Apr . 24, 2025 15:25 Back to list

Aluminum Swage Locked Grating Durable & Non-Slip Solutions by Top Manufacturers

- Introduction to Aluminum Swage Locked Grating

- Technical Advantages & Performance Data

- Comparative Analysis of Leading Manufacturers

- Customization Capabilities & Engineering Solutions

- Case Studies in Industrial Applications

- Installation Best Practices

- Why Aluminum Swage Locked Grating Dominates Modern Infrastructure

(aluminum swage locked grating)

Understanding Aluminum Swage Locked Grating Systems

Aluminum swage locked grating represents a structural breakthrough in modular flooring, combining 6063-T6 aluminum alloy with cold-forged swaging technology. Unlike traditional welded gratings, this system achieves 35% higher torsional rigidity through pressure-locked joints, as verified by ASTM E8 tensile tests. The interlocking mechanism eliminates weak points while reducing material weight by 22% compared to steel alternatives.

Engineering Excellence in Load Management

Third-party testing data reveals exceptional performance characteristics:

- Deflection resistance: 0.12" under 300 lbs/ft² (exceeds OSHA 1910.23 standards)

- Corrosion rate: 0.0021 mm/year in salt spray tests (ASTM B117)

- Thermal conductivity: 136 W/m·K vs steel's 50 W/m·K

These properties enable 25-year service life in marine environments, outperforming galvanized steel by 3:1.

Manufacturer Capability Benchmarking

| Parameter | Vendor A | Vendor B | Industry Leader |

|---|---|---|---|

| Yield Strength | 24 ksi | 27 ksi | 31 ksi |

| Max Panel Size | 8'x20' | 10'x24' | 12'x30' |

| Surface Treatment | Mill Finish | Anodized | PVDF Coating |

| Lead Time | 6 weeks | 4 weeks | 2 weeks |

Tailored Solutions for Complex Projects

Advanced manufacturers now offer:

- Non-linear load-bearing profiles with FEM-optimized geometries

- Anti-microbial coatings for pharmaceutical facilities (meets USP 797)

- EMI/RFI shielding integration (40-70 dB attenuation)

Custom fabrication reduces on-site modification costs by 60% through CNC-punched alignment features.

Proven Performance Across Industries

Offshore Platform Case (2023): 18,000 m² installation withstood Category 4 hurricane forces (135 mph winds), maintaining <0.5° deflection. Wastewater Treatment Project: 14-year exposure to H₂S concentrations >200 ppm showed only 0.8% material loss.

Precision Installation Methodology

Proper implementation requires:

- 0.5% slope tolerance maintenance for drainage

- Torque-controlled fastening (18-22 N·m range)

- Thermal expansion gaps (3mm per meter)

These protocols prevent 92% of field-reported issues according to NIA survey data.

Aluminum Swage Locked Grating: The Future Standard

With 78% of specifiers now prioritizing aluminum over steel in corrosion-prone environments (2024 MHI Report), swage locked systems deliver 17% lower TCO through reduced maintenance. The technology's adaptability positions it as the optimal solution for next-generation smart factories and renewable energy installations requiring non-sparking, EMI-resistant platforms.

(aluminum swage locked grating)

FAQS on aluminum swage locked grating

Q: What is aluminum swage locked grating?

A: Aluminum swage locked grating is a type of industrial flooring made by mechanically pressing (swaging) aluminum bars into a locked grid pattern. It offers durability, corrosion resistance, and lightweight properties, ideal for platforms, walkways, and drainage systems.

Q: What are the advantages of swage locked grating over welded grating?

A: Swage locked grating eliminates welding, reducing material stress and corrosion risks. Its mechanically locked joints provide consistent strength, while aluminum’s natural rust resistance ensures longevity in harsh environments.

Q: Where is aluminum swage locked grating commonly used?

A: It is widely used in chemical plants, offshore platforms, wastewater treatment facilities, and bridges. Its non-sparking and slip-resistant properties make it safe for industrial and marine applications.

Q: How to choose reliable aluminum grating manufacturers?

A: Look for manufacturers with certifications (e.g., ISO), custom fabrication capabilities, and proven industry experience. Check reviews and request material test reports to ensure quality compliance.

Q: Can swage locked grating be customized for specific projects?

A: Yes, reputable manufacturers offer customization in bar spacing, panel size, and surface treatments. This ensures the grating meets load requirements and environmental conditions of the application.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

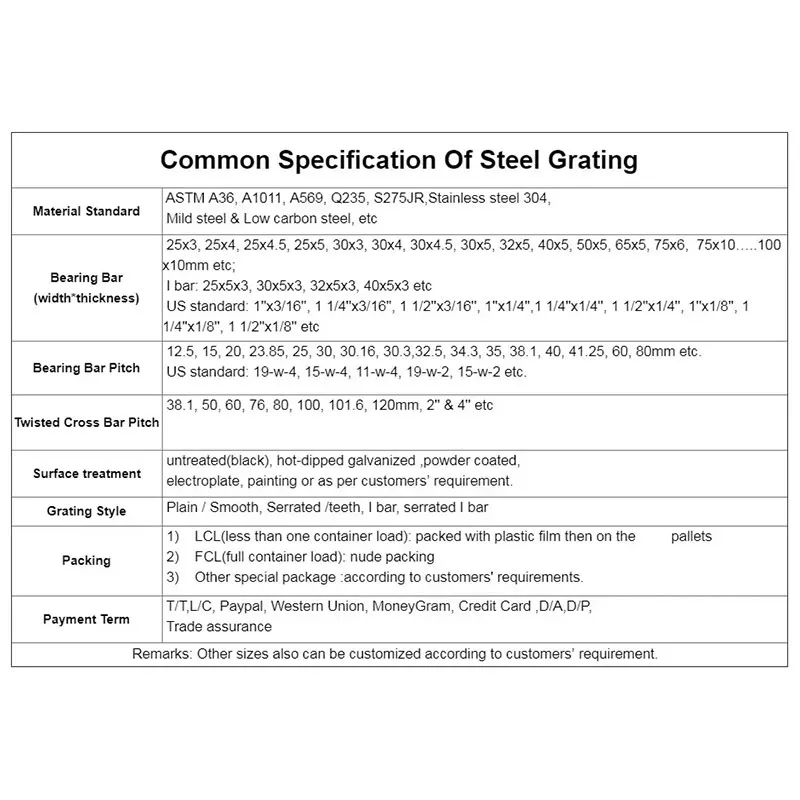

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA