Sep . 09, 2025 14:46 Back to list

How Aluminum Grate Mesh Revolutionizes Drainage Systems

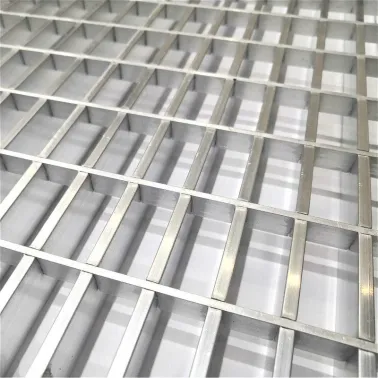

In the intricate dance of infrastructure, effective drainage is the silent partner ensuring everything flows smoothly. From bustling city streets and industrial complexes to serene walkways and rooftop gardens, managing water runoff is paramount to safety, longevity, and functionality. For decades, traditional materials like steel or concrete dominated drainage solutions. However, a superior contender has steadily risen to prominence, offering unparalleled benefits: aluminum grate mesh. This innovative material, particularly in forms like aluminum grating and aluminium bar grating, is transforming how engineers, architects, and facility managers approach drainage challenges. Its unique properties deliver exceptional performance, longevity, and cost-efficiency, making it the smart choice for modern applications.

Shijiazhuang Chengsen Trading Co., Ltd., drawing on over 25 years of specialized grating production expertise and 18 years serving global markets, stands at the forefront of this revolution. With an unwavering commitment to quality adhering to stringent international standards, Chengsen understands the critical role superior drainage plays. Their vast experience in crafting everything from heavy-duty industrial solutions to intricate custom designs positions them as a trusted partner in deploying the exceptional advantages of aluminum grate mesh worldwide. Let's delve into why aluminum drainage solutions are becoming the gold standard.

Why Aluminum is Aluminum Grating And Aluminum Grate Mesh’S Reigns Supreme: Unbeatable Material Advantages

The fundamental superiority of aluminum grating and aluminum grate mesh begins with the inherent properties of aluminum itself. This lightweight yet remarkably strong metal offers a constellation of benefits that directly translate to superior drainage performance and longevity:

Exceptional Corrosion Resistance: This is arguably aluminum's most significant advantage for drainage. Aluminum naturally forms a protective oxide layer when exposed to air. This layer is incredibly stable and self-repairing, making aluminum grate mesh highly resistant to rust, decay, and degradation caused by water, moisture, salts (crucial for coastal or de-icing applications), and a wide range of chemicals commonly found in industrial runoff or urban environments. Unlike steel, which requires constant galvanizing or painting maintenance to resist corrosion, aluminum provides inherent, long-lasting protection. This translates directly to decades of reliable service with minimal upkeep, drastically reducing lifecycle costs.

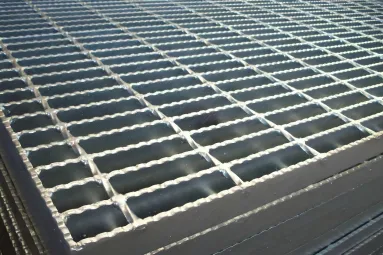

High Strength-to-Weight Ratio: Aluminium bar grating offers impressive load-bearing capacity while being significantly lighter than equivalent steel grating. This lightweight nature simplifies handling, transportation, and installation. Workers can maneuver panels more easily and safely, reducing installation time and labor costs. The reduced weight also lessens the structural load on supporting frameworks, potentially leading to savings in the underlying construction materials and design. Despite its lightness, properly designed and manufactured aluminum grating meets or exceeds the load requirements for pedestrian areas, vehicular traffic (like car parks), and even industrial settings.

Non-Sparking and Non-Magnetic: In environments where safety is paramount, such as oil and gas facilities, chemical plants, or areas with flammable vapors, the non-sparking nature of aluminum is a critical safety feature. Aluminum grate mesh eliminates the risk of sparks caused by impacts or friction, significantly reducing fire and explosion hazards. Its non-magnetic properties are also essential in specific sensitive electronic or medical facilities.

Aesthetic Versatility: Beyond pure function, aluminum grating offers aesthetic flexibility. It can be supplied with a natural mill finish, anodized in various colors for architectural integration or safety marking, or even powder-coated for enhanced durability and a wide range of color options. This allows it to blend seamlessly into urban landscapes, modern buildings, or specialized facilities where appearance matters. The clean lines and consistent surface of aluminium bar grating provide a modern, professional look.

Sustainability: Aluminum is one of the most recyclable materials on earth. Choosing aluminum grate mesh contributes to sustainable building practices. At the end of its exceptionally long service life, the material can be recycled repeatedly without loss of quality, minimizing environmental impact and conserving resources. The energy savings from its light weight during transport also add to its green credentials.

Chengsen's deep understanding of aluminum's metallurgy ensures their aluminum grating products leverage these inherent advantages to the fullest. Their rigorous quality control, from raw material sourcing to final inspection, guarantees that every piece of aluminum grate mesh delivers on the promise of strength, corrosion resistance, and longevity inherent in the material.

Engineered for Efficiency: Superior Hydraulic Performance of Aluminum Grate Mesh

Drainage isn't just about having a hole in the ground; it's about efficiently capturing and channeling water away as quickly and completely as possible. The design of aluminum grate mesh is intrinsically linked to its outstanding hydraulic performance:

Optimal Open Area: Aluminum grate mesh, particularly aluminium bar grating, is designed with a high percentage of open area relative to the total surface. This means a greater proportion of the surface allows water to pass through unimpeded. Compared to solid covers or gratings with smaller openings, aluminum grating significantly reduces the risk of surface ponding and flooding during heavy rainfall or sudden deluges. Water flows directly through the grate into the drainage channel below, minimizing slip hazards and water damage.

Smooth Flow Characteristics: The geometric design of the bars and cross members in aluminium bar grating creates minimal resistance to water flow. Water encountering the grate is efficiently captured and directed downwards without significant turbulence or backup. This smooth flow prevents debris from being "held back" on the surface unnecessarily and ensures maximum capacity is utilized. The precision manufacturing achieved by experienced producers like Chengsen ensures consistent opening sizes and smooth surfaces that facilitate this efficient flow.

Debris Management: While designed for high flow, aluminum grate mesh also effectively manages debris. The openings can be sized appropriately for the specific application – smaller openings for pedestrian areas prone to litter, larger openings for areas with larger debris like leaves. The linear nature of aluminium bar grating often allows debris to be swept across the surface easily during routine cleaning. The inherent smoothness of aluminum also reduces the tendency for debris to cling or snag compared to rougher surfaces.

Customizable Design for Specific Needs: Not all drainage challenges are identical. Aluminum grating offers immense flexibility in design. Bar spacing, bearing bar height and thickness, and mesh patterns can all be customized to meet specific hydraulic load requirements, anticipated debris types, and aesthetic preferences. Chengsen's team of expert CAD designers excels in creating tailored aluminum grate mesh layouts that optimize drainage performance for unique project specifications, whether it's a complex industrial floor, a scenic walkway, or a specialized trench system.

Trench Drain Integration: Aluminum grate mesh is the ideal cover for linear trench drains. Its strength supports loads over the trench, while its high open area ensures water enters the drain channel efficiently along its entire length. The lightweight nature makes lifting for maintenance simpler, and the corrosion resistance is crucial for the wet environment within the drain.

This engineered efficiency means systems utilizing aluminum grate mesh perform better under pressure, require less frequent clearing due to improved flow, and ultimately provide more reliable flood prevention and surface water management.

Built to Last: The Unmatched Durability and Longevity of Aluminium Bar Grating

The initial investment in drainage infrastructure is significant, making longevity a critical factor. This is where aluminium bar grating truly shines, offering a service life that often dwarfs alternatives, providing exceptional value over time:

Corrosion Resistance = Longevity: As emphasized earlier, the inherent corrosion resistance of aluminum is the cornerstone of its durability. Aluminium bar grating withstands constant exposure to water, humidity, salt spray, industrial pollutants, and atmospheric conditions without rusting, pitting, or structurally weakening. In harsh environments like coastal regions, chemical processing plants, food and beverage facilities (where cleaning chemicals are used), or roads subjected to de-icing salts, aluminum grating maintains its integrity and appearance where steel would rapidly deteriorate, even with protective coatings that eventually fail. This translates to decades of reliable service without the need for replacement.

Minimal Maintenance Requirements: Unlike steel grating that requires regular inspection, touch-up painting, or re-galvanizing to combat rust, aluminum grate mesh demands very little upkeep. Routine cleaning to remove debris is typically all that's needed. There's no need for costly and disruptive repainting programs or concerns about coating failure leading to accelerated corrosion. This drastically reduces the total cost of ownership over the lifespan of the installation. Facility managers appreciate the "install and forget" nature of quality aluminium bar grating.

Structural Integrity Retention: Aluminum does not become brittle at low temperatures and retains its strength well within standard environmental ranges. High-quality aluminum grating, manufactured to exacting standards like those practiced by Chengsen (adhering to international benchmarks like ANSI/NAAMM MBG531-88), ensures consistent load-bearing capacity throughout its lifespan. The material does not fatigue easily under cyclic loading typical in pedestrian or vehicular areas.

Resistance to Impact and Wear: While softer than steel, modern aluminum alloys used in grating offer excellent resistance to impact and abrasion. Aluminium bar grating holds up well under foot traffic, light vehicular loads, and the movement of equipment. In demanding industrial settings, heavier-duty aluminum grating profiles can be specified to handle significant loads.

UV Stability: Aluminum is not degraded by sunlight. The protective oxide layer remains stable, ensuring that the structural properties and appearance (whether mill finish, anodized, or powder-coated) of aluminum grate mesh are not compromised by prolonged sun exposure. This is a significant advantage over some polymer-based alternatives that can become brittle or fade over time.

Chengsen's commitment to "quality first" is paramount in delivering on this promise of longevity. Their 25+ years of production experience, rigorous adherence to international quality standards at every manufacturing stage (YB/T4001.1-2007, BS4592-1-1995, ANSI/NAAMM MBG531-88), and focus on material selection ensure that their aluminium bar grating doesn't just meet specifications but exceeds expectations for enduring performance. Their impressive 95% repeat order rate is a testament to the reliability and durability customers experience.

Addressing Your Questions: Aluminum Grate Mesh FAQ

Choosing the right drainage solution involves careful consideration. Here are answers to some frequently asked questions about aluminum grating, aluminum grate mesh, and aluminium bar grating:

How does aluminum grate mesh improve drainage efficiency compared to other materials?

Aluminum grate mesh, particularly aluminium bar grating, excels due to its high open area ratio, often exceeding 70-80%. This means significantly more surface area is available for water to pass through directly into the drainage system below, minimizing surface ponding and runoff. The smooth surface and geometric design of the bars create minimal flow resistance, allowing water to enter the drain channel quickly and efficiently. Unlike solid covers or gratings with smaller, complex openings, aluminum grating doesn't create bottlenecks. This superior hydraulic performance is crucial during heavy rainfall events, reducing flood risks and slip hazards. Additionally, its resistance to corrosion ensures the open area remains clear and functional over decades, unlike steel which can corrode and partially block openings.

Is aluminium bar grating strong enough for my application, like vehicle traffic?

Absolutely. The key advantage of aluminium bar grating is its exceptional strength-to-weight ratio. Modern aluminum alloys are engineered to provide significant load-bearing capacity. Reputable manufacturers like Chengsen design and produce aluminum grating to meet specific load classifications according to international standards (e.g., ANSI/NAAMM MBG531-88 pedestrian, vehicular, or heavy industrial loads). By selecting the appropriate bearing bar height, thickness, and spacing, aluminium bar grating can be engineered to safely support pedestrian foot traffic, light vehicles in car parks, forklifts in warehouses, and even heavy truck loads in industrial yards. Chengsen's expertise allows them to recommend and supply the perfect aluminum grate mesh specification for your specific load requirements.

What makes aluminum grating so low maintenance and long-lasting?

The secret lies in aluminum's inherent properties. Aluminum grating naturally forms a tough, protective oxide layer that shields it from corrosion caused by water, humidity, salt, and many chemicals. This layer is self-repairing if scratched. Unlike steel, which requires galvanizing (a coating that can wear or chip over time) and periodic repainting to prevent rust, aluminum grate mesh maintains its integrity without these interventions. This intrinsic corrosion resistance is the primary reason for its minimal maintenance needs – typically just routine cleaning to remove debris – and its exceptionally long lifespan, often several decades, even in harsh environments. Choosing aluminium bar grating translates to significantly lower lifetime costs by eliminating recurring maintenance expenses and premature replacement.

Can aluminum grate mesh be customized for unique project needs?

Yes, customization is a major strength of aluminum grate mesh. Reputable suppliers like Chengsen specialize in tailoring solutions. Key customizable aspects include:

Size and Shape: Panels can be fabricated to exact dimensions, including complex curves or special shapes (special-shaped steel grating expertise translates well to aluminum).

Load Capacity: Bar thickness, height, and spacing can be adjusted to meet specific load requirements (pedestrian, vehicular, industrial).

Mesh Pattern/Open Area: The design (e.g., standard aluminium bar grating, swaged, riveted) and opening size can be optimized for hydraulic efficiency and debris handling.

Surface Finish: Options include mill finish, clear or colored anodizing for enhanced corrosion resistance and color, or durable powder coating in a vast array of colors.

Fabrication: Features like lips, angles, or special fittings can be added. Chengsen's experienced CAD designers work directly with clients to translate specific requirements into precise, functional aluminum grating layouts and manufacturing drawings.

Why is aluminum grating considered a cost-effective choice in the long run?

While the initial material cost of aluminum grating might be higher than some alternatives like mild steel, its true cost-effectiveness shines over its lifecycle. Consider:

Minimal Maintenance: Eliminates costs for painting, re-galvanizing, or rust treatment over decades.

Longer Lifespan: Replaces the need for frequent replacements required by corroded steel or degraded plastics.

Reduced Installation Costs: Lightweight panels are easier and faster to handle and install, saving labor time.

Lower Structural Costs: Reduced weight can sometimes allow for lighter support structures.

Reduced Downtime: Minimal maintenance means less disruption to operations or public access.

Recyclability: High scrap value at end-of-life (though this is likely very far in the future!). When you factor in decades of reliable, low-maintenance service, aluminum grate mesh consistently proves to be the most economical choice over the total lifespan of a drainage system.

The evidence is clear: aluminum grate mesh, aluminum grating, and aluminium bar grating represent the pinnacle of modern drainage solutions. They offer an unbeatable combination of inherent corrosion resistance, exceptional strength with light weight, superior hydraulic efficiency, minimal long-term maintenance, significant longevity, and excellent safety features. Whether for critical infrastructure, demanding industrial settings, bustling urban environments, or sensitive architectural projects, aluminum drainage grates deliver unparalleled performance and value.

Shijiazhuang Chengsen Trading Co., Ltd. leverages over a quarter-century of specialized grating expertise to bring these benefits to the global market. Their unwavering commitment to quality, certified by adherence to the highest international standards, ensures every piece of aluminum grate mesh meets rigorous performance criteria. With a dedicated team of CAD designers ready to tackle custom requirements and a proven track record evidenced by 95% repeat orders and the supply of over 200,000 tons of grating products worldwide, Chengsen is more than just a supplier; they are a partner in building durable, efficient, and cost-effective drainage solutions.

By choosing aluminum grating, you're not just selecting a product; you're making a smart investment in the future resilience, safety, and cost-efficiency of your project. Experience the Chengsen difference – where quality is paramount, service is dedicated, and aluminum grate mesh solutions are engineered to excel. Contact Chengsen today to discover how their expertise can optimize your drainage needs.

Latest News

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

-

Ferrotech Grating: Durable Solutions for Modern Industry

NewsNov.17,2025

-

Trusted Aluminum Grating Manufacturers | Durable & Light

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA