Sep . 08, 2025 11:37 Back to list

Reinforcing Concrete: Strong Types of Wire Mesh

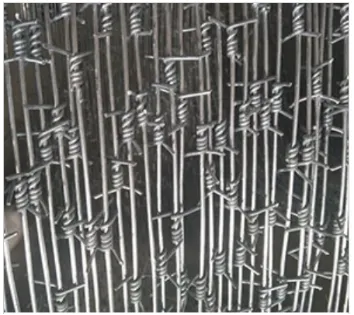

In the realm of construction, the strength and durability of concrete structures hinge on the quality of their reinforcement. Types of wire mesh designed for reinforcing concrete play a pivotal role in enhancing load-bearing capacity, preventing cracks, and extending the lifespan of buildings, bridges, and infrastructure. This article delves into the robust wire mesh series engineered for concrete reinforcement, how wire mesh custom solutions address unique project needs, and why investing in high-quality meshes is essential for long-lasting structural integrity.

Robust Materials in Types of Wire Mesh for Concrete Reinforcement

The foundation of strong concrete reinforcement lies in selecting the right types of wire mesh from proven wire mesh series. Mild steel mesh, a common choice, offers excellent tensile strength at a moderate cost, making it suitable for residential foundations, driveways, and slab flooring. Galvanized steel mesh, with its corrosion-resistant zinc coating, is ideal for environments where moisture could threaten longevity, such as basements, swimming pools, or coastal buildings. Stainless steel mesh, though premium, provides unmatched resistance to chloride-induced corrosion, making it indispensable for high-stakes projects like marine structures, highway bridges, or industrial facilities exposed to harsh chemicals.

Each material in the wire mesh series is manufactured to meet strict international standards, including China’s YB/T4001.1-2007 and American ANSI/NAAMM guidelines, ensuring consistent wire diameter, mesh spacing, and tensile strength. These meshes act as a skeleton within concrete, distributing stress evenly and reducing the risk of cracking under weight, temperature changes, or seismic activity.

Key Applications of Wire Mesh Series in Structural Reinforcement

Reinforcing wire mesh series are integral to a wide range of construction projects, providing both strength and versatility. In residential buildings, welded wire mesh reinforces concrete slabs, preventing cracks caused by settlement or heavy loads. For commercial structures, such as parking garages or warehouse floors, heavier-duty galvanized mesh enhances impact resistance and durability, even under constant vehicular traffic.

In infrastructure projects, stainless steel mesh plays a critical role in bridges and tunnels, where exposure to de-icing salts or moisture demands superior corrosion resistance. Precast concrete elements, like wall panels or drain covers, rely on precision-engineered meshes to maintain structural coherence during transportation and installation. Agricultural applications benefit from galvanized mesh as well, reinforcing concrete feedlots or drainage systems that endure constant moisture and mechanical stress.

Beyond traditional uses, these meshes support innovative designs, such as thin-shell concrete structures or decorative concrete panels, where strength must coexist with architectural creativity. The wire mesh series adapt to diverse project scales, from small home renovations to large-scale industrial complexes, proving their indispensability in modern construction.

Custom Solutions: Crafting Wire Mesh Custom for Specific Reinforcement Needs

No two construction projects are identical, and wire mesh custom solutions ensure that reinforcement meets exact structural requirements. Engineers may specify a bespoke mesh with larger wire gauges for high-load industrial floors or closer mesh spacing to prevent fine cracks in decorative concrete. Custom coatings, such as epoxy or polymer finishes, can enhance corrosion resistance in aggressive environments, while specialized welding techniques ensure uniform load distribution.

A curved concrete staircase might require a custom-bent stainless steel mesh to match its unique geometry, or a historic building restoration might need a mesh that replicates vintage reinforcement patterns while meeting modern strength standards. These solutions not only enhance structural performance but also streamline installation, reducing on-site adjustments and delays.

By combining material expertise with design flexibility, wire mesh custom ensures that every concrete structure—whether a skyscraper foundation or a backyard patio—benefits from reinforcement that’s as precise as it is powerful.

FAQ: Maximizing Strength and Durability with Reinforcing Wire Mesh Series

How Do Types of Wire Mesh Strengthen Concrete Structures?

Reinforcing types of wire mesh act as a tensile reinforcement, countering concrete’s natural weakness in handling pulling forces. They distribute stress across the concrete matrix, reducing the risk of cracking under load, temperature changes, or ground movement. This collaboration between mesh and concrete creates a composite material that’s far stronger than either component alone.

Which Wire Mesh Series Is Best for Corrosion-Prone Environments?

In areas with high moisture, salt, or chemical exposure, galvanized steel or stainless steel meshes from the wire mesh series are ideal. Galvanized mesh offers a cost-effective zinc barrier against rust, while stainless steel (especially grade 316) provides superior resistance to chloride-induced corrosion, making it suitable for marine, industrial, or northern climates with de-icing salts.

Can Wire Mesh Custom Solutions Enhance Structural Aesthetics?

Yes, custom meshes can be designed to complement architectural goals. For exposed concrete surfaces, such as concrete countertops or decorative walls, wire mesh custom with intricate patterns or stainless steel finishes can add visual texture without compromising strength. Engineers can also tailor mesh sizes and wire thickness to meet both aesthetic preferences and load-bearing requirements.

What Are the Long-Term Benefits of Investing in High-Quality Reinforcing Wire Mesh Series ?

Premium wire mesh series reduce the need for costly repairs or replacements by resisting corrosion, maintaining structural integrity, and minimizing crack formation. Over time, this translates to lower maintenance costs, extended service life for structures, and improved safety—especially critical for infrastructure projects where failure risks are high.

How to Ensure Proper Installation of Reinforcing Wire Mesh Series?

Proper placement is key: meshes should be centered within the concrete layer, supported by spacers to maintain consistent cover depth. Ensure mesh edges are securely tied or welded to prevent shifting during pouring. Following manufacturer guidelines and industry standards, such as proper overlap dimensions for mesh sections, will maximize reinforcement effectiveness and structural longevity.

Latest News

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

-

Ferrotech Grating: Durable Solutions for Modern Industry

NewsNov.17,2025

-

Trusted Aluminum Grating Manufacturers | Durable & Light

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA