Feb . 19, 2025 04:00 Back to list

black plastic coated wire mesh panels

The advantages don't stop at construction and industrial applications. Agricultural uses also abound, where these panels provide safe and durable enclosures for livestock and poultry, as well as protection for crops from wildlife. Their resistance to corrosion is particularly beneficial in these settings, where conditions can be especially challenging. Trustworthiness in products is paramount, and black plastic coated wire mesh panels have consistently proven their reliability. End-users report significant reductions in maintenance costs, credited to the panels' resilience and the protection the plastic coating provides. This feedback reinforces the panels' reputation as a sound investment, with many industry experts recommending them for projects demanding long-term, low-maintenance solutions. The market for these panels continues to expand, with innovations in polymer technology promising even more robust coatings that could further extend their lifespan and functionality. As this sector evolves, staying informed about the latest advancements is crucial for those looking to leverage the full potential of wire mesh solutions. Despite their numerous benefits, it's important for buyers to consider their specific needs and consult with suppliers or industry professionals when selecting wire mesh panels. Factors such as mesh size, wire gauge, and coating thickness can significantly influence the performance of the panels in different applications. Consulting with experts ensures that the chosen product perfectly matches the intended use, maximizing the return on investment. In conclusion, black plastic coated wire mesh panels epitomize a versatile, durable, and aesthetically pleasing solution for a wide range of applications. Their widespread adoption across industries is a testament to their impressive capabilities and dependable performance. By combining technical expertise with first-hand experience, we can appreciate the full scope of benefits these panels offer, making them an essential component in modern engineering and design.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

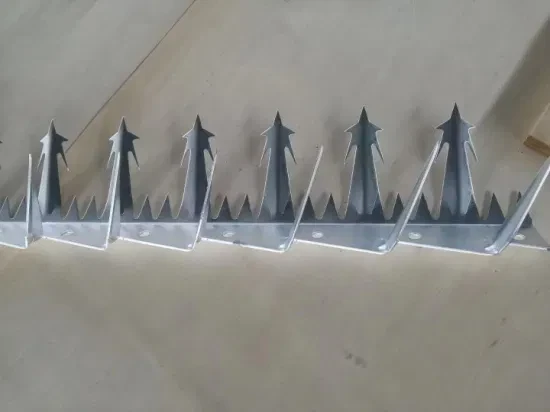

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA