Jan . 19, 2025 00:59 Back to list

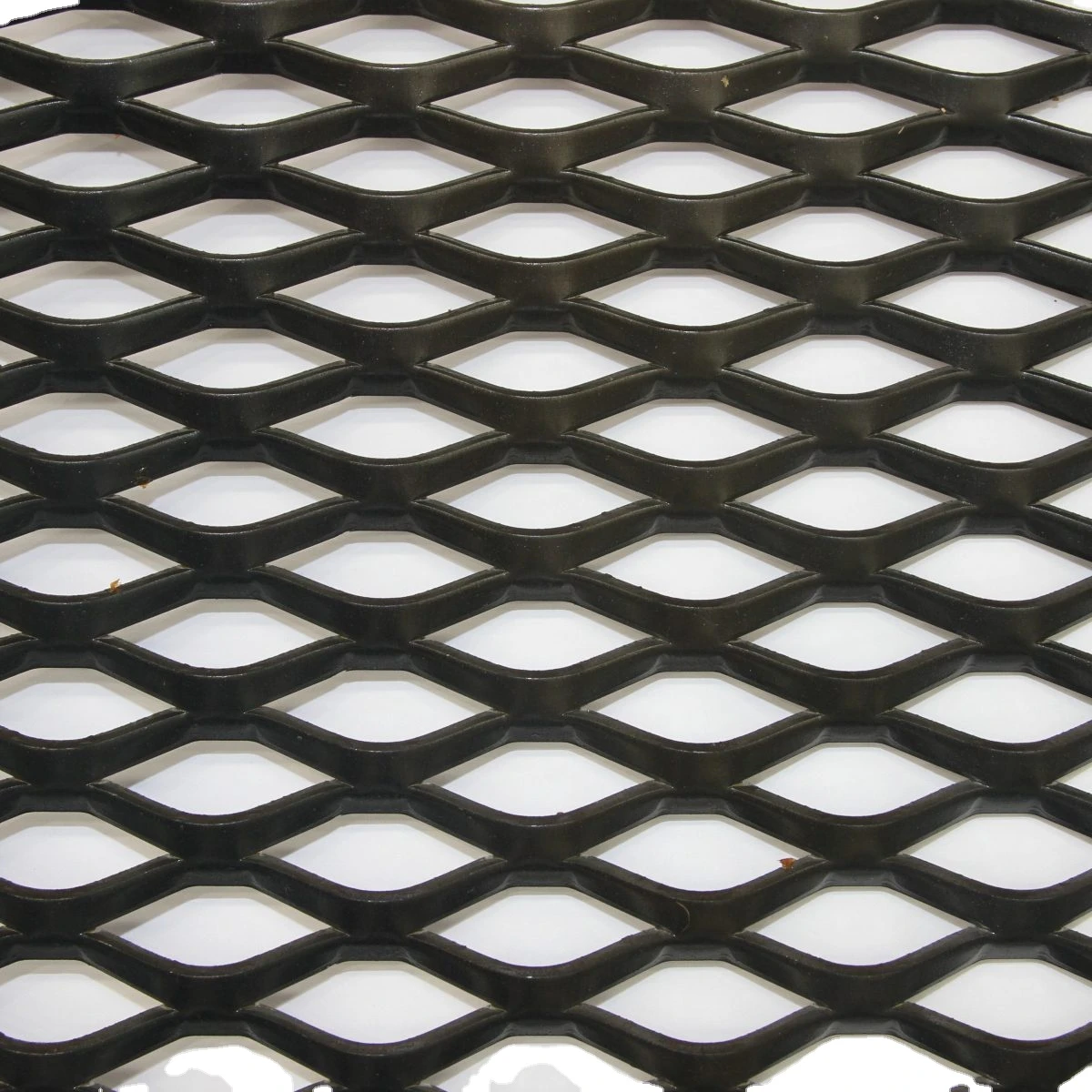

19 4 grating

Material selection also plays a critical role in the grating's performance. Common materials include stainless steel, carbon steel, and aluminum, each offering specific benefits. Stainless steel grating is prized for its corrosion resistance, making it ideal for marine and chemical environments. Carbon steel provides strength and affordability, while aluminum is preferred for its lightweight properties and anodized finish. Authoritativeness in the Industry Leading manufacturers of 19 4 grating are committed to upholding superior standards through rigorous quality control measures. Certifications from prominent industry organizations serve as a testament to the product's efficacy and reliability. These certifications ensure that every piece of grating meets the established criteria for safety, performance, and environmental impact. Offering detailed installation guides and ongoing technical support, these manufacturers establish themselves as authoritative voices in the field. Their commitment to innovation ensures that their grating solutions evolve to meet emerging industry trends and regulatory changes. Building Trust with Reliable Products Selecting the right grating solution is crucial for any project, and 19 4 grating consistently excels in instilling confidence among industry professionals. Through extensive testing and user feedback, its ability to maintain structural integrity under duress is well-documented, inspiring trust in its capabilities. Companies offering 19 4 grating frequently provide comprehensive warranties, reflecting their confidence in the longevity and durability of their products. Customer testimonials often highlight the reliability and performance of the grating in real-world scenarios, reinforcing its status as a trusted choice. In summary, 19 4 grating stands as a paragon of innovation in industrial flooring and structural applications. Its combination of strength, versatility, and compliance with industry standards positions it as a solution of choice for professionals seeking dependable grating options. As you navigate your next project, consider the advantages of 19 4 grating, and experience firsthand the blend of engineering prowess and practical functionality it offers.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA