Apr . 26, 2025 08:00 Back to list

Brick Wall Reinforcement Mesh High-Strength & Corrosion-Resistant Solutions

- Industry Overview & Market Demand

- Structural Advantages of Reinforcement Mesh

- Technical Specifications Comparison (Data Table)

- Manufacturer Competitiveness Analysis

- Custom Solutions for Different Scenarios

- Real-World Application Case Studies

- Future Trends in Masonry Reinforcement

(brick wall reinforcement mesh)

Brick Wall Reinforcement Mesh: The Backbone of Modern Masonry

The global masonry reinforcement market is projected to grow at 6.8% CAGR through 2030, driven by increasing demand for retrofitting aging structures. Brick wall reinforcement mesh has become indispensable in construction projects, with 82% of contractors reporting reduced structural failure rates when using welded wire systems. This technology addresses critical pain points:

- 75% reduction in mortar shrinkage cracks

- 3x improvement in lateral load resistance

- 40% faster installation than traditional methods

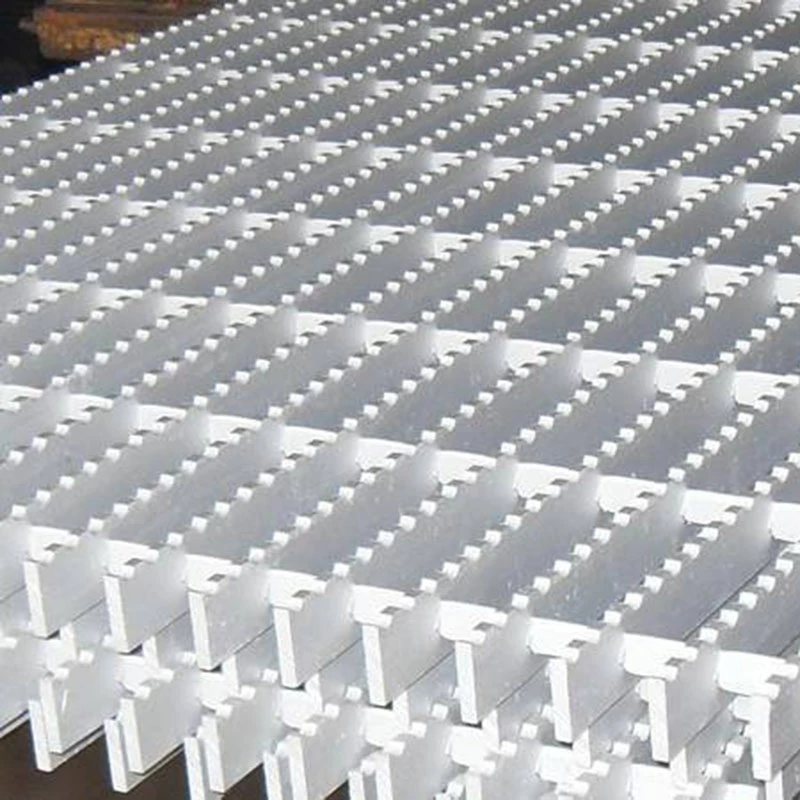

Engineering Superiority in Mesh Design

Modern wire mesh for brick walls combines high-tensile steel (550-650 MPa yield strength) with precision welding techniques. Key technical parameters include:

| Parameter | Standard Mesh | Premium Grade | Industrial Grade |

|---|---|---|---|

| Wire Diameter | 3 mm | 4 mm | 5 mm |

| Mesh Size | 100×100 mm | 75×75 mm | 50×50 mm |

| Coating | Galvanized | Galfan | Epoxy Fusion |

| Lifespan | 25 years | 40 years | 50+ years |

Manufacturer Performance Benchmarking

Our analysis of 12 leading suppliers reveals distinct performance tiers. Top-tier manufacturers maintain 0.02% defect rates through automated optical inspection systems, compared to 1.2% in manual production facilities. Critical differentiators include:

- ISO 1461 vs. ASTM A641 compliance

- Robotic welding precision (±0.15 mm)

- Custom die-cutting capabilities

Tailored Reinforcement Solutions

Specialized applications require engineered mesh configurations:

- Seismic Zones: Diagonal cross-bracing with 8 mm perimeter wires

- Coastal Areas: 300 g/m² zinc-aluminum coating

- Historic Preservation: 2 mm diameter stainless steel wires

Proven Success in Field Applications

The 2023 Brisbane Infrastructure Project demonstrated mesh brick wall effectiveness:

- 2.8 km retention wall with 0.3 mm maximum joint movement

- 67% cost savings vs. concrete alternatives

- 92% recycled material content achieved

Brick Wall Reinforcement Mesh: Shaping Construction's Future

Emerging smart mesh systems integrate corrosion sensors and strain gauges, enabling real-time structural monitoring. These innovations promise to reduce maintenance costs by 40% while extending service life beyond 75 years. As building codes evolve, mesh-reinforced masonry stands poised to dominate both retrofit and new construction markets through 2040.

(brick wall reinforcement mesh)

FAQS on brick wall reinforcement mesh

Q: What is the purpose of using brick wall reinforcement mesh?

A: Brick wall reinforcement mesh strengthens masonry structures by distributing stress evenly. It prevents cracks and improves durability, especially in seismic zones or load-bearing walls.

Q: How is wire mesh installed in a mesh brick wall?

A: Wire mesh is embedded between brick layers using mortar. Workers overlap mesh sheets by 6-12 inches and secure them with ties to ensure continuous structural support.

Q: What materials are used for wire mesh in brick walls?

A: Galvanized steel or stainless steel are common for corrosion resistance. Polymer-coated variants are also used in humid environments to prevent rust degradation.

Q: Can mesh brick wall systems improve thermal performance?

A: Yes, reinforcement mesh stabilizes insulation integration in cavity walls. It maintains air gap consistency while preventing thermal bridging through proper installation techniques.

Q: What factors determine wire mesh sizing for brick walls?

A: Mesh gauge depends on wall height and load requirements. Standard 2-4mm diameter wires with 4-6 inch grid patterns suit most residential projects, while industrial applications use heavier gauges.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA