Jan . 23, 2025 03:10 Back to list

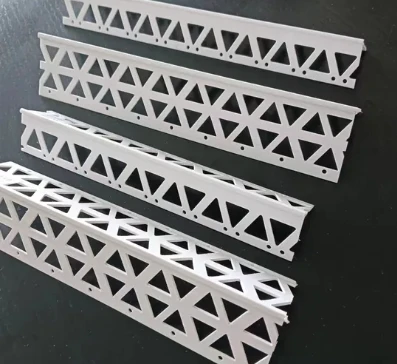

aluminum grating manufacturers

Trustworthiness encompasses transparency in communication, consistency in product delivery, and adherence to ethical business practices. Choosing a manufacturer with a reputation for reliability ensures peace of mind, knowing that the products will arrive as specified, within the agreed timelines, and without hidden complications or costs. Trust is further reinforced by warranties, post-sale support, and clear channels for customer service, indicating a manufacturer’s readiness to back their products and assist in any issues that may arise throughout the product’s lifespan. The competitive edge of leading bar grating manufacturers lies in their innovation and customization capabilities. Today's industrial and architectural designs demand unique solutions. Thus, manufacturers who offer a range of materials such as carbon steel, stainless steel, and aluminum, as well as custom finishes, differentiate themselves in the market. They go beyond standard offerings to provide corrosion-resistant coatings or aesthetic enhancements, which can be crucial for outdoor or visually appealing applications. Finally, in investigating a bar grating manufacturer, potential clients should look into testimonials, project case studies, and reviews from previous clients or third-party sources. This provides insights into the manufacturer’s performance and satisfaction levels that other customers have experienced. An honest assessment by past clients can highlight strengths and potential concerns, guiding others to make informed purchasing decisions. In conclusion, selecting a bar grating manufacturer is not just about finding a supplier, but establishing a partnership with a company that exemplifies experience, expertise, authoritativeness, and trustworthiness. To ensure optimal performance and longevity of bar grating installed in any project, choosing a manufacturer that adheres to these core principles is vital. In doing so, project managers, engineers, and procurement specialists can secure reliable materials that meet their specific application needs, thereby ensuring safety, efficiency, and success in their endeavors.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA