Feb . 20, 2025 11:36 Back to list

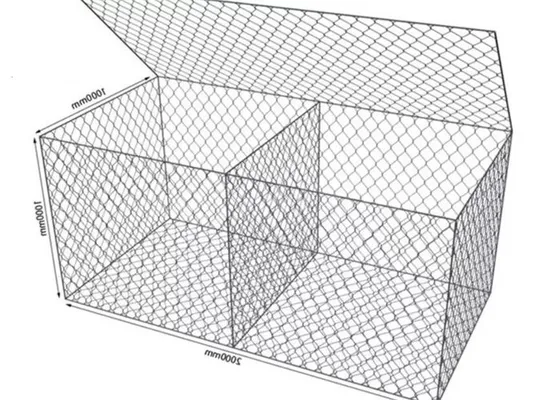

4x4 galvanized wire panels

The galvanization process that these wire panels undergo is not merely a routine procedure; it's a specialized practice that requires precision and expertise. Professionals understand that proper galvanization not only enhances longevity but is critical in maintaining the structural integrity of the panel when exposed to harsh conditions. When selecting 4x4 galvanized wire panels, consumers are urged to trust suppliers with a proven track record. Reputable manufacturers adhere to the highest standards of production and quality control, guaranteeing that each panel meets specific strength and safety criteria. In doing so, they offer assurance to the customer, reinforcing the trust placed in their products. As the modern world urges industries to adopt sustainable practices, galvanized wire panels offer an additional advantage. They are recyclable, thus aligning with global efforts towards environmental conservation. This environmentally friendly aspect adds to their appeal, ensuring that they remain a preferred choice for industries striving to minimize their ecological footprint. Investment in these panels is an investment in quality, reliability, and sustainability. Across various sectors, they continue to prove their worth, bringing peace of mind to users who require resources they can depend on. A testament to their utility, 4x4 galvanized wire panels remain a staple in construction and design, appreciated for their myriad attributes that serve both practical and aesthetic functions. In conclusion, 4x4 galvanized wire panels are more than just construction elements. They embody a perfect blend of strength, versatility, and durability, crafted through expert processes that guarantee their steadfast performance. Whether used to house livestock, support plant growth, or organize industrial spaces, they stand out as a testament to human ingenuity and the enduring quest for reliable and adaptable solutions in a complex world.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA