Jan . 10, 2025 11:58 Back to list

Factory Supply Walkway Platform 6063 Anodized Aluminum Grating

When purchasing grating, consider the supplier's reputation and the quality guarantees they offer. A reputable seller should provide product specifications, load tables, and compliance with industry standards, such as the American Institute of Steel Construction (AISC) or the National Association of Architectural Metal Manufacturers (NAAMM) guidelines. These ensure that the grating you purchase will perform reliably and safely in its intended application. Equally important is selecting a supplier capable of providing custom solutions. Projects often demand specifically sized or shaped grating, or unique finishes to match architectural aesthetics or enhance performance characteristics. A good supplier will offer customization options, backed by engineering expertise, to help meet your precise requirements. Ultimately, trustworthiness in the grating supplier is key. Look for those who offer not just products, but complete solutions that include expert consultation and after-sales support. A well-informed decision will save both time and money while delivering an optimal solution tailored to the exact demands of your application. In conclusion, finding the right grating for sale involves a balance of material selection, configuration, manufacturer reputation, and customization capabilities. Each of these factors contributes to the performance, safety, and longevity of the grating in its end-use environment. By focusing on these crucial aspects, you'll make an informed purchase decision that satisfies both functional and budgetary requirements while ensuring the success of your project.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

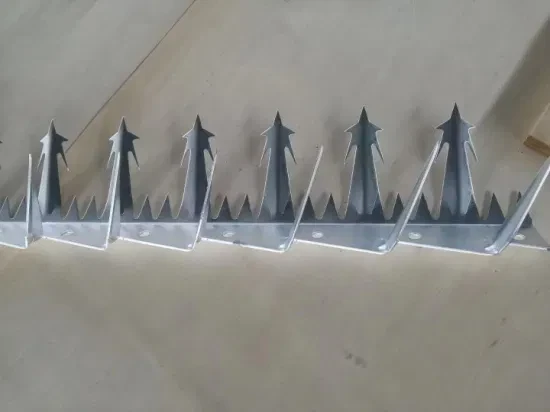

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA