Oct . 19, 2025 15:25 Back to list

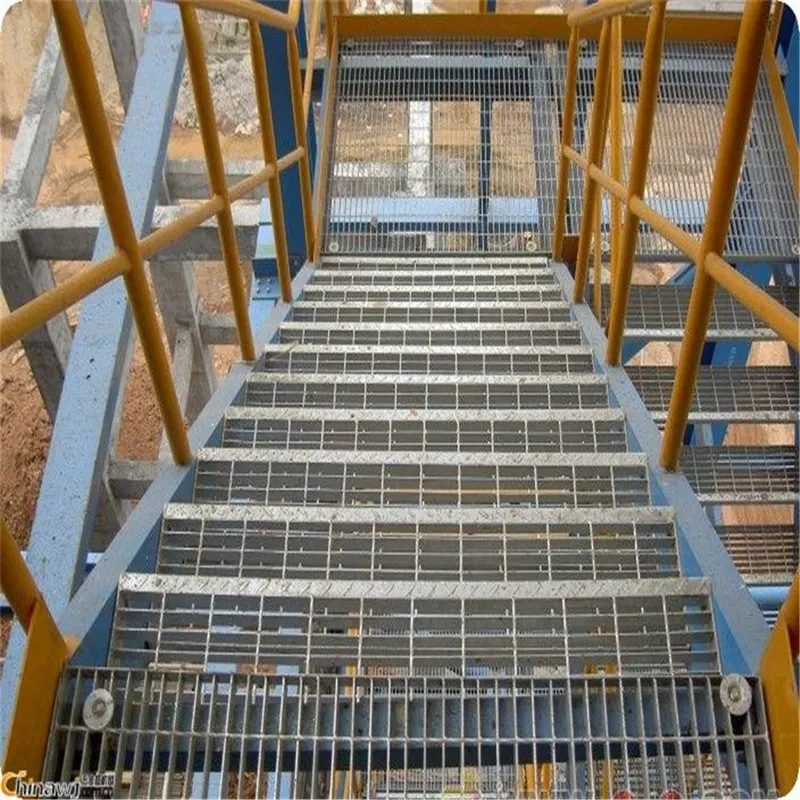

Hot Dip Galvanized Composite Steel Grating Treads Non-Slip

If you work around industrial stairs long enough, you learn two things: slip resistance is non-negotiable, and a good galvanizing job is worth its weight in downtime avoided. That’s why I’ve been following Hot Dip Galvanized Composite Steel Grating Grilles Stair Steps And Stair Treads closely—particularly the composite styles with checkered plate tops that are showing up in plants from Shanghai to Savannah.

Origin note: these are produced out of B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA. The company pitches them as “Description Introduction to stair step grating,” but, to be honest, the specs do much more of the talking.

Industry trends I’m seeing

- Shift to composite grating (grating + checkered plate) where dropped tools or small parts are a risk.

- Stricter safety audits: more serrated nosings, higher BPN slip ratings, and documented zinc thickness.

- Modular, bolt-on treads for faster shutdown work—no hot work permits, minimal welding onsite.

Process flow (how these are actually made)

Materials: typically Q235/Q345 carbon steel bearing bars with twisted square cross bars. Composite versions receive a 3–4.5 mm checkered plate welded to the grating panel. Fabrication is resistance forge-welded, then edge-banded, with toe plates and pre-drilled end plates for bolting. The big step is hot dip galvanizing to ISO 1461/ASTM A123: degrease → pickle → flux → zinc bath (≈450°C) → quench/passivate → thickness check. Typical QC: zinc thickness (70–100 μm), adhesion, visual continuity, slip tests on serrated nosing, and dimensional tolerances. Real-world service life? In C3 environments around 25–35 years; C4 coastal/chemical areas 15–25 years, depending on exposure and maintenance.

Quick spec sheet

| Bearing bar size | 25×3, 30×3, 32×5, 40×5 mm (others on request) |

| Bar pitch / Cross pitch | 30/100 mm, 30/50 mm, 40/100 mm (≈, project dependent) |

| Composite plate | 3–4.5 mm checkered plate, stitch-welded to grating |

| Finish | Hot dip galvanized per ISO 1461 / ASTM A123 |

| Zinc coating | ≈70–100 μm average (real-world use may vary) |

| Nosing options | Serrated steel, checkered plate, or abrasive insert |

| Tread width/length | 180–320 mm width; 600–1200 mm length typical |

| Fixing | Bolted end plates with Ø10–12 mm holes; clip sets available |

| Load guidance | Designed to meet OSHA/EN industrial stair service loads |

Where they get used (and why)

- Chemical, wastewater, power plants: drainage plus anti-slip under wet process conditions.

- Food & beverage: composite tops stop small objects falling through; easy hose-down.

- Oil & gas, marine: thicker zinc combats salt spray; serration helps in oily mist.

- Public access catwalks, data centers MEP: clean look, predictable stiffness-to-weight.

Many customers say the Hot Dip Galvanized Composite Steel Grating Grilles Stair Steps And Stair Treads feel “planted” underfoot—especially with serrated nosing. In one beverage plant audit, pendulum slip resistance on wet sugary residue still measured BPN 55–60 (lab guide: >45 is generally acceptable for wet areas).

Vendor comparison (indicative)

| Vendor | Zinc thickness (avg) | Docs & certs | Lead time | Notes |

|---|---|---|---|---|

| Chengsen (origin Shijiazhuang) | ≈80–100 μm | ISO 9001, mill certs, ISO 1461 report | 3–5 weeks | Strong on composite customization |

| Generic Importer | ≈60–80 μm | Basic CoC only | 5–7 weeks | Lower upfront cost |

| Local Fabricator | Varies (paint or HDG) | Project-specific | 1–3 weeks | Fast turn, limited composite options |

Customization and testing

Options include serrated vs. plain bearing bars, open vs. composite top, galvanized thickness targets, anti-slip nosing styles, and pre-punched bolt patterns. Typical tests: zinc thickness gauge per ISO 1461, salt spray (ASTM B117) when specified, load/deflection to site standard, and slip testing (British Pendulum) on wet/oily surfaces. One recent lot report I read showed an 85 μm average zinc layer, minimal runs/drips, and weld integrity passing bend tests—nothing flashy, just solid.

Two fast case notes

- Coastal bulk terminal: swapped aging checker-plate treads for Hot Dip Galvanized Composite Steel Grating Grilles Stair Steps And Stair Treads. After 18 months in C4, zinc loss rates looked in line with ISO 9223 tables; maintenance crew noted better drainage and fewer slip complaints.

- Craft beverage facility: composite treads kept bottle caps from dropping through; QA loved the hose-down cleanability. Installers appreciated the pre-drilled end plates—no sparks, no drama.

Bottom line: if you need durable, audit-friendly stair treads that balance weight, drainage, and safety, these Hot Dip Galvanized Composite Steel Grating Grilles Stair Steps And Stair Treads are a pragmatic pick. Not glamorous—just the kind that keep people on their feet and projects on schedule.

Authoritative citations

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- OSHA 29 CFR 1910 Subpart D: Walking-Working Surfaces (industrial stairs and treads requirements).

- ISO 9223: Corrosion of metals and alloys — Corrosivity of atmospheres — Classification, determination and estimation.

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA