Mar . 04, 2025 10:52 Back to list

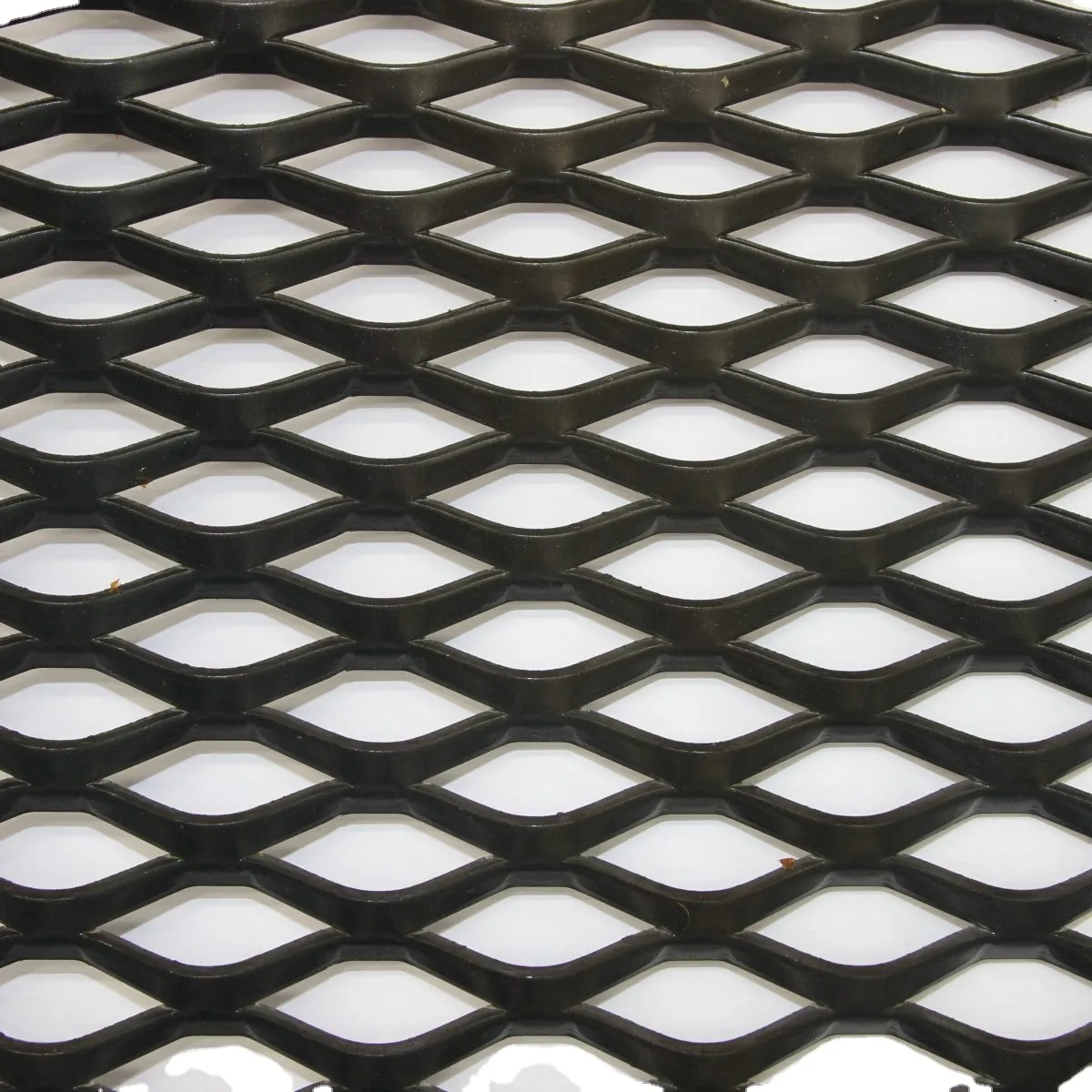

concrete wire mesh for sale

Moreover, environmental conditions and project-specific challenges are also significant considerations. Factors such as exposure to moisture, temperature fluctuations, and chemical environments can influence the choice of mesh. For example, galvanized or epoxy-coated wire mesh products offer enhanced resistance to corrosion, making them ideal for projects subject to harsh environmental conditions. When sourcing concrete wire mesh for sale, cost-effectiveness should be balanced with quality and longevity. The initial investment in high-quality mesh can translate into substantial savings in long-term maintenance and repair costs. An often overlooked advantage is the reduced labor cost associated with installing premium mesh products, which often come in larger, more easily manageable panels. In terms of authoritativeness, concrete wire mesh has been backed by decades of research and real-world application. Numerous engineering studies and construction case analyses validate its efficacy in improving structural performance. Consulting with experts in structural engineering and construction can provide deeper insights into product selection and application techniques, further enhancing project outcomes. Trustworthiness in the context of purchasing concrete wire mesh involves transparency from suppliers, clear communication of product specifications, and adherence to project timelines. Reputable suppliers will offer comprehensive support and guidance, ensuring clients receive not only the physical product but also the assurance of performance and reliability. Ultimately, concrete wire mesh stands as a cornerstone of modern construction practices. Its strategic application can significantly enhance the durability and resilience of concrete infrastructures, providing peace of mind for builders and occupants alike. By investing in quality mesh products, coupled with professional installation expertise, construction projects can achieve superior standards in safety and functionality.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA