Jan . 30, 2025 04:36 Back to list

Floor Drainage Trench Cover For High Quality Stainless Steel Serrated Steel Grating

In terms of trustworthiness and authority, galvanized serrated grating stands as a testament to engineering excellence. End-users can have confidence knowing that this material is tested and proven across various industries. It complies with stringent safety standards and regulations, ensuring it meets the required performance criteria. Whether for industrial giants or smaller projects, this grating maintains its reputation for reliability and effectiveness. For those considering galvanized serrated grating for their projects, it’s worth noting the cost-benefit aspect. While the initial investment may be higher than untreated grating, the reduced maintenance costs and extended lifespan provide a better return on investment. By minimizing replacements and repairs, businesses can allocate resources more efficiently, ultimately enhancing operational productivity and performance. Real-world experience shows that choosing the right grating can make a significant impact on a project's success. It's not just about compliance or technical specifications; it's about ensuring that the chosen materials align with the project's needs and constraints. Galvanized serrated grating meets these demands with a blend of durability, safety, and cost-efficiency, positioning it as a preferred choice for industry leaders. In summary, galvanized serrated grating is more than just a construction component; it's a key element that supports operational safety, efficiency, and longevity. Professionals seeking reliable, high-performance solutions will find this product invaluable, supported by its proven track record and adherence to high standards of manufacturing excellence. Whether for new constructions or retrofitting existing structures, it remains a wise investment for any forward-thinking entity.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

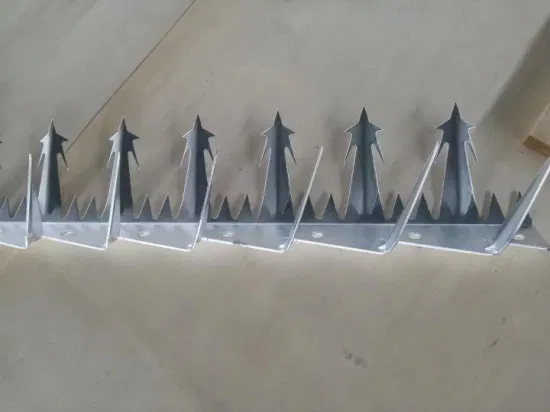

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA