Jan . 13, 2025 17:43 Back to list

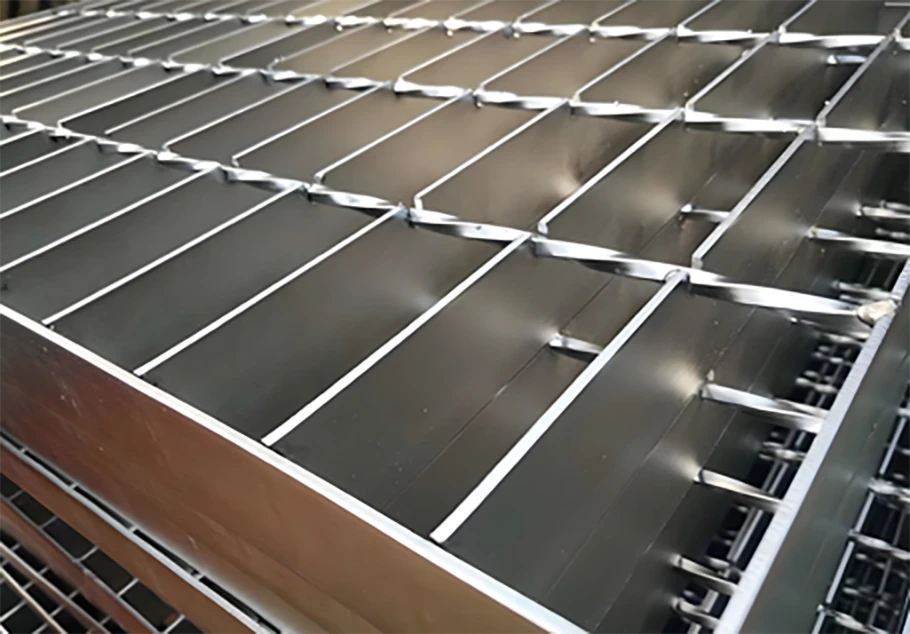

galvanized grating

The authority of a supplier can significantly influence the quality and performance of grating steps. When selecting a product, sourcing from well-established manufacturers who comply with international standards guarantees not only durability but also conformance with safety regulations. Companies with decades of experience often provide detailed consultation services, aiding customers in selecting the most suitable options for their specific needs, a testament to their commitment to quality and customer satisfaction. Trustworthiness comes into play when customers share testimonials and experiences about grating step products. These honest reviews serve as a beacon for potential buyers. Common feedback highlights the transformative impact of high-quality grating steps on pedestrian safety and accessibility. Users frequently commend the efficacy of anti-slip features and the ease of maintenance that quality grating steps provide. Additionally, the long-term cost efficiency associated with investing in high-grade materials proves appealing to budget-conscious buyers aiming for sustainable solutions. Choosing the right grating steps entails a thorough understanding of various factors, ranging from material properties to installation techniques. Combining experience, expertise, authority in production, and trustworthiness in reviews culminates in making informed decisions, ultimately leading to enhanced safety, durability, and aesthetic appeal in any setting.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA