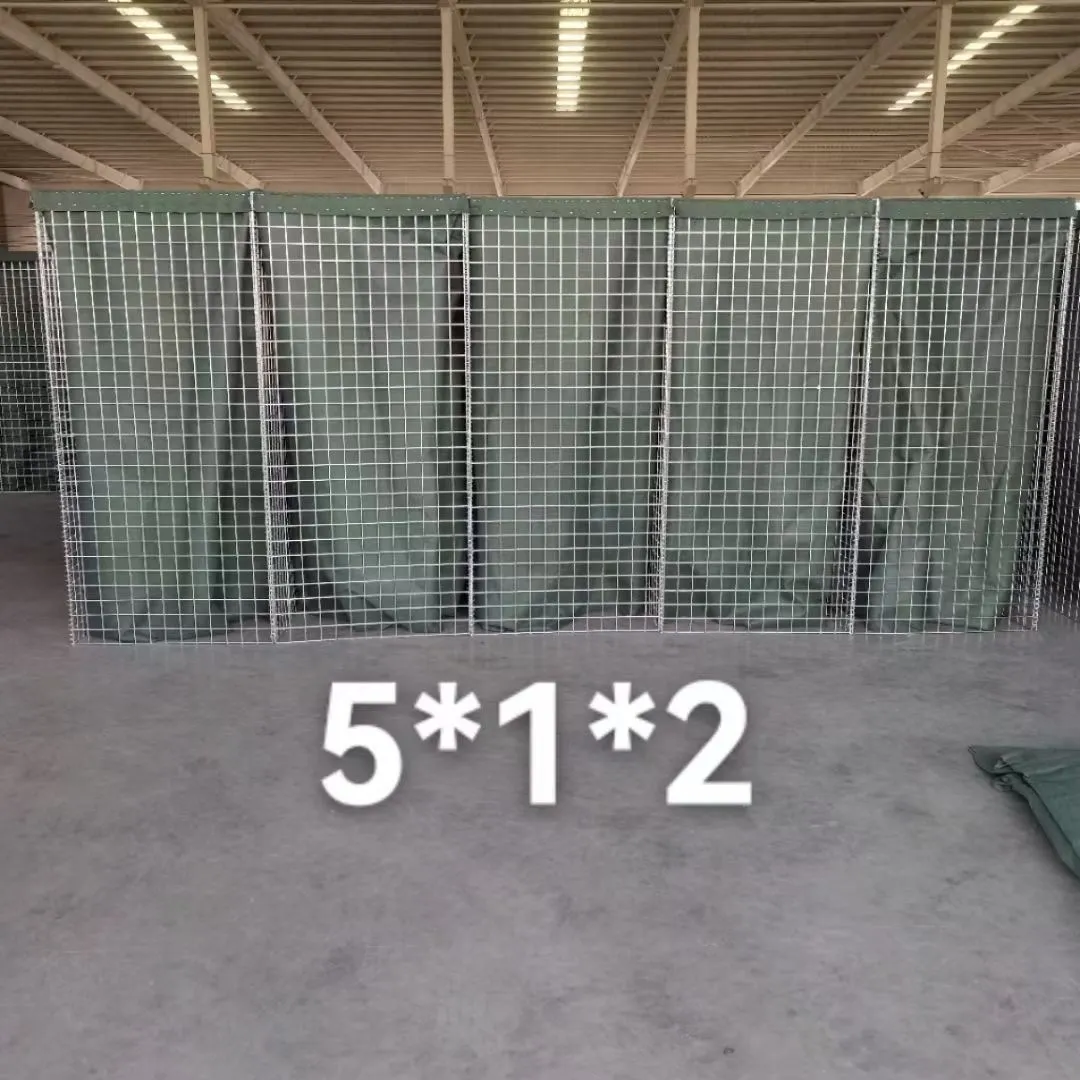

galvanized wire grid panels

Besides their practical uses, galvanized wire grid panels also contribute to environmental sustainability. The galvanization process is less energy-intensive compared to other metal coatings, and the panels themselves are often made from recyclable materials. This sustainable aspect is increasingly appealing to businesses and individuals seeking to minimize their environmental footprint. The aesthetics of galvanized wire grid panels should not be overlooked. Their sleek, metallic finish adds a modern touch to any space, making them a popular choice for contemporary interior designs. Whether used in urban landscapes or rustic settings, these panels complement a wide range of architectural styles, enhancing the overall visual appeal of a property. When selecting galvanized wire grid panels, it is important to consider the gauge of the wire and the size of the grid openings. Thicker gauges offer increased strength and are ideal for applications requiring additional support, while smaller grid openings are perfect for deterring smaller animals and pests. Consulting with a specialist can ensure that the right specifications are chosen to meet specific needs, optimizing both performance and cost-efficiency. Investing in high-quality galvanized wire grid panels from reputable suppliers can significantly impact their performance and longevity. Reputable manufacturers not only adhere to stringent quality control measures but also provide guarantees that offer peace of mind to buyers. It is advisable to seek out suppliers that have established a strong track record in the industry and can provide comprehensive after-sales support. In conclusion, galvanized wire grid panels represent a fusion of practicality and aesthetics, making them a highly sought-after choice across various sectors. Their resistance to corrosion, longevity, and versatile applications render them an essential product for modern infrastructure and design. As industries continue to evolve, the role of these panels in providing sustainable, efficient, and aesthetically pleasing solutions is likely to expand, cementing their status as a staple in innovative engineering and design.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA