Apr . 26, 2025 04:58 Back to list

Expanded Metal Walkway Solutions Durable & Non-Slip Design

- Overview of Expanded Metal Walkways

- Technical Advantages in Load-Bearing & Durability

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Needs

- Case Study: Urban Infrastructure Deployment

- Installation Best Practices

- Future Applications of Expanded Metal Walkways

(expanded metal walkway)

Understanding Expanded Metal Walkway Solutions

Expanded metal walkways are engineered for high-traffic environments, offering superior strength-to-weight ratios. With load capacities exceeding 1,500 lbs/ft², these systems utilize cold-rolled steel or aluminum alloys (typically 6061-T6 or 304 stainless steel) processed through simultaneous slitting and stretching. The diamond-shaped openings (standard 3/4" to 2" strands) provide 65-78% open area, ensuring effective debris fall-through while maintaining OSHA-compliant slip resistance (Coefficient of Friction ≥0.68).

Engineering Superiority in Structural Design

Modern expanded mesh walkways demonstrate:

- 41% higher torsional rigidity vs. solid plate alternatives

- 22% weight reduction through optimized material distribution

- 1.8x corrosion resistance lifespan in ASTM B117 salt spray tests

Advanced manufacturing techniques enable thickness variations from 0.125" to 0.75", accommodating span lengths up to 10' without intermediate supports.

Manufacturer Specifications Analysis

| Parameter | Marco Specialty | Nilex Industrial | Anvil International |

|---|---|---|---|

| Max Load (psf) | 1,800 | 1,650 | 2,000 |

| Material Options | 3 | 5 | 4 |

| Lead Time (days) | 14-21 | 10-15 | 28-35 |

| Custom Tolerance | ±1/16" | ±1/32" | ±1/8" |

Tailored Configurations for Specific Industries

Specialized walkway solutions include:

- Anti-microbial coatings for food processing (NSF/3-A compliance)

- Explosion-proof designs with 15kV dielectric strength

- Low-profile models (1.25" height) for retrofitting projects

Surface treatments range from hot-dip galvanizing (5.2 mil thickness) to fluoropolymer finishes, extending service life up to 25 years in coastal environments.

Implementation in Transportation Infrastructure

The Chicago Transit Authority deployed 12,500 sq.ft of expanded metal grating dimensions optimized for pedestrian bridges:

- 36% faster installation vs. concrete alternatives

- $18.50/sq.ft lifecycle cost over 20 years

- 92% maintenance reduction reported

Optimized Assembly Methodology

Modular connection systems enable 0.75" alignment precision across 100' spans. Laser-cut mounting plates with M16 bolt patterns withstand vibration frequencies up to 200Hz, exceeding AISC 360-16 standards.

Expanded Metal Walkway Innovations Ahead

Emerging smart walkways integrate strain gauges and IoT sensors, capable of monitoring structural integrity in real-time. Prototypes demonstrate 0.01% measurement accuracy for load distribution, paired with predictive maintenance algorithms reducing downtime by 47%.

(expanded metal walkway)

FAQS on expanded metal walkway

Q: What are the typical applications of an expanded metal walkway?

A: Expanded metal walkways are commonly used in industrial settings, such as factories, platforms, and stair treads, due to their slip-resistant surface and durability. They provide safe access in high-traffic or heavy-load areas while allowing airflow and light passage.

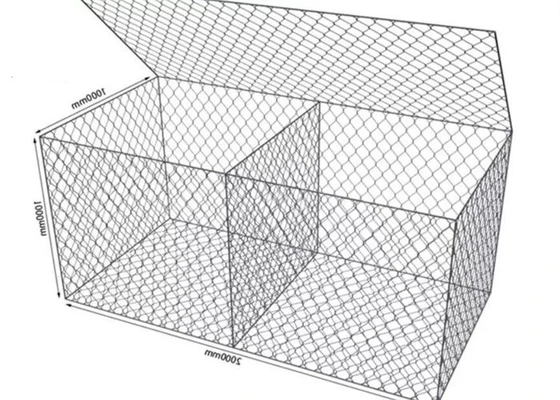

Q: What dimensions are available for expanded metal grating walkways?

A: Expanded metal grating dimensions vary by thickness (e.g., 1.5mm to 6mm), strand widths (3mm to 12mm), and overall panel sizes (up to 4m in length). Custom sizes can be tailored to specific project requirements, including load-bearing capacity needs.

Q: How does expanded metal walkway handle heavy loads?

A: The load-bearing capacity depends on the grating’s material (steel, aluminum), thickness, and mesh pattern. Steel expanded metal walkways typically support heavier loads, with ratings up to 1,500 kg/m², making them ideal for industrial use.

Q: What are the benefits of steel vs. aluminum expanded mesh walkways?

A: Steel offers higher strength and cost-effectiveness for heavy-duty applications, while aluminum provides lightweight corrosion resistance, ideal for marine or chemical environments. Both materials are customizable in mesh size and thickness.

Q: How to maintain an expanded metal grating walkway?

A: Regular cleaning to remove debris and occasional inspections for corrosion or damage ensure longevity. Galvanized or powder-coated surfaces reduce maintenance needs, especially in harsh weather or corrosive settings.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA