Sep . 02, 2025 09:31 Back to list

Why Black Corner Bead Dominates Modern Construction

In the intricate dance of drywall installation, where precision meets aesthetics, one component often operates in the background yet plays a starring role in the final act: the corner bead. This unassuming profile, typically crafted from durable corner bead metal, shields the most vulnerable points of our walls – the corners – from impact and wear. But step onto any contemporary construction site or browse modern design magazines, and you'll notice a distinct shift: the rising, undeniable prominence of the black corner bead. What's driving this surge in popularity? Why has this specific finish moved from niche preference to mainstream essential? Let's delve into the compelling reasons behind the black corner bead phenomenon and explore its impact on the building industry.

Understanding the Corner Bead Metal Foundation

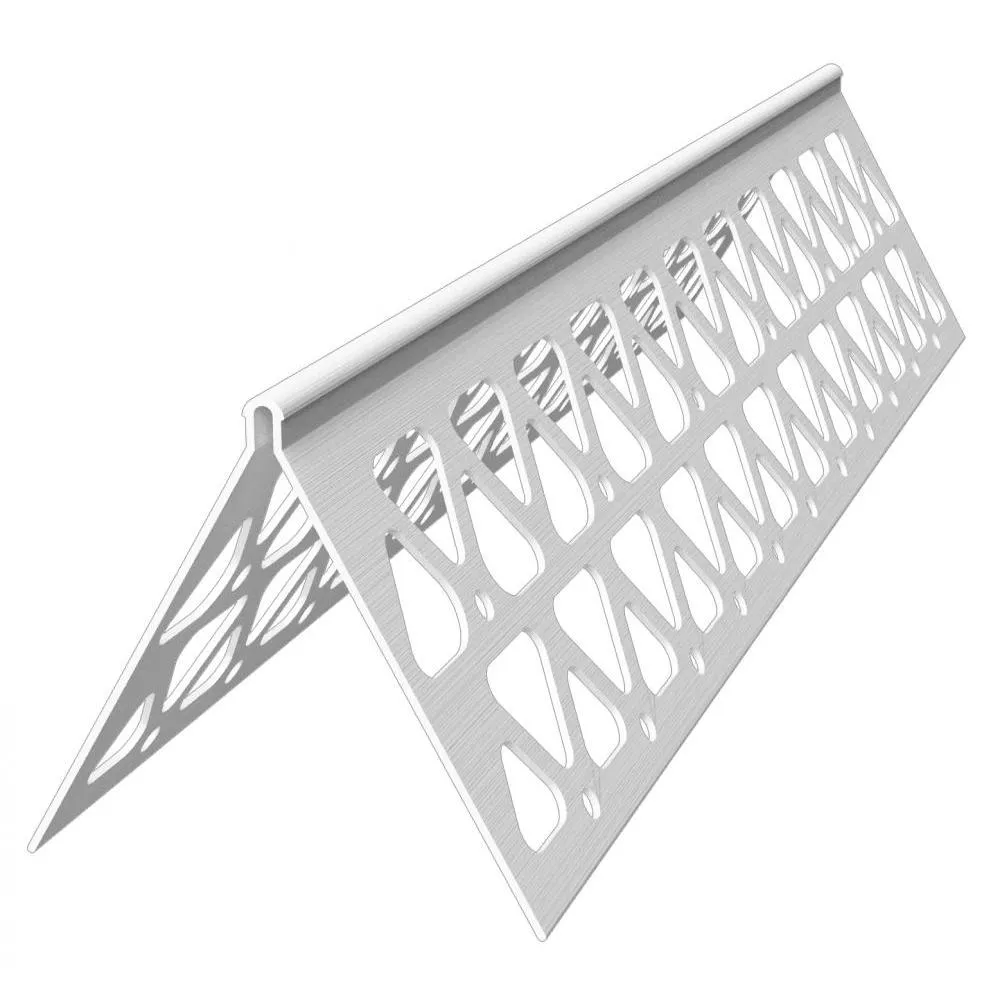

Before appreciating the black corner bead, it's vital to grasp the fundamentals of the corner bead itself. Essentially, a corner bead is a protective trim applied to the external corners of drywall (plasterboard) installations. Its primary functions are:

Protection: Drywall corners are inherently fragile. A corner bead acts as an armor, shielding the vulnerable drywall paper and gypsum core from knocks, bumps, and general wear and tear caused by furniture, moving objects, or everyday activity.

Defining a Crisp Edge: It provides a rigid, straight guide for applying joint compound (mud), ensuring a sharp, clean, and geometrically precise 90-degree angle. Without it, corners tend to be rounded, uneven, and prone to chipping.

Reinforcement: The corner bead metal adds significant structural integrity to the corner, preventing cracking or crumbling over time, especially in high-traffic areas.

Traditionally, corner bead metal was galvanized steel – zinc-coated to resist rust. While effective, the bright silver finish posed a challenge during the finishing process. If the joint compound layer was too thin or sanded too aggressively, the shiny metal could show through, creating a visible "ghost line" or "shine-through" that marred the painted surface. This often necessitated extra layers of mud and meticulous sanding, increasing labor time and cost. Vinyl corner beads emerged as an alternative, eliminating the shine-through issue but sometimes lacking the rigidity and impact resistance of metal. Enter the black corner bead, offering a superior solution that addresses the limitations of its predecessors.

The Allure of Black Corner Bead: Aesthetics Meets Function

The rise of the black corner bead isn't merely a stylistic whim; it's a convergence of practical advantages and sophisticated design sensibilities. Here’s why it’s becoming the go-to choice:

Eliminating Ghost Lines & Shine-Through: This is the black corner bead's killer feature. The dark, matte black finish absorbs light instead of reflecting it. Even if the joint compound layer is slightly thin or sanding inadvertently exposes the bead, the black color blends inconspicuously with the shadow naturally present in a corner. This dramatically reduces the risk of visible lines after painting, leading to a flawless, professional finish with less effort and material.

Enhanced Durability & Rust Resistance: High-quality black corner bead metal typically features a robust, baked-on polyester powder coating or a specialized black phosphate coating over galvanized steel. This coating provides an extra layer of protection against corrosion, making it ideal for humid environments like bathrooms, kitchens, or coastal areas where standard galvanized beads might eventually show signs of rust. The coating also adds resistance to scratches during handling and installation.

Superior Adhesion for Joint Compound: The textured surface of many powder-coated black corner bead profiles offers a superior mechanical "key" for the joint compound. This enhanced adhesion minimizes the risk of the mud cracking or delaminating from the bead over time, ensuring a long-lasting, seamless corner.

Modern Aesthetic Versatility: Beyond pure function, the black corner bead aligns perfectly with contemporary design trends. It seamlessly complements dark color schemes, industrial aesthetics (exposed elements), and minimalist designs. Even when painted over, the knowledge that the bead underneath won't cause visual issues provides peace of mind. For designers specifying shadow gaps or reveals, a black corner bead can sometimes be left intentionally exposed as a deliberate design feature, adding a crisp, linear detail.

Professional Standard: Due to its performance advantages, the black corner bead is increasingly specified by architects and demanded by high-end builders and discerning homeowners. Using it signals an attention to detail and a commitment to a superior, long-lasting finish.

Manufacturing Excellence: The Chengsen Advantage in Corner Bead Metal

The performance of any corner bead, especially a black corner bead, hinges critically on the quality of the raw corner bead metal and the precision of its manufacturing. This is where expertise honed over decades becomes paramount. Shijiazhuang Chengsen Trading Co., Ltd., with over 25 years of specialized experience in steel fabrication, brings this essential expertise to the corner bead market.

Chengsen's foundation is built on the uncompromising principle that "product quality is the first." This philosophy permeates every stage of production, from sourcing high-grade steel to the final coating application for the black corner bead. Their stringent quality control protocols, aligned with rigorous international standards like China's YB/T4001.1-2007, British BS4592-1-1995, and American ANSI/NAAMM (MBG531-88), guarantee that every length of corner bead metal meets exacting specifications for dimensional accuracy, strength, and coating integrity.

For the black corner bead, the coating process is particularly crucial. Chengsen employs advanced coating technologies – whether it's a durable black phosphate treatment or a resilient polyester powder coat – ensuring the finish is not just aesthetically uniform but also provides exceptional corrosion resistance and adhesion properties. The black finish is consistent, matte, and designed specifically to prevent the shine-through issues that plague traditional galvanized beads.

Furthermore, Chengsen's extensive experience as a global exporter (boasting 18 years and a remarkable 95% repeat order rate) means they understand the diverse demands of international markets. Their in-house team of skilled CAD designers allows them to respond effectively to specific requests, ensuring the corner bead metal profiles, including specialized black corner bead variants, perfectly suit project requirements. This commitment to quality, backed by a vast production capacity (evidenced by moving approximately 200,000 tons of steel products annually) and a focus on fast, reliable delivery, makes Chengsen a trusted partner for sourcing high-performance black corner bead products globally. Their 7-year Golden Supplier status is a testament to their consistent reliability and dedication to customer satisfaction through the business tenet of "quality first, customer first."

Versatility in Application: Where Black Corner Bead Shines

The black corner bead isn't limited to just standard residential drywall corners. Its unique properties make it exceptionally versatile across numerous applications:

High-Traffic Commercial Spaces: In offices, schools, hospitals, and retail environments where walls face constant bumping from carts, furniture, and foot traffic, the enhanced durability and impact resistance of quality black corner bead metal are invaluable. Its resistance to damage ensures corners stay sharp and intact for years.

Moisture-Prone Areas: Bathrooms, laundry rooms, commercial kitchens, and basements benefit immensely from the superior corrosion resistance of a properly coated black corner bead. It stands up to humidity and occasional moisture exposure far better than standard galvanized options.

Modern Architectural Details: Beyond standard 90-degree corners, black corner bead is used for:

Archways: Creating crisp, protected curves.

Bullnoses: Providing a smooth, rounded edge finish (using specialized bullnose beads, often available in black).

Reveals and Shadow Gaps: Intentionally creating linear recesses or gaps between wall panels or at ceiling lines. The black corner bead provides a clean, dark line that enhances the architectural effect. The bead itself can sometimes form the visible edge in these designs.

Exposed Beam Wraps: Protecting and finishing drywall wrapped around structural beams, where the black finish can complement an industrial look.

Renovation Projects: When repairing damaged corners, a black corner bead offers a reliable solution that integrates seamlessly with existing walls, minimizing the risk of future ghost lines appearing on the repair.

Exterior Applications (Specific Products): While standard interior black corner bead is for drywall, specialized, heavier-gauge PVC-coated or specific exterior-grade metal trim profiles (which can also be black) are used with exterior sheathing systems (like stucco or EIFS) for durable, protected corners.

The adaptability of the black corner bead, combined with its performance benefits, makes it a truly universal solution for achieving durable, flawless corners in virtually any setting.

Black Corner Bead: FAQs

What are the main advantages of black corner bead?

The black corner bead offers several key advantages over traditional galvanized metal beads. Primarily, its dark, matte finish eliminates ghost lines and shine-through, ensuring a flawless painted surface even with minimal joint compound. Secondly, the specialized coating (often powder coat or phosphate) provides superior corrosion resistance, making it ideal for humid or moisture-prone areas. Thirdly, the coating often enhances adhesion for joint compound, reducing the risk of cracking. Finally, it offers exceptional durability against impacts and scratches during installation and everyday use. These benefits translate to a higher quality, longer-lasting finish with potentially reduced labor costs.

Is black corner bead more durable than galvanized?

Yes, a high-quality black corner bead is generally more durable than a standard galvanized bead in several ways. The baked-on powder coating or specialized black finish provides an extra protective layer beyond the base galvanization. This makes it significantly more resistant to corrosion, especially crucial in bathrooms, kitchens, or coastal climates. The coating also offers enhanced scratch and abrasion resistance during handling, installation, and everyday impacts. While the underlying corner bead metal strength is similar, the protective finish of the black corner bead gives it a clear edge in long-term resilience and appearance maintenance.

Can black corner bead be used in bathrooms?

Absolutely! In fact, bathrooms are one of the ideal environments for black corner bead. Standard galvanized beads can eventually rust when exposed to the constant high humidity and potential moisture splashes in bathrooms. The superior corrosion resistance provided by the specialized coatings on black corner bead metal makes it perfectly suited for this challenging environment. It provides reliable, long-lasting protection for your vulnerable drywall corners, preventing unsightly rust stains and ensuring the integrity of the finish for years to come.

Does black corner bead require special installation?

No, installing black corner bead follows the same fundamental process as installing standard galvanized metal corner bead. It is typically nailed or screwed securely to the drywall studs at the corner, ensuring it is straight and true. Joint compound is then applied over the flanges of the bead and feathered out onto the drywall panels. The key difference is the significant advantage: because the black finish prevents shine-through, installers often find they can achieve a perfect finish with slightly less joint compound or with less concern about sanding down to the metal. No special tools or techniques beyond standard drywall finishing are required.

How do I know if the black corner bead meets quality standards?

Ensuring your black corner bead meets high-quality standards is crucial for performance. Look for suppliers who explicitly state compliance with recognized international standards such as ASTM (American Society for Testing and Materials), ANSI/NAAMM (for metal bar gratings, relevant to the base metal quality), or equivalent regional standards (like BS in the UK or YB in China). Reputable manufacturers, like those with decades of experience in steel fabrication and a focus on quality control at every stage, will readily provide this information. The coating should be uniform, strongly adhered, and free from defects. Choosing a supplier with a proven track record, high repeat customer rates, and certifications provides confidence in the corner bead metal's quality and performance.

The ascent of the black corner bead from a specialty item to a mainstream staple is no accident. It represents a significant evolution in drywall protection and finishing technology. By solving the persistent problem of ghost lines inherent in traditional galvanized corner bead metal, it delivers a consistently superior aesthetic result with greater efficiency. Its enhanced durability, particularly the robust corrosion resistance offered by high-quality coatings, extends the lifespan of corners in demanding environments, reducing maintenance and repair costs. The alignment with modern design trends, offering both concealed perfection and the option for exposed crisp detailing, further cements its relevance.

Manufacturing excellence is non-negotiable for this critical component. Companies like Shijiazhuang Chengsen Trading Co., Ltd., leveraging decades of specialized experience in high-grade steel fabrication and stringent adherence to international quality standards (YB/T4001.1-2007, BS4592-1-1995, ANSI/NAAMM MBG531-88), are instrumental in providing the reliable, high-performance black corner bead products the market demands. Their commitment to quality control, corrosion-resistant coatings, dimensional precision, and customer-centric service ensures that builders, contractors, and homeowners receive a product that truly performs.

Whether it's a high-end residential project, a bustling commercial space, a moisture-prone bathroom, or a renovation requiring a flawless repair, the black corner bead has proven its worth. It’s more than just a trend; it’s a smarter, more durable, and aesthetically versatile solution that has rightfully earned its place as the modern standard for protecting and perfecting the corners that define our spaces. As construction techniques and design preferences continue to evolve, the black corner bead stands ready, a testament to how thoughtful innovation in fundamental building components can elevate the entire built environment.

Latest News

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

-

Ferrotech Grating: Durable Solutions for Modern Industry

NewsNov.17,2025

-

Trusted Aluminum Grating Manufacturers | Durable & Light

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA