Feb . 18, 2025 08:45 Back to list

function of wire gauze

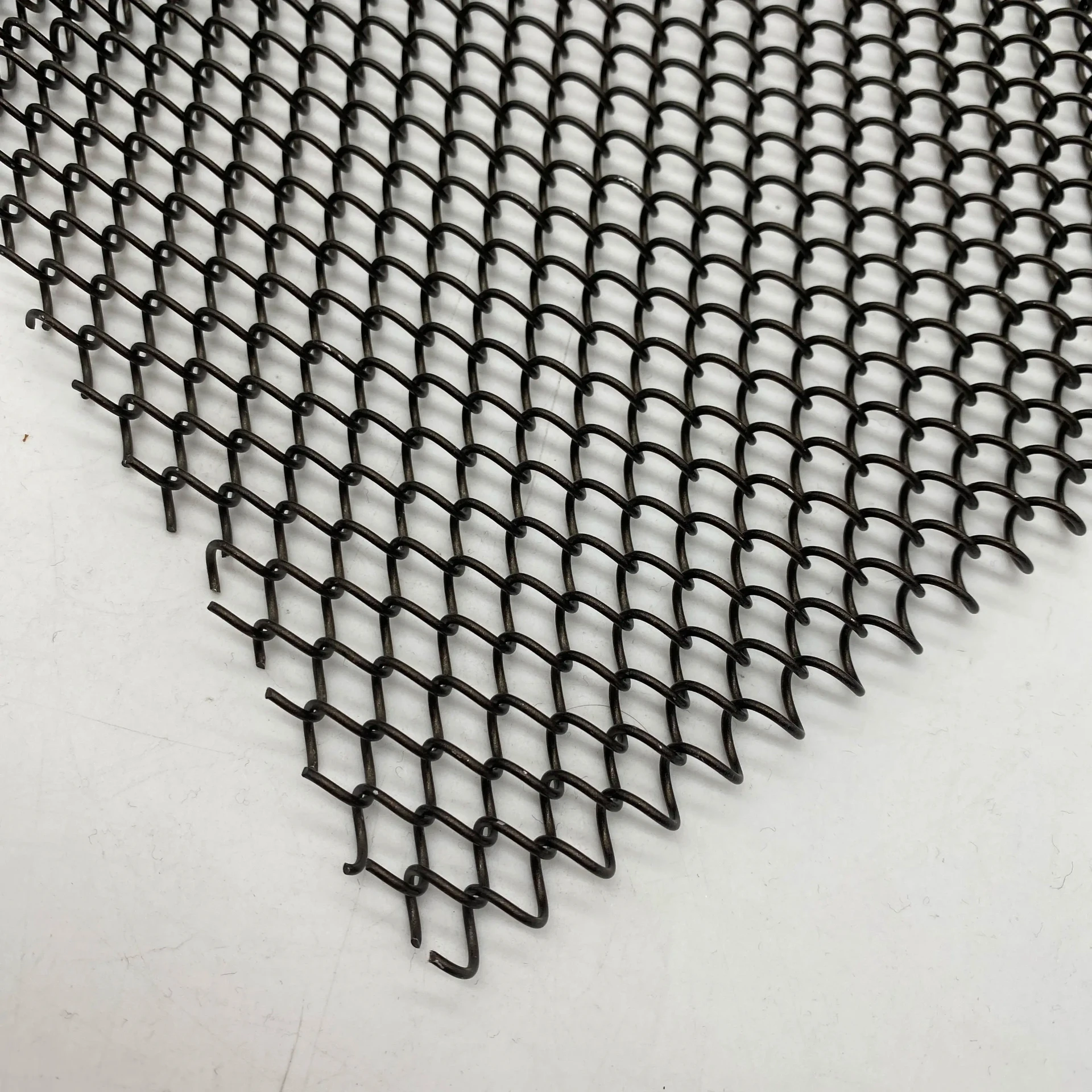

The domestic utility of wire gauze should not be underestimated, either. In everyday kitchen settings, wire gauze provides a makeshift trivet or cooling rack, demonstrating its versatility in protecting surfaces from hot cookware. Its utility in preventing burns and heat damage in day-to-day activities is a testament to its functional design and adaptability. Moreover, its role in preventing heat transfer is applicable in DIY projects, where it can be employed to diffuse heat from soldering irons or to create protective barriers during small-scale welding tasks. The tangible experience and trustworthiness associated with wire gauze in these settings highlight its practical value and reliability in everyday life. The expertise required to select the correct type of wire gauze for specific applications involves understanding mesh size, material composition, and heat resistance properties. For scientific or industrial usage, selecting a gauze with the appropriate mesh size is crucial for optimal support and heat distribution. Materials such as stainless steel or nichrome are preferred for their corrosion resistance and high-melting points. This expert knowledge not only enhances the effectiveness of wire gauze but also ensures safety and longevity in its application. In conclusion, the function of wire gauze is a testament to its multifaceted capabilities and indispensable nature across various domains. From the controlled environment of scientific laboratories to the robust demands of industrial applications, and further into everyday domestic settings, its role remains critical. As a tool trusted for its reliability, efficiency, and safety, wire gauze continues to stand as a paragon of design and utility. Through expert selection and proper application, its potential is fully realized, reinforcing its position as a cornerstone of technical and practical experiences.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA