Feb . 02, 2025 03:25 Back to list

aluminium corner bead

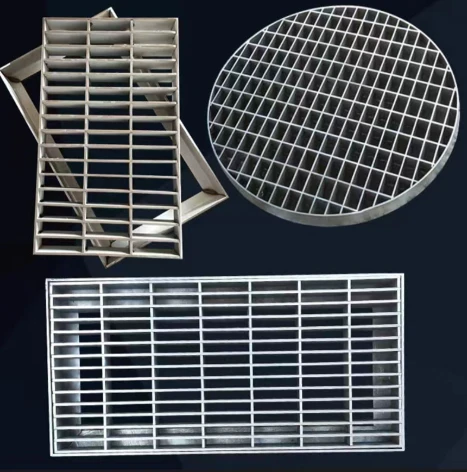

Industry experts often recommend aluminium over other materials like steel because of this balance of benefits. While steel may offer superior strength, aluminium’s resistance to environmental oxidation provides a practical edge in scenarios where weight-saving and low maintenance are key priorities. Aluminium floor grating is not only practical but also aligns with sustainability goals prevalent in today’s project specifications, given its recyclability and the minimal energy required for its production. In terms of safety, aluminium floor grating excels with its non-slip surface, an essential feature for ensuring safety in industrial and commercial environments. This characteristic helps prevent accidents in workplaces that are prone to wet or oily conditions. The ability to provide a safe walking surface without the need for additional treatments or coatings is another reason why industry standards and safety regulations often endorse the use of aluminium gratings. From an authoritative perspective, organisations that utilise aluminium floor grating frequently attest to its reliability and performance. These testimonials are backed by years of industry trust in aluminium as a robust and dependable material. As projects become increasingly sophisticated, the need for materials that provide exceptional performance without compromising on efficiency and sustainability becomes paramount. Aluminium floor grating meets these demands, delivering results that align with both structural needs and contemporary sustainability practices. In conclusion, the adoption of aluminium floor grating is a strategic decision informed by its numerous benefits and proven track record. Its capability to deliver on strength, adaptability, and longevity make it an invaluable resource in any engineering arsenal. As industries continue to evolve, the reliance on such materials will undoubtedly increase, making aluminium floor grating not just a choice, but a necessity for forward-thinking projects.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA