Jan . 14, 2025 09:47 Back to list

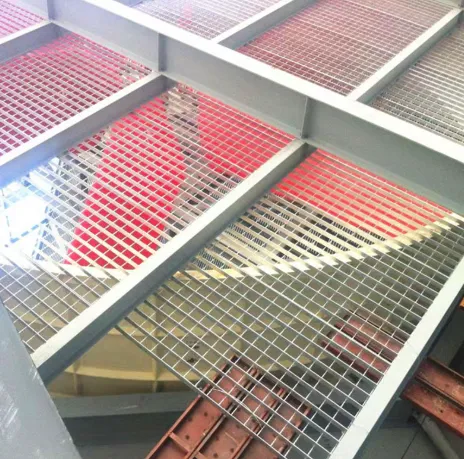

drain trough grating

The trustworthiness of a drain trough grating supplier is often reflected in their transparency concerning product testing and customer feedback. Openness about the rigorous tests undergone by their products – from load testing to corrosion assessments – plays a critical role in earning clients' trust. Furthermore, being able to provide references or case studies from previous installations can give prospective customers a real-world insight into the grating’s performance. This authenticity builds a solid foundation of trust, essential for long-term industry relationships. When considering the economic implications, investing in high-quality drain trough gratings may appear significant, but the long-term benefits outweigh initial costs. Effective drainage systems prevent costly water damage to infrastructure, reduce maintenance requirements, and enhance safety by preventing hazardous conditions like flooding. The selection of reliable trough gratings thus becomes an investment in the durability and safety of the entire drainage infrastructure. Moreover, incorporating sustainable material options not only supports environmental goals but can also align with corporate social responsibility agendas, presenting a positive brand image. By understanding the nuanced details that go into effective drainage solutions, project managers, engineers, and architects can make informed decisions regarding the inclusion of drain trough gratings. For any new development or refurbishment project, assessing the unique site conditions and consulting with experts can lead to the selection of gratings that are optimized for performance, longevity, and safety. Ultimately, drain trough gratings are more than mere construction accessories – they are foundational components that underpin the success of drainage infrastructure. Through expertise in design, quality assurance in material selection, adherence to international standards, and a commitment to transparency, the right grating solution enhances the efficacy and safety of any project it is deployed in.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA