Jan . 19, 2025 04:04 Back to list

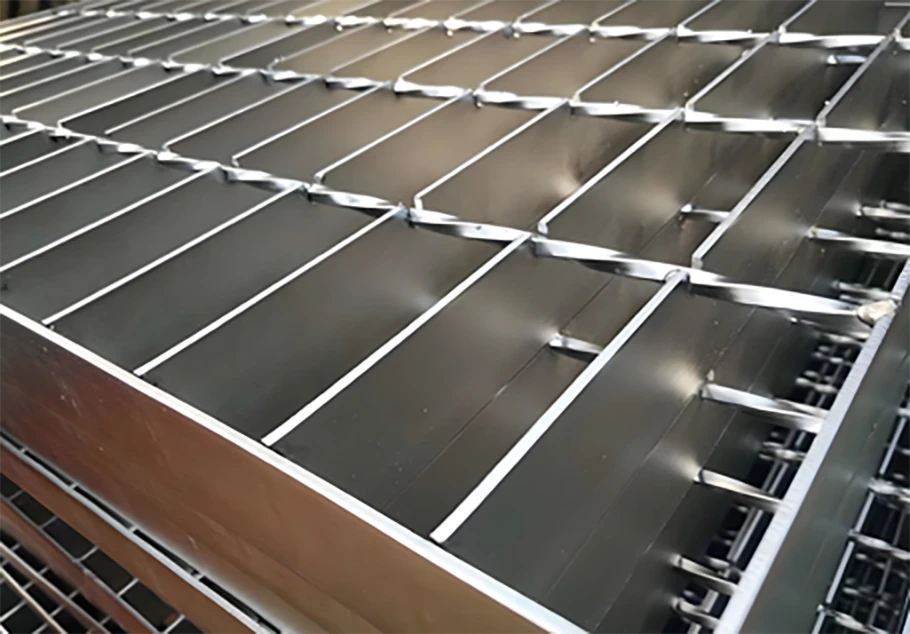

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

Furthermore, the economic aspects of bearing bar grating are noteworthy. Its longevity and minimal maintenance requirements translate into long-term cost savings. Unlike traditional flooring options that may require frequent replacement or repair, bearing bar grating is designed to withstand harsh conditions over extended periods, thus lowering operational costs and enhancing productivity with fewer interruptions. From an expert perspective, the selection of suitable bearing bar grating should be a meticulous process. Factors such as load requirements, environmental conditions, and specific industry regulations must be carefully evaluated. Consulting with specialized manufacturers can provide valuable insights and guidance, ensuring the selection of the most appropriate grating solution that guarantees safety, durability, and compliance with industry standards. Trustworthiness is also a fundamental factor in the procurement of bearing bar grating. It is vital to source materials from reputable manufacturers who adhere to stringent quality control processes. Certifications and compliance with international standards serve as indicators of quality and reliability, providing peace of mind to businesses that their infrastructure investments are sound and secure. In summary, bearing bar grating stands out as a superior industrial solution, combining strength, versatility, and economic advantages. Its ability to adapt to a variety of environments, coupled with its safety features and customization options, makes it an indispensable choice for numerous industries. By prioritizing quality and relying on expert guidance, businesses can leverage this robust product to enhance operational efficiency and ensure a safe working environment.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA