Mar . 06, 2025 17:38 Back to list

a142 reinforcing mesh

Trust in a142 reinforcing mesh is further established through its adherence to rigorous industry standards. It complies with BS44832005, among other international norms, guaranteeing its performance in emerging construction projects worldwide. This compliance, verified by certifications from leading industry bodies, assures project managers and contractors of the product's capability to meet anticipated performance and safety benchmarks. Furthermore, documentation and case studies highlight the long-term benefits of using a142 reinforcing mesh. Structures that incorporate this mesh report significantly lower maintenance costs over their lifespans, attributed to its ability to prevent cracking and structural deformities typically caused by environmental factors like temperature fluctuations or deliberate pressure from usage or external forces. Moreover, a142 reinforcing mesh’s adaptability helps optimize resource utilization. By customizing mesh dimensions based on specific project needs, waste is minimized, and efficiency is maximized, aligning with sustainable practices increasingly prioritized within the industry. By reducing surplus material usage, contractors not only economize on costs but contribute positively to environmental preservation efforts. Feedback from industry veterans emphasizes streamlined procurement processes, with suppliers providing detailed guidance on the integration of a142 meshes within various project scopes. Suppliers often offer simulation data that predicts how these meshes will perform under diverse conditions, allowing for meticulous planning and risk mitigation long before any actual groundwork commences. In conclusion, the a142 reinforcing mesh has established itself as an indispensable component within construction engineering. Its combination of practical benefits, regulatory compliance, and environmental sustainability ensures it remains a trusted choice across the industry. As architectural demands and environmental challenges continue to evolve, solutions like the a142 mesh that offer reliability and resilience will remain at the forefront of construction methodologies, embodying the principles of modern engineering and responsible building practices.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

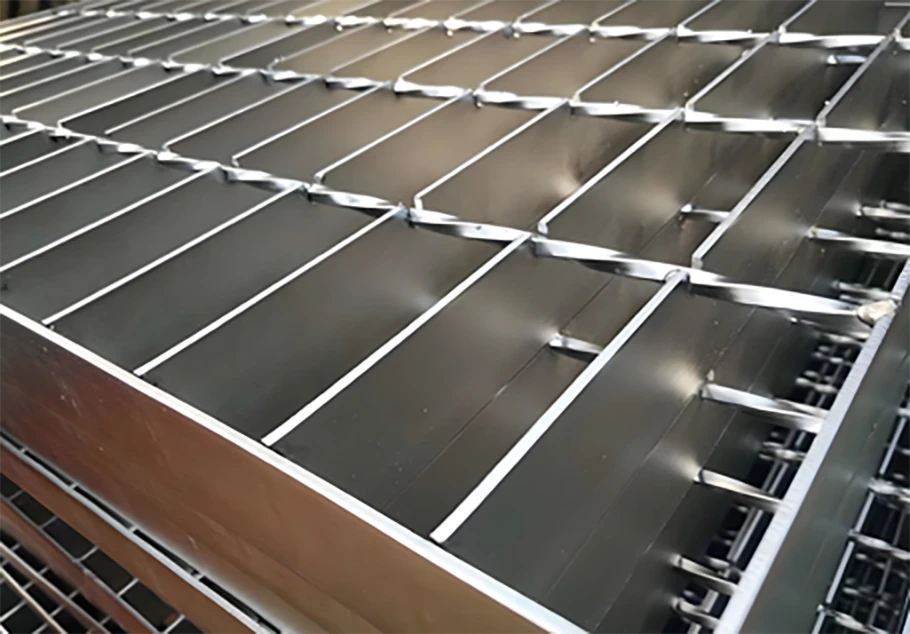

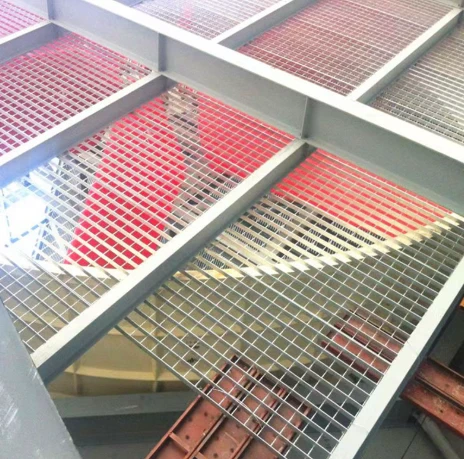

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA