Aug . 19, 2025 05:00 Back to list

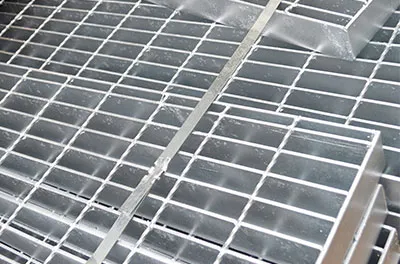

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

Elevating Industrial Safety and Efficiency with Advanced Steel Grating Solutions

In the demanding landscapes of modern industrial infrastructure, the integrity and performance of structural components are paramount. Among these, steel grating plays a pivotal role in ensuring operational safety, facilitating efficient workflows, and providing durable surfaces for various applications. Specifically, the 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh represents a high-performance solution engineered for environments where both robust load-bearing capabilities and exceptional corrosion resistance are critical. This specialized grating, characterized by its I-bar bearing bars, serrated surfaces, and hot-dip galvanized finish, is designed to meet stringent industry standards and withstand harsh conditions. Its unique construction optimizes strength-to-weight ratio while the serrated texture ensures superior slip resistance, a vital safety feature in wet or oily industrial settings. The hot-dip galvanization process provides a metallurgical bond of zinc, offering unparalleled protection against rust and extending the product’s operational lifespan significantly. This comprehensive guide delves into the intricate details of its manufacturing, technical specifications, diverse applications, and the inherent advantages that make it an indispensable choice for sectors ranging from petrochemical and power generation to wastewater treatment and marine engineering. Understanding these facets is crucial for B2B decision-makers seeking reliable, long-term investments in their infrastructure, ensuring compliance with global safety and performance benchmarks while optimizing total cost of ownership over decades of demanding use.

Unveiling the Manufacturing Prowess: The Journey of I-Bar Grating

The production of 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh involves a meticulous multi-stage process, beginning with the selection of high-grade steel. Typically, low-carbon steel, conforming to standards such as ASTM A36 or Q235, is chosen for its excellent weldability and structural integrity. The core of this grating lies in its 'I' shaped bearing bars, which are engineered to provide superior strength and stiffness compared to flat bars of equivalent weight, leading to more economical designs for specific load requirements. The manufacturing process initiates with precision cutting of these I-bars and round or square cross bars to exact dimensions. Following cutting, the crucial stage of resistance welding commences, where the bearing bars are mechanically locked into the cross bars under immense pressure and heat, creating a robust, monolithic panel. This welding technique ensures high load-bearing capacity and prevents bar rotation, a common issue in lower-quality gratings. A key differentiator for this product is the serration of the bearing bars, achieved by specialized rolling or cutting processes during the initial bar preparation. This serrated surface is vital for maximizing slip resistance, making the grating suitable for demanding environments like oil rigs, industrial platforms, and walkways where spills or wet conditions are prevalent, significantly enhancing site safety by reducing the risk of personnel accidents.

Post-welding, the steel grating panels undergo rigorous quality inspections to ensure dimensional accuracy, weld strength, and conformity to design specifications. This includes checks for bearing bar spacing, cross bar alignment, and overall panel flatness. Adherence to international standards like ANSI/NAAMM MBG 531-09 for metal bar grating and ISO 9001 for quality management systems is paramount, ensuring consistent product quality and performance. The final, and arguably most critical, step is the hot-dip galvanization process. After thorough cleaning and pickling to remove impurities, the steel panels are immersed in a molten zinc bath at approximately 450°C (840°F). This creates a metallurgically bonded zinc coating that encases the entire steel surface, providing an impermeable barrier against corrosion. This method offers significantly superior protection compared to paint or electroplating, yielding a typical service life of 20-50 years in various atmospheric conditions, depending on the environment's corrosivity. The galvanization process adds approximately 85 µm (3.4 mils) to the steel thickness, effectively sealing the material from oxygen and moisture, thereby preventing rust and extending the overall structural integrity of the 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh. This comprehensive manufacturing approach ensures a product that excels in durability, safety, and long-term cost-effectiveness, meeting the stringent requirements of petrochemical, metallurgical, and marine industries.

Technical Specifications and Performance Metrics for Optimal Selection

Understanding the precise technical specifications of 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh is paramount for engineers and procurement specialists to ensure optimal application and compliance with project requirements. The "25×3", "25×5", and "30×3" notations refer to critical dimensions of the bearing bars. For instance, "25×3" signifies a bearing bar depth of 25mm and a thickness of 3mm, while "25×5" indicates a 25mm depth with a 5mm thickness, and "30×3" denotes a 30mm depth with a 3mm thickness. These variations allow for selection based on specific load-bearing requirements and desired strength-to-weight ratios. The I-bar profile, characterized by its flange and web design, inherently offers enhanced stiffness and load deflection characteristics compared to a flat bar of the same nominal dimensions, leading to more economical designs for specific load requirements. Standard bearing bar spacing typically includes 30mm, 40mm, and 60mm center-to-center, while cross bar spacing usually ranges from 50mm or 100mm center-to-center. These spacings influence the open area percentage, which impacts light and air permeability, crucial for ventilation in certain industrial settings and compliance with fire safety regulations, ensuring efficient smoke and heat dispersal.

The hot-dip galvanized coating, applied in accordance with ASTM A123/A123M standards, typically provides a minimum coating thickness of 85 microns for grating over 6mm thick, ensuring robust corrosion protection. Load tables derived from NAAMM (National Association of Architectural Metal Manufacturers) standards dictate the maximum uniformly distributed loads and concentrated loads the grating can safely support for various spans and bearing bar sizes. For example, a 25x5 I-bar grating with 30mm bearing bar spacing can support significantly higher loads over a given span than a 25x3 I-bar, making material selection a critical design consideration. The serrated surface provides a coefficient of friction that is significantly higher than smooth grating, enhancing safety in areas prone to slick conditions. Furthermore, the maximum panel size is typically 1000mm x 6000mm, though custom sizes are readily available to minimize waste and optimize installation efficiency. Below is a detailed table outlining common parameters for these high-performance grating types, emphasizing their versatility and engineering precision necessary for applications in petrochemical, mining, and water treatment industries, where structural integrity under extreme conditions is non-negotiable.

| Parameter | 25×3 I-Bar Grating | 25×5 I-Bar Grating | 30×3 I-Bar Grating |

|---|---|---|---|

| Bearing Bar Dimensions (Depth x Thickness) | 25mm x 3mm | 25mm x 5mm | 30mm x 3mm |

| Material Standard | Low Carbon Steel (ASTM A36 / Q235) | ||

| Surface Treatment | Hot Dip Galvanized (ASTM A123/A123M) | ||

| Serration | Standard, for enhanced slip resistance (Coefficient of Friction > 0.6 in wet conditions) | ||

| Bearing Bar Spacing (C-C) | 30mm, 40mm, 60mm (Custom available for specific load distribution) | ||

| Cross Bar Spacing (C-C) | 50mm, 100mm (Custom available for varying pedestrian traffic) | ||

| Galvanization Thickness (Min.) | 85 microns (Average service life 20-50 years, depending on environment) | ||

| Typical Span Range (for optimal load) | Up to 1.5m (Designed for light to medium duty walkways) | Up to 2.5m (Ideal for heavy-duty platforms, vehicle traffic) | Up to 1.8m (Suitable for general industrial flooring) |

| Deflection Performance | Engineered for minimal deflection under specified loads (typically L/200 or 1/4 inch max) | ||

Beyond Basic Grating: Applications Across Critical Industries

The robust design and exceptional durability of 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh make it an ideal choice for a diverse array of industrial and commercial applications where safety, longevity, and performance are non-negotiable. In the petrochemical and oil & gas sectors, this grating is extensively used for offshore platforms, refineries, and chemical processing plants. Its superior corrosion resistance to harsh atmospheric conditions, combined with the excellent slip resistance provided by the serrated surface, ensures the safety of personnel on elevated walkways, platforms, and stair treads, even in the presence of oil, grease, or water spills. The I-bar's strength-to-weight benefits also reduce overall structural load, leading to more cost-effective designs in these often weight-sensitive environments, contributing to more efficient construction and material use. For power generation facilities, including thermal, nuclear, and hydroelectric plants, the grating serves as reliable flooring for boiler houses, turbine halls, and maintenance access areas, where its ability to withstand high temperatures and resist corrosion from steam or chemical exposure is crucial, ensuring uninterrupted operations and worker safety in demanding conditions.

The metallurgical industry, encompassing steel mills and aluminum smelters, benefits from the extreme durability of hot-dip galvanized I-bar grating, which can endure heavy loads, abrasive materials, and high-temperature environments. It's frequently deployed in furnace areas, rolling mills, and casting platforms, providing safe and robust surfaces for heavy machinery and personnel. In wastewater treatment plants and marine applications, the unparalleled corrosion protection offered by hot-dip galvanization is indispensable. These environments are notoriously aggressive, with constant exposure to moisture, chemicals, and salt water. The grating's ability to resist rust and degradation ensures long-term structural integrity for clarifiers, aeration tanks, docks, ship decks, and gangways. Furthermore, its application extends to commercial buildings for mezzanines, trench covers, and architectural facades, as well as bridge decking, where its strength and anti-slip properties contribute significantly to public safety and structural longevity. The versatility of 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh ensures its role as a foundational component in critical infrastructure globally, contributing to operational efficiency and worker safety across a spectrum of challenging industrial environments.

Strategic Advantages: Why I-Bar Grating Stands Out from the Competition

The selection of 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh over alternative grating types or materials presents a compelling case for discerning B2B buyers. One of its primary technical advantages lies in the I-bar profile itself. Unlike traditional flat bar grating, the I-bar geometry provides a superior moment of inertia for a given cross-sectional area, meaning it offers comparable strength and stiffness with less material. This results in a lighter weight product that can still achieve equivalent load-bearing capacities, leading to significant cost savings in raw materials, freight, and installation labor. Furthermore, the reduced weight translates to lower stress on supporting structures, potentially allowing for more economical structural designs, enhancing overall project efficiency. The serrated surface is another critical advantage, offering exceptional slip resistance, especially in industrial environments where oil, water, chemicals, or grease can create hazardous walking surfaces. This feature dramatically enhances worker safety and reduces the risk of costly accidents, a direct benefit that impacts operational continuity and insurance premiums, demonstrating its value beyond simple material cost.

The hot-dip galvanization process provides the ultimate defense against corrosion, a pervasive issue in industrial settings that can lead to costly maintenance, structural failure, and premature replacement. The metallurgical bond formed between the zinc and steel prevents under-film corrosion and rust creep, unlike painted or electroplated coatings which can chip or scratch, exposing the base metal. This extended lifespan, often exceeding 20-50 years, significantly reduces the total cost of ownership (TCO) over the product's lifecycle, delivering substantial long-term value. Beyond its inherent durability, the open mesh design of the grating facilitates excellent drainage of liquids, unimpeded passage of light and air, and efficient dispersal of heat, contributing to safer and more productive work environments. This combination of structural efficiency, enhanced safety features, and superior corrosion resistance positions 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh as a premium, cost-effective solution for a wide range of demanding industrial applications, far surpassing the performance of conventional grating types in critical aspects such as longevity, safety, and economic feasibility for long-term industrial projects.

| Feature | I-Bar Grating (e.g., 25x3 I-Bar) | Flat Bar Grating (e.g., 25x3 Flat Bar) |

|---|---|---|

| Strength-to-Weight Ratio | Superior (Higher stiffness for less material, often 15-20% lighter for equivalent strength) | Good (Standard performance) |

| Deflection under Load | Reduced (More efficient structural shape minimizes sag under load) | Higher (Less efficient for same material volume, potentially requiring thicker bars) |

| Material Economy | Better (Potentially lighter panels for same capacity, reducing raw material cost) | Standard (May require more material for the same load performance) |

| Surface Area for Galvanization | Slightly larger (Due to I-profile, ensures complete coverage and enhanced protective layer) | Standard |

| Aesthetics (Industrial) | Clean, modern appearance, often preferred for visible installations | Traditional industrial look |

| Typical Cost | Potentially higher unit cost, but lower total project cost due to weight/efficiency savings in supporting structures and transport | Lower unit cost, but potentially higher total project cost due to heavier structure and less efficient use of material |

Tailored Excellence: Custom Solutions and Manufacturer Expertise

While standard sizes of 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh cater to many industrial needs, critical infrastructure projects often require highly specific dimensions and configurations. A reputable manufacturer differentiates itself by offering comprehensive custom fabrication services, ensuring that the grating precisely fits the unique architectural and structural demands of any project. This includes custom panel sizes, cut-outs for pipes or equipment, and integrated toe plates or banding to enhance safety and finish. The ability to provide custom solutions minimizes on-site cutting and welding, which not only saves labor costs but also preserves the integrity of the hot-dip galvanized coating. On-site modifications can compromise the corrosion protection, leading to premature deterioration, whereas factory-fabricated custom pieces ensure uniform and complete galvanization of all exposed surfaces, including edges and cut-outs, preventing future rust spots and ensuring the full longevity of the product in challenging industrial environments.

When selecting a manufacturer for your 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh requirements, several factors underscore their authority and trustworthiness. Look for certifications such as ISO 9001, which signifies a commitment to consistent quality management, and adherence to relevant ASTM or ANSI standards, confirming product performance. A strong track record of successful projects, positive client testimonials, and a transparent delivery process are also indicative of a reliable partner. For instance, a manufacturer with over two decades of experience in the steel grating industry, who has supplied projects globally, demonstrates profound expertise. They should be able to provide detailed CAD drawings, structural analysis reports, and clear production timelines. Furthermore, a commitment to post-sales support, including installation guidance and warranty provisions, provides peace of mind. Collaborating with a manufacturer capable of delivering bespoke, high-quality solutions, backed by technical acumen and a proven history of reliability, is crucial for mitigating project risks and ensuring the long-term success and safety of your industrial installations, establishing a partnership based on trust and engineering excellence.

Real-World Impact: Case Studies and Industrial Applications

The practical effectiveness of 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh is best illustrated through its successful deployment in various demanding industrial settings. Consider a major petrochemical refinery expansion project in the Middle East, where thousands of square meters of this specific I-bar grating were utilized for elevated walkways, equipment platforms, and maintenance access points. The client's primary concerns were extreme temperatures, corrosive coastal air, and the constant presence of hydrocarbons. The hot-dip galvanized finish provided the necessary long-term corrosion resistance, extending the asset's life well beyond alternative coatings, and significantly reducing maintenance cycles. The serrated surface was critical for ensuring worker safety on platforms that could become slippery due to accidental spills or condensation, mitigating slip and fall risks in a high-hazard environment. The I-bar profile also allowed for longer spans between supports, simplifying structural design and reducing overall material usage for the supporting framework, which translated to faster installation times and lower project costs, demonstrating substantial economic and safety benefits.

Another compelling example comes from a large-scale power plant upgrade in Southeast Asia, involving the replacement of aging flooring in its turbine and boiler areas. Here, the existing grating had severely corroded and deformed under sustained heavy loads and high heat. The client specifically chose 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh due to its proven track record in extreme conditions. The material's ability to maintain its structural integrity under thermal expansion and contraction, combined with its robust load-bearing capacity for heavy machinery and constant foot traffic, was crucial. The anti-slip properties of the serrated surface provided a safer working environment for maintenance crews navigating complex machinery. This real-world application underscored the product's resilience and longevity, demonstrating its capacity to significantly improve operational safety and efficiency in critical infrastructure, showcasing its adaptability and reliability in diverse and challenging industrial landscapes, affirming its position as a leading solution for heavy-duty industrial flooring.

Ensuring Your Investment: Trust, Support, and Longevity

For B2B clients, the decision to invest in industrial grating goes beyond initial purchase price; it encompasses long-term reliability, support, and total cost of ownership. When procuring 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh, understanding the manufacturer's commitment to quality, service, and after-sales support is crucial. A transparent delivery cycle is a hallmark of a reliable supplier. Lead times can vary based on project size and customization requirements, but a professional manufacturer will provide clear, realistic timelines and keep clients informed throughout the production and logistics phases. Typical lead times for standard products might be 2-4 weeks, with custom orders potentially extending to 4-8 weeks, depending on complexity and current production schedules. Furthermore, a robust quality assurance program, including pre-shipment inspections and adherence to packing standards for secure transport, ensures that the product arrives on-site in pristine condition, ready for installation, minimizing delays and costly project setbacks.

A key component of trustworthiness is the provision of comprehensive warranties and responsive customer support. Reputable manufacturers offer warranties against manufacturing defects and premature corrosion for a specified period, typically 5 to 10 years, under normal usage conditions. This commitment demonstrates confidence in their product's durability and provides clients with crucial peace of mind. Beyond formal warranties, accessibility of technical support for installation guidance, maintenance advice, and troubleshooting is invaluable. A dedicated team that can address queries promptly and efficiently reinforces the manufacturer's reliability. Providing an FAQ section addresses common concerns proactively, reducing the need for direct inquiries and building immediate trust. For example: FAQ: Q: What are the key benefits of I-Bar over flat bar grating? A: I-Bar offers superior strength-to-weight ratio, leading to lighter panels and potentially longer spans for the same load, optimizing material use and reducing installation costs. Q: How long does hot-dip galvanization typically last? A: In most industrial atmospheric conditions, hot-dip galvanization provides protection for 20-50 years, significantly extending the product's lifespan compared to other coatings. Q: Can this grating be used outdoors in marine environments? A: Absolutely. The hot-dip galvanized finish provides excellent resistance to saltwater corrosion, making it highly suitable for marine and coastal applications. This comprehensive approach to quality, delivery, warranty, and support solidifies the long-term value proposition of investing in high-quality 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh.

Concluding Insights: The Future of Industrial Grating Solutions

The continuous evolution of industrial infrastructure demands materials that not only meet current safety and performance benchmarks but also anticipate future challenges. The 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh stands as a testament to this principle, embodying advanced engineering, superior material science, and robust manufacturing processes. Its inherent advantages in strength-to-weight ratio, unparalleled corrosion resistance through hot-dip galvanization, and enhanced safety provided by the serrated surface position it as a leading choice for a multitude of critical applications. From the unforgiving environments of petrochemical plants and offshore platforms to the high-traffic demands of power generation facilities and the corrosive conditions of wastewater treatment, this specialized grating consistently delivers on its promise of durability, longevity, and optimal operational safety. As industries continue to prioritize sustainability and efficiency, solutions that offer extended service life and reduced maintenance requirements become increasingly valuable, directly contributing to lower operational expenditures and environmental responsibility.

Looking forward, the trend in industrial grating solutions will likely continue towards further optimization in material performance, ease of installation, and enhanced environmental compatibility. Innovations in galvanization techniques, composite materials, and smart monitoring systems integrated into grating could become more prevalent, further augmenting the capabilities of products like the 25×3 25×5 30×3 Hot Dip Galvanized Serrated Welded Steel I Bar Grating Mesh. For B2B decision-makers, investing in such high-quality, engineered grating is not merely a procurement decision but a strategic commitment to operational excellence, risk mitigation, and long-term asset value. By understanding the detailed manufacturing processes, technical parameters, and diverse application benefits, companies can confidently select grating solutions that provide a superior return on investment and contribute significantly to a safer, more efficient industrial landscape, ensuring infrastructure resilience for decades to come in a rapidly evolving global economy.

References

- National Association of Architectural Metal Manufacturers (NAAMM). (2009). Metal Bar Grating Manual (ANSI/NAAMM MBG 531-09).

- ASTM International. (2017). ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ISO (International Organization for Standardization). ISO 9001:2015 - Quality management systems — Requirements.

- American Galvanizers Association (AGA). Durability of Hot-Dip Galvanizing.

- Koretsky, A. (2007). Engineering Materials Science. CRC Press.

This is the first article

Latest News

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

NewsAug.16,2025

-

Durable PVC Coated Wire Mesh Rolls for Fencing

NewsAug.15,2025

-

Fence Spikes for Sale - Effective Wall Security Deterrents

NewsAug.14,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA