Feb . 07, 2025 01:03 Back to list

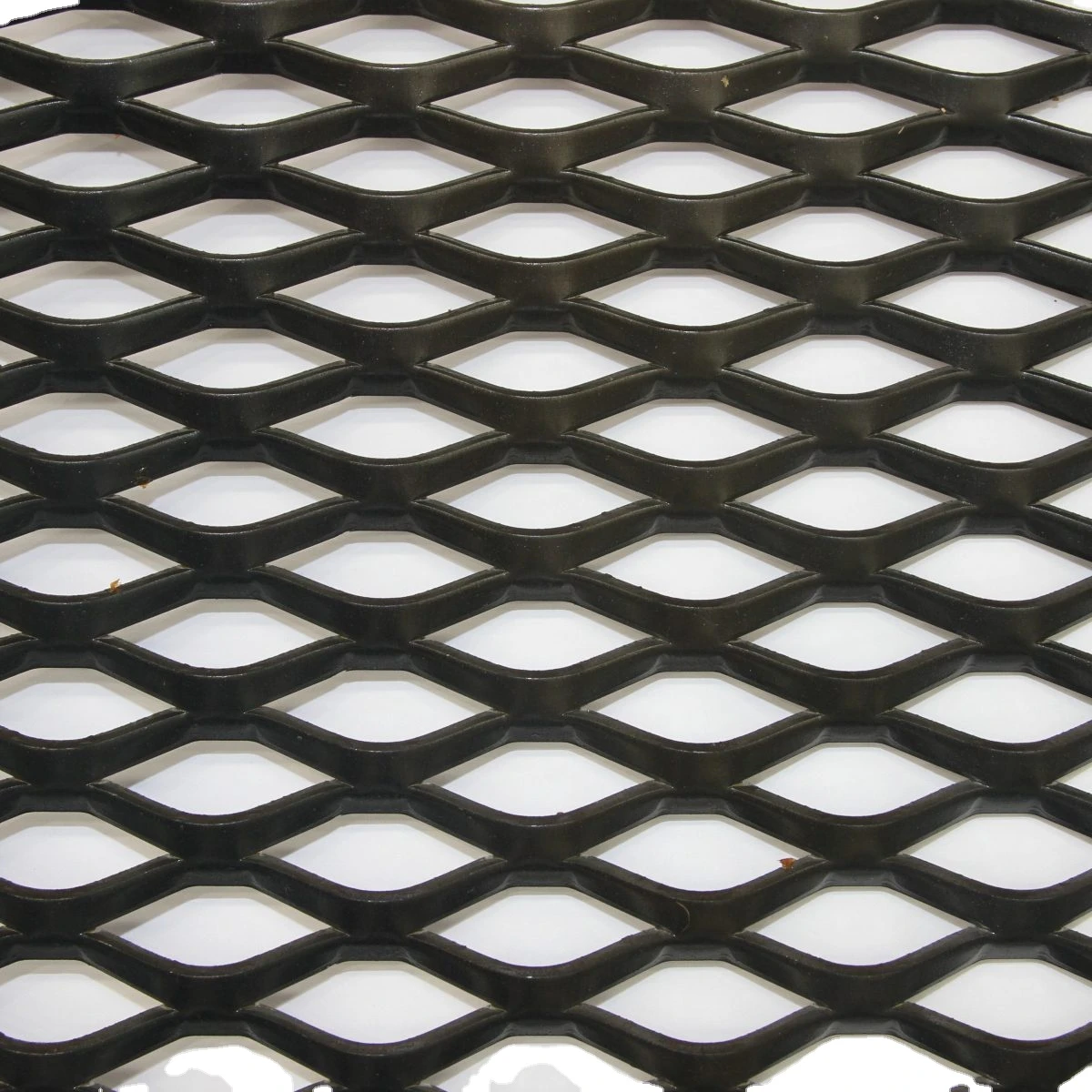

galvanized steel grate

The versatility of galvanized steel grates extends to customizable options that cater to specific project needs. Variations in thickness, size, and shapes are readily available, allowing for bespoke configurations that perfectly meet unique project specifications. This adaptability ensures compliance with varying safety standards, catering to diverse industrial demands while optimizing functionality. In terms of installation, galvanized steel grates offer ease and efficiency. Their lightweight nature simplifies handling and placement, reducing labor costs and installation time. Having overseen numerous installation projects, it's evident that the selection of galvanized over non-galvanized alternatives results in superior long-term performance and operational efficiency. Moreover, the upkeep of galvanized grates is markedly less intensive, demand minimal maintenance when compared to other materials, even when deployed in high-stress environments. A frequently overlooked aspect of galvanized steel grates lies in their sustainability. Zinc, used in the galvanization process, is a sustainable and recyclable metal, enabling these grates to contribute positively towards green building initiatives. This environmental consideration positions galvanized steel grates not only as a practical choice but also an eco-conscious one, aligning with contemporary demands for sustainable industrial practices. On an authoritative note, it's essential to highlight that reputable industry experts consistently advocate for the use of galvanized steel grates in numerous technical publications and industry reports. Their endorsements stem from extensive empirical research and field studies which validate the grates' enduring quality and structural benefits. Such extensive documentation ensures that the recommendations for their use are grounded in substantial professional credibility. In conclusion, galvanized steel grates are indispensable in contemporary industrial applications, delivering unmatched resilience, design flexibility, maintenance efficiency, and environmental responsibility. They offer a compelling proposition for facilities across multiple sectors, paving the way for durable, cost-effective, and strategically advantageous infrastructure solutions. With my expertise in the field and practical comprehension of these products, galvanized steel grates manifest as the optimal choice for anyone seeking functionality coupled with long-lasting performance.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA