Oct . 18, 2025 15:45 Back to list

Wire Mesh Conveyor Belts | Durable, Heat-Resistant, Custom

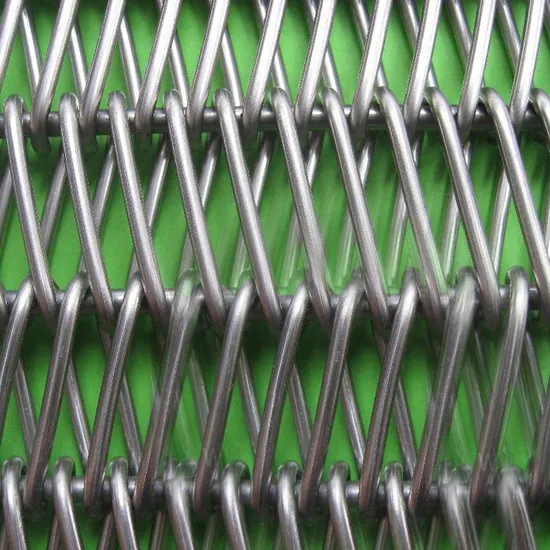

201/304/316L/310S Stainless Steel Metal Wire Mesh Conveyor Belts: Notes From the Floor

If you spend time around heat-treat furnaces or spiral freezers, you develop strong opinions about belts. Early on, I learned that wire mesh conveyor belts don’t just carry product—they dictate uptime, sanitation labor, and even energy use. Our subject today comes out of Shijiazhuang, China (B1213 GLOBAL CENTER, No.226 Zhonghua North Street), and it’s a stainless family that plants keep re-ordering, which says something.

What’s moving the market

To be honest, three threads are dominant: heat and hygiene, smarter maintenance, and sustainability. High-nickel 310S alloys for ovens up to ≈1100°C, smoother finishes for faster CIP, and sensors that catch tracking drift before it snaps a shaft. Many customers say they switched to wire mesh conveyor belts mainly to reduce cleaning time—surprisingly, that’s often a bigger win than heat resistance.

Technical snapshot

| Parameter | Typical Range / Note |

|---|---|

| Alloys | 201, 304/304L, 316/316L, 310/310S (food lines favor 304/316L; furnaces pick 310S) |

| Wire dia. | 0.6–3.0 mm (≈0.024–0.118 in) |

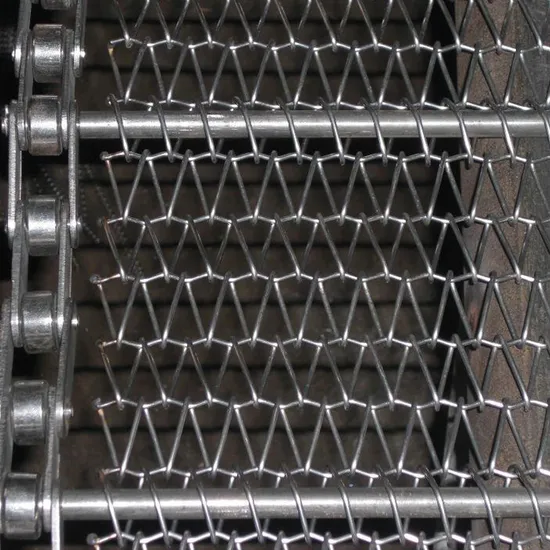

| Pitch / opening | 3–30 mm; open area ≈40–85% (real-world use may vary) |

| Belt width | 100–3000 mm custom |

| Temp rating | Up to ≈1100°C (310S); ≈600–800°C for 304/316L |

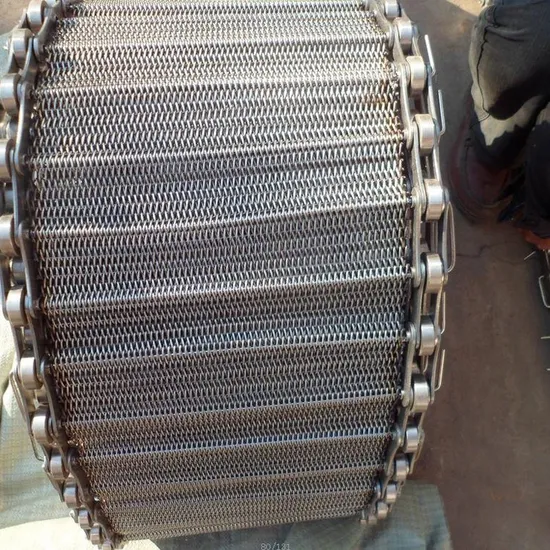

| Edges / drive | Welded/clinched/laddered; friction, sprocket, or chain-driven |

| Finish | Pickled & passivated; Ra ≈0.8–1.6 μm options |

| Standards | ASTM A580 (wire), ISO 9044 (wire cloth), EN 10204 3.1 MTC, FDA Food Code food-contact suitability |

Process flow and QC

Materials: draw-wire per ASTM A580, alloy-verified by PMI. Methods: balanced weave, compound balanced, and flat-flex patterns; weld or clinch edges; chain/rod integration for driven belts. Heat treatment for stress relief, then pickling and ASTM A967-style passivation. Tests: tensile (ASTM A370 methods), dimensional tolerance ±0.5%, warp/wear alignment, salt spray (ASTM B117) where relevant, and tracking runout (

Where they earn their keep

- Bakery ovens, proofer transfers, spiral coolers

- IQF freezing tunnels and blanchers in vegetables/seafood

- Glass annealing, powder coating cure lines, quench tanks

- Electronics sintering, brazing, debinding

- Washing, degreasing, and drip-dry conveyors

Advantages I see repeatedly: predictable tracking, easy spray-through cleaning, corrosion resistance, and a fair price-to-life ratio. The openness improves airflow—often a quiet energy saver. With wire mesh conveyor belts, airflow is half the story.

Vendor snapshot (real-world, approximate)

| Vendor | Alloys | Max Temp | Lead Time | Certs | After-sales | Price Index |

|---|---|---|---|---|---|---|

| Chengsen (China) | 201/304/316L/310S | ≈1100°C | 2–4 weeks | ISO 9001, EN 10204 3.1 | On-site/remote support | $ (cost-effective) |

| EU Brand A | 304/316L/314 | ≈1000°C | 4–8 weeks | ISO, CE | Regional distributors | $$$ |

| US Integrator B | 304/316L/310S | ≈1100°C | 3–6 weeks | UL (systems), ISO | Full line integration | $$ |

Customization and a quick case

Customization checklist: width, length, wire diameter, pitch, edge type, side guards/flights, drive (sprocket/chain), and target radius for spirals. It seems basic, but specifying cleaning chemistry up front avoids trouble later.

Case: a mid-size snack bakery swapped legacy belting for 316L balanced-weave wire mesh conveyor belts. Result after 8 months: throughput +12%, sanitation time −30%, belt life projected at 2.8 years. Internal friction tests showed coefficient drop from 0.18 to 0.12 after passivation—small number, noticeable energy delta.

Final notes

If your line runs hot, wet, or both, this family of stainless belts is a pragmatic pick. I guess the selling point isn’t drama—it’s fewer surprises between PMs.

References

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA