Oct . 17, 2025 12:25 Back to list

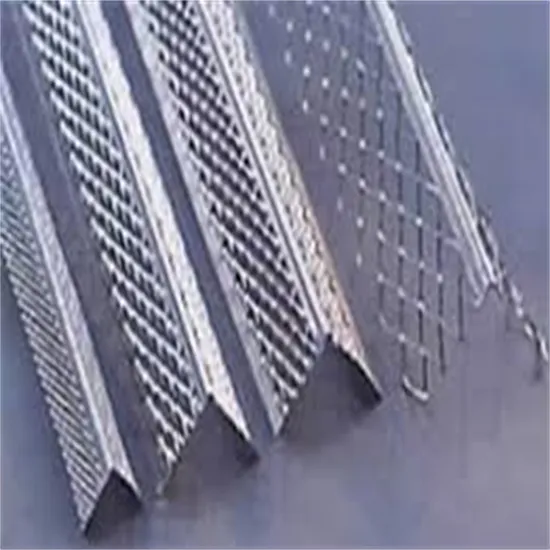

Galvanised Steel Stop Bead | Rust-Resistant, Clean Finish

Field Notes: Why a galvanised steel stop bead still rules the edge

Walk any active site and you’ll see it: corners, reveals, and render terminations that look sharp today and — ideally — still sharp in five years. That’s the quiet job of the humble stop bead. I’ve tested more than a few, and to be honest, the difference between “fine” and “future-proof” often comes down to coating, gauge, and how cleanly it beds into plaster.

What’s trending on site

Two clear shifts: first, contractors are standardizing on Z275 (or higher) coatings for external work; second, procurement teams want vendor paperwork — CE/UKCA, mill certs, and salt-spray results — not just a glossy spec sheet. It seems that value now equals data-backed durability, not just price-per-length.

Product snapshot

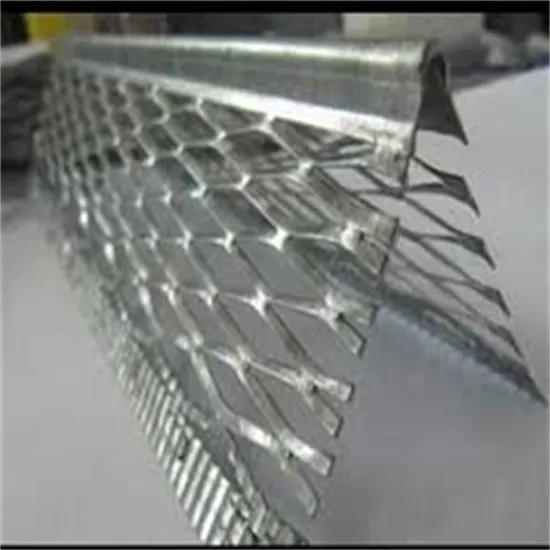

Product: Galvanized Steel Plaster Stop Bead Drywall External Corner Bead Protect Mesh (origin: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA). Chengsen also offers aluminium and stainless options — expanded or perforated — for special environments. In fact, many customers say the expanded web beds faster in hand-applied render.

| Parameter | Typical spec (≈) | Notes |

|---|---|---|

| Base metal | GI steel per EN 10346 / ASTM A653 | Continuous hot-dip |

| Coating mass | Z275 (≈ 275 g/m²) | Z200–Z350 available |

| Thickness | 0.30–0.45 mm | Project-dependent |

| Lengths | 2.4 m, 2.7 m, 3.0 m | Custom cuts possible |

| Perforation/mesh | Expanded or perforated | Better key and bond |

| Service life | ≈ 20–30 yrs interior; 10–20 exterior | Real-world use may vary by environment |

How it’s made (quick process flow)

- Material selection: coil steel to EN 10346 / ASTM A653, selected for coating class.

- Forming: roll-forming for arris; simultaneous perforation/expansion for plaster key.

- Cutting and deburring: clean edges to reduce shadow lines.

- QC and testing: coating mass checks, adhesion, dimensional tolerance, and visual.

- Packing: straightness protected; moisture-safe wrap (sounds minor, saves callbacks).

Standards we see referenced: ASTM C1063 for lath/plaster installation, EN 13658 for metal lath and beads, and ISO 9227 for comparative salt-spray benchmarks. Honestly, the paperwork matters as much as the bead.

Where it excels

Drywall returns, window/door reveals, base-of-render terminations, and external corners in residential, retail fit-outs, healthcare corridors (lots of trolley impacts), and education builds. A galvanised steel stop bead gives a crisp line and a sacrificial edge — the plaster fails before the corner does.

Case in point: a coastal hotel refurb switched from uncoated angle to a galvanised steel stop bead with Z275. Snag list dropped by 60% in year one; repaint cycles stretched by roughly two seasons. Another GC told me, “It just beds cleaner — less feathering, less rework.”

Vendor snapshot (what buyers compare)

| Vendor | Coating | Certs | MOQ | Lead time | Notes |

|---|---|---|---|---|---|

| Chengsenmesh (Shijiazhuang) | Z200–Z350 | ISO 9001, EN/ASTM refs | ≈ 5,000–10,000 pcs | 2–4 weeks | Custom perforation, OEM packs |

| Importer A (generic) | Z140–Z200 | Basic CoC | ≈ 2,000 pcs | 1–2 weeks | Budget option; indoor only |

| Importer B (premium) | Z275+ | EN 13658 mention | ≈ 3,000 pcs | 3–5 weeks | Higher price; strong docs |

Customization and QA

- Profiles: stop, corner, render reveal; special noses on request.

- Materials: GI standard; aluminium or stainless for aggressive zones.

- Testing: coating mass (magnetic gauge), bend/adhesion, ISO 9227 salt spray benchmarks, straightness checks.

Bottom line: for most mixed-use projects, a galvanised steel stop bead with Z275 coating and clean expansion pattern is the sweet spot — durable, economical, and compliant. If you’re coastal or industrial, consider stainless or at least step up the coating. I guess it’s not glamorous, but it’s the edge your finishes deserve.

Authoritative sources

- ASTM C1063 – Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster.

- EN 13658-2 – Metal lath and beads for internal plastering.

- ASTM A653 / EN 10346 – Steel sheet, zinc-coated (galvanized) by hot-dip process.

- ISO 9227 – Corrosion tests in artificial atmospheres (salt spray tests).

- BS EN 13914-1 – Design, preparation and application of external rendering.

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA