Feb . 13, 2025 18:57 Back to list

bead corner drywall

Another key factor in successfully using corner bead drywall is understanding and implementing a thorough quality control process. A proper inspection before installation ensures that the beads are uniformly straight and free from defects, preventing complications during the installation phase. Additionally, post-installation, inspecting the continuity of the joint compound and the uniformity of the surface is critical to delivering a flawless finish. Throughout my career, consistent collaboration with quality control teams has guaranteed that every corner is crisp, every edge is aligned, and the overall aesthetic remains uncompromised. In terms of aligning with evolving sustainability concerns, choosing corner beads made from recyclable materials can significantly contribute to a project’s eco-friendliness. Vinyl corner beads, for instance, are often made from recycled content, and after the life cycle of the building, these materials can be further recycled. This approach aligns with global efforts towards reducing construction waste and promoting sustainable building practices. Overall, corner bead drywall is more than just a finishing element; it is an essential part of making environments livable, aesthetically pleasing, and safe. For professionals in the field, understanding the varied applications, materials, and latest developments ensures optimal results, providing both beauty and practicality. Emphasizing the expertise required in selecting, installing, and finishing corner beading can significantly enhance the overall quality and reputation of a project, ensuring it thrives in both function and design.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

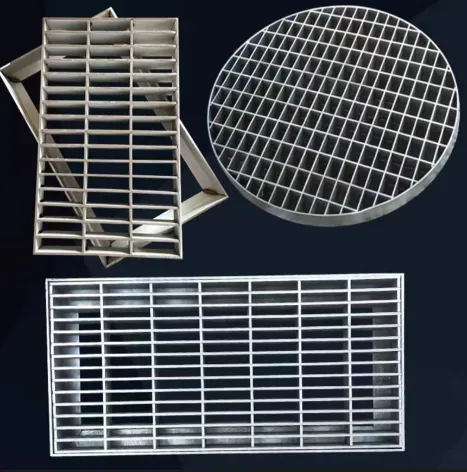

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA