Feb . 20, 2025 02:50 Back to list

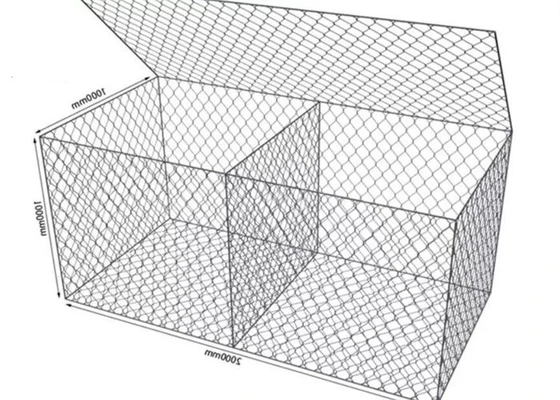

galvanized steel mesh panels

From an environmental standpoint, galvanized steel mesh panels are respected for their sustainability. The galvanization process itself is energy-efficient, and the longevity of the panels reduces the frequency of replacement, leading to less waste. At the end of their life cycle, these panels are fully recyclable, thus supporting sustainable practices in industries committed to minimizing their ecological footprint. Choosing the right galvanized steel mesh panel involves understanding specific project requirements and environmental conditions. Professionals in the industry should consider factors such as panel thickness, mesh size, and coating quality to ensure optimal performance. Consulting with experts or manufacturers can provide insights into innovative products tailored to contemporary needs, reflecting advancements in technology and material science. Moreover, it's essential to work with suppliers that adhere to industry standards and regulations, ensuring that the products meet quality benchmarks while providing reliable performance. Documentation and certifications from recognized authorities further enhance credibility and confidence in the product's suitability for various applications. In conclusion, galvanized steel mesh panels are invaluable assets across multiple domains due to their enduring properties and utility. Their comprehensive application, paired with expert consultation and sustainable practices, makes them a sound investment for projects demanding reliability and efficiency. As industries continue to evolve, so too does the potential of these panels, driven by innovation and an ongoing commitment to excellence in material sciences.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA