Feb . 13, 2025 00:26 Back to list

drywall corners

For those seeking the utmost precision and longevity in drywall corner finishes, expert tips from seasoned professionals underline the importance of environmental control—keeping the workspace at a consistent temperature and humidity level reduces the likelihood of compound cracking or setting improperly. Moreover, using high-quality tools such as corner rollers and professional-grade compounds ensures a refined finish, and investing in dust-free sanders can significantly cut down on clean-up time and health hazards associated with dust inhalation. Amateurs and professionals alike must understand that the longevity of drywall corners largely depends on meticulous preparation and patient, precise execution. For a quality finish, it is recommended to undertake multiple rounds of mudding and sanding. This layered approach not only conceals seams but also builds a sturdy, resilient structure that withstands daily wear and tear. The underlying philosophy among drywall experts is that time spent in preparation and detail-oriented execution pays off in the form of a flawless finish. Trust in the process is cemented by adhering to expert-recommended practices and continually updating one’s knowledge with the latest product advancements and techniques. This ensures that every corner of a space does not just meet expected standards but exceeds them in a way that shuns the ordinary and embraces exceptional quality. Ultimately, achieving impeccable drywall corners is an art form, reflecting a blend of experience, authority, and trustworthiness. This is achieved by choosing high-quality materials, employing tried-and-tested methods, and committing to painstaking craftsmanship. By following these principles, one can transform drywall corner finishing from a daunting task to a rewarding pursuit, producing beautiful, lasting results that speak volumes about the skill and care invested in the craft.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

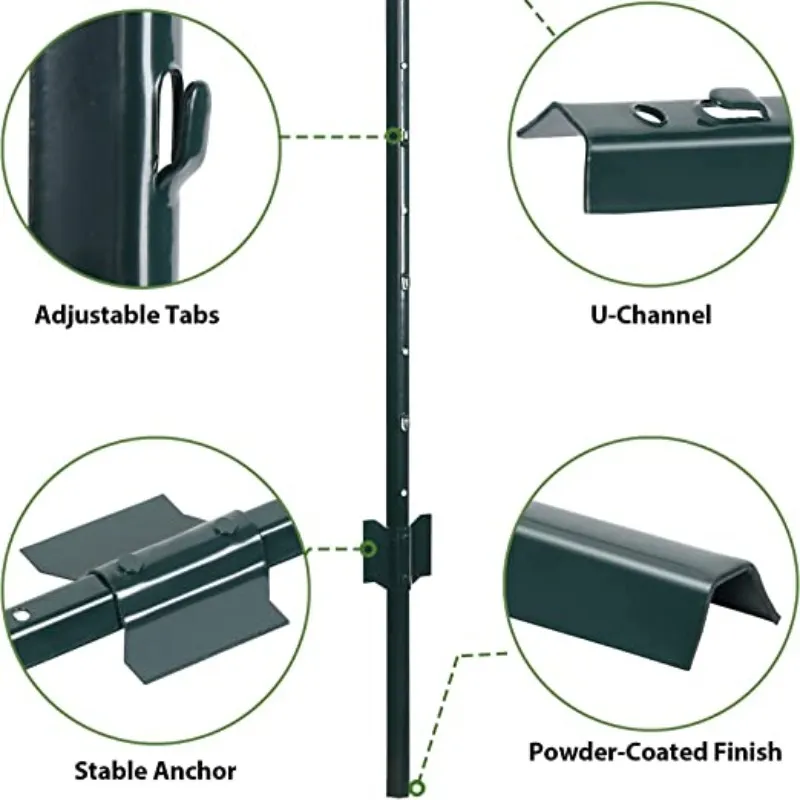

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

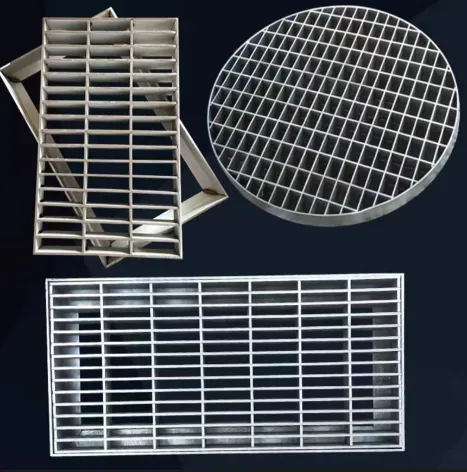

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA