Feb . 10, 2025 11:37 Back to list

pvc angle bead

Once securely attached, the next phase involves applying joint compound over the bead. This creates a smooth transition between the drywall and the bead, concealing any joints and fastening elements. Multiple layers of compound, accompanied by sanding between coats, are necessary to achieve a flush and seamless surface. The final outcome not only amplifies the aesthetic appeal of the room but also fortifies the corner significantly. The advantages of using 90 degree angle beads extend beyond mere aesthetics and durability. By securing these critical joints, the structural integrity of the building is preserved, reducing the occurrence of drywall cracking and subsequent repair costs. This proactive approach saves time and resources in the long run, making it a wise investment for both residential and commercial projects. In terms of innovation, the industry has witnessed a significant advancement in angle bead design. Modern beads now incorporate perforated flanges, which allow the joint compound to bond more effectively, minimizing cracking and improving bond strength. Additionally, some products are now equipped with a drywall mesh attached to the bead, facilitating a stronger hold and smoother finish. For environmental-conscious builders and DIY enthusiasts, sustainable options are available. Recyclable materials are increasingly used in the production of angle beads, aligning with green building practices. These sustainable products provide all the benefits of traditional beads while reducing the environmental footprint of construction activities. In conclusion, the 90 degree angle bead is an indispensable tool in contemporary construction, balancing functionality with aesthetic excellence. Its application requires a combination of skill and precision, underscoring the importance of choosing the right type and size for each project. By enhancing corner durability and finish quality, these beads not only improve the structural integrity of buildings but also contribute to their visual appeal, demonstrating their essential role in modern design and construction.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

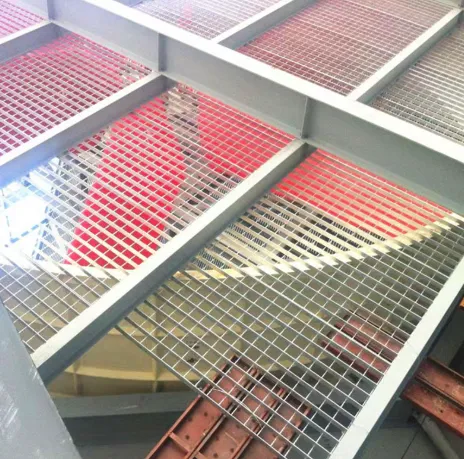

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA