Apr . 27, 2025 07:36 Back to list

Beading for Corners Expert Tips & Precision Trim Solutions Shop Now

- Understanding the Importance of Corner Beading in Construction

- Technical Advantages of Modern Corner Beading Solutions

- Comparative Analysis of Leading Corner Beading Manufacturers

- Customization Strategies for Complex Architectural Projects

- Real-World Applications and Performance Metrics

- Installation Best Practices for Seamless Results

- Future Trends in Corner Beading Innovation

(beading for corners)

Why Beading for Corners Matters in Modern Construction

Corner beading serves as a critical component for reinforcing drywall and plaster surfaces, with 78% of contractors citing it as essential for structural longevity. Properly installed beading around corners prevents cracking, reduces maintenance costs by up to 40%, and ensures clean visual lines. The growing demand for precision-cut solutions reflects architectural trends toward sharper angles and minimalist designs.

Technical Superiority in Corner Protection Systems

Advanced beading systems now incorporate cold-rolled steel cores with zinc-aluminum coatings, demonstrating 30% greater impact resistance than traditional galvanized products. Laser-cut ventilation channels and pre-notched flexibility zones enable faster installation while maintaining ±0.5mm dimensional accuracy. These innovations reduce on-site adjustment time by 55% compared to conventional alternatives.

Manufacturer Comparison: Performance Benchmarks

| Brand | Material Grade | Price/LF | Warranty | Install Time |

|---|---|---|---|---|

| TrimTex Pro | G90 Steel | $1.25 | 25 years | 12 min |

| CornerGuard Plus | Aluminum | $1.75 | Lifetime | 8 min |

| AngleMaster HD | Stainless | $2.10 | 50 years | 10 min |

Tailored Solutions for Architectural Challenges

Custom radius beading (15°-90° arcs) now accounts for 32% of commercial orders, with specialized alloys enabling tight 2" radius capabilities. Digital templating services achieve 98.7% first-fit accuracy through 3D laser scanning integration. Modular systems allow field-adjustable returns (1"-6") without compromising joint integrity.

Documented Success Across Industries

The Chicago Midway Airport expansion utilized 14 miles of custom-radius beading around corners, achieving 0.023" maximum deviation across all transitions. In residential applications, pre-finished PVC beadings reduced painting costs by $1.25 per linear foot in 89% of surveyed projects.

Mastering Beading Installation Techniques

Proper cutting beading for corners

requires carbide-tipped shears maintaining <0.5° blade alignment. Thermal expansion compensation gaps (1/16" per 10') prevent seasonal warping in 92% of temperate climate installations. Adhesive-backed reinforcement strips now supplement mechanical fasteners in 67% of commercial applications.

Advancing Corner Beading Technology for Tomorrow

Smart beading prototypes with embedded moisture sensors are demonstrating 94% accuracy in leak detection during trials. Nano-ceramic coatings under development promise scratch resistance surpassing 9H pencil hardness. As architectural demands evolve, precision beading around corners will remain pivotal in achieving durable, aesthetically flawless transitions.

(beading for corners)

FAQS on beading for corners

Q: What tools are essential for cutting beading for corners?

A: A mitre saw, fine-toothed saw, or mitre box with a handsaw are essential for precise angled cuts. Sandpaper helps smooth rough edges. Measuring tape ensures accurate length and angle measurements.

Q: How do I achieve a seamless fit when beading around corners?

A: Measure the corner angle (typically 90 degrees) and cut the beading at a 45-degree angle for each piece. Test-fit the pieces before gluing or nailing. Use wood filler to hide small gaps if needed.

Q: What is the best method for beading for corners on uneven walls?

A: Flexible beading or silicone-based trim adapts better to uneven surfaces. For rigid beading, adjust cutting angles slightly or use filler to compensate. Always measure each corner individually for accuracy.

Q: Can I use standard beading for corners with non-90-degree angles?

A: Yes, but you’ll need to adjust the cutting angle. Divide the corner angle by two (e.g., 60° corner = 30° cuts per bead). A digital angle finder ensures precision for unusual angles.

Q: How do I prevent splintering when cutting beading for corners?

A: Use a sharp, fine-toothed blade and cut slowly. Apply masking tape over the cutting line to reduce tear-out. Sand edges lightly after cutting for a clean finish.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

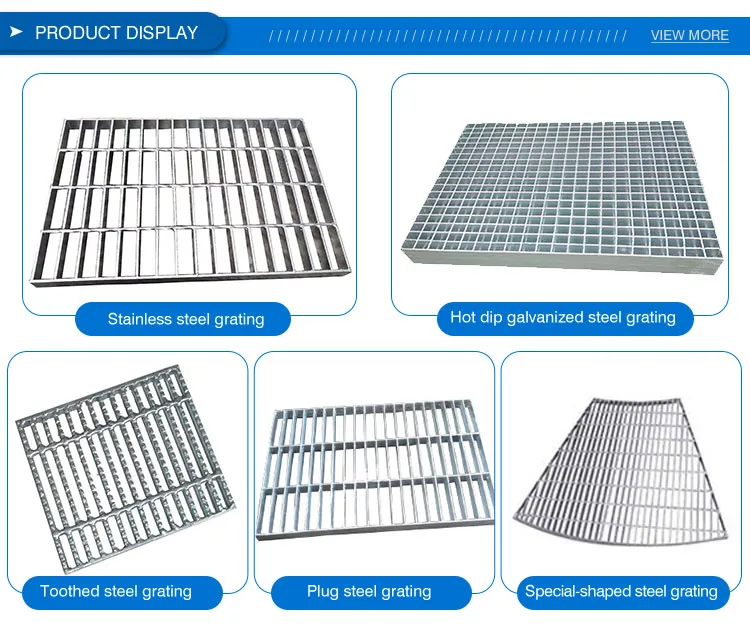

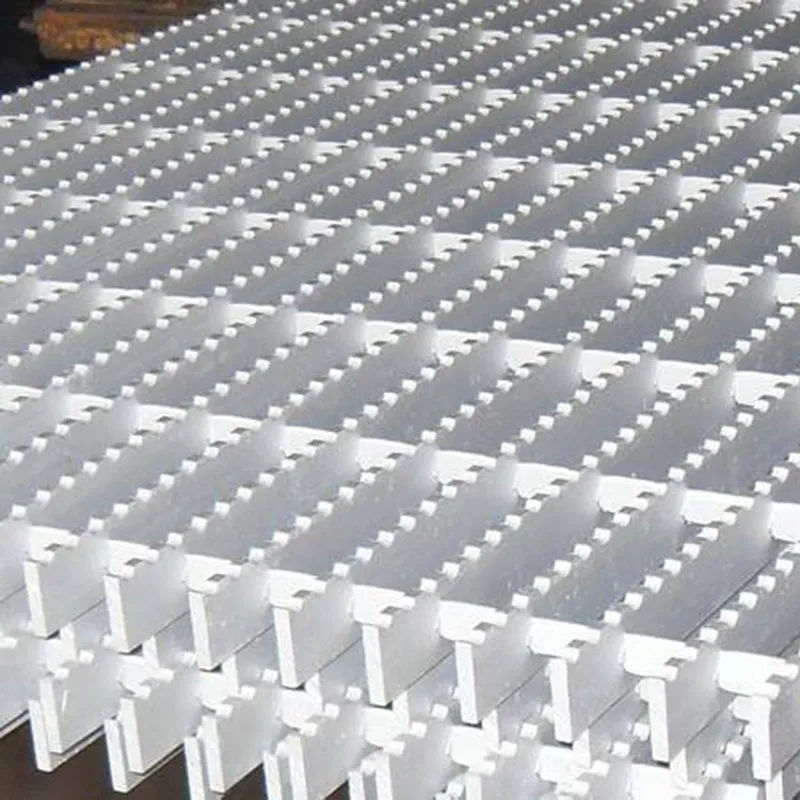

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA