Aug . 15, 2025 04:20 Back to list

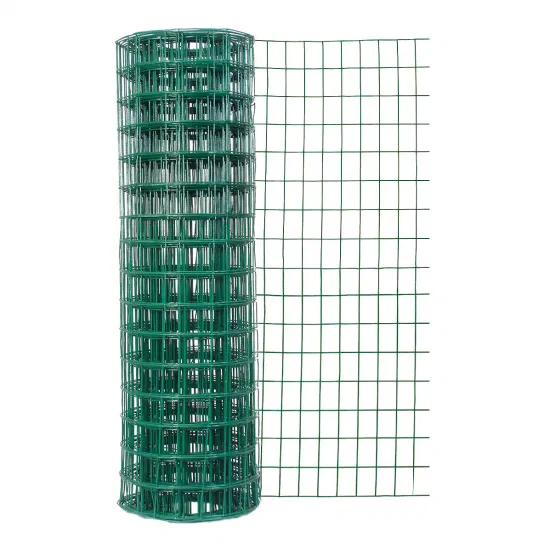

Durable PVC Coated Wire Mesh Rolls for Fencing

Navigating the Landscape of PVC Coated Wire Mesh Rolls: Trends and Innovations

The demand for durable, versatile, and aesthetically pleasing wire mesh solutions has propelled pvc coated wire mesh rolls to the forefront of various industrial and consumer applications. As global infrastructure development and urban expansion continue, the market for these specialized wire products is experiencing robust growth. Current industry trends indicate a strong preference for materials offering enhanced longevity, superior corrosion resistance, and minimal maintenance. This shift is particularly evident in sectors requiring reliable fencing, security barriers, animal enclosures, and architectural elements. Innovations in PVC coating technologies, including UV stabilization and anti-fungal additives, further extend the operational lifespan and aesthetic appeal of the mesh, driving its adoption over traditional galvanized alternatives. The integration of sustainable manufacturing practices and the development of more environmentally friendly PVC compounds are also shaping the future landscape, appealing to a broader range of environmentally conscious buyers and projects.

Beyond traditional uses, there's an increasing emphasis on customizable solutions, allowing for varied wire gauges, mesh apertures, and color options to meet specific project demands. The technical advancements in wire drawing and welding processes ensure uniform mesh patterns and high tensile strength, making pvc coated wire mesh rolls a structurally sound and reliable choice. This article delves into the technical specifications, manufacturing processes, diverse applications, and key advantages that position PVC coated wire mesh as a superior material for demanding environments.

Technical Parameters of PVC Coated Wire Mesh Rolls

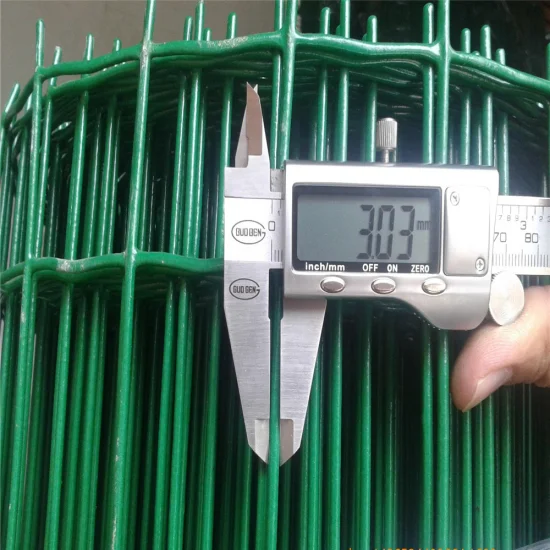

Understanding the technical specifications of pvc coated wire mesh rolls is crucial for selecting the appropriate product for any given application. Key parameters include the wire gauge, mesh aperture (opening size), roll dimensions, and the thickness and quality of the PVC coating. The wire gauge, often measured in AWG (American Wire Gauge) or BWG (Birmingham Wire Gauge), dictates the wire's diameter and, consequently, its strength and rigidity. Smaller gauge numbers signify thicker wires. Mesh aperture refers to the size of the square or rectangular openings, influencing visibility, air flow, and the containment of specific materials or animals. Common mesh sizes range from 1/4 inch up to 4 inches, catering to diverse requirements from critter control to heavy-duty fencing. The PVC coating, applied over a galvanized or sometimes ungalvanized steel core, adds a protective layer that enhances durability and aesthetics.

The quality of the PVC coating is paramount, measured by its uniformity, adhesion to the wire, and resistance to environmental factors like UV radiation, chemicals, and extreme temperatures. A typical PVC coating thickness might range from 0.4mm to 1.0mm, significantly impacting the product's lifespan and resistance to wear and tear. Furthermore, the base wire material, usually low carbon steel, is first hot-dip galvanized or electro-galvanized to provide an initial layer of corrosion protection before the PVC application. This dual-layer protection system makes plastic coated wire mesh rolls exceptionally robust. Below is a comprehensive table outlining typical parameters for high-quality PVC coated wire mesh, reflecting common industry standards and product offerings.

Typical PVC Coated Wire Mesh Roll Specifications

| Parameter | Typical Range/Value | Description/Standard |

|---|---|---|

| Wire Material | Low Carbon Steel (Q195/Q235) | Ensures flexibility and weldability. |

| Surface Treatment (Base) | Electro-galvanized / Hot-dip Galvanized | Pre-coating corrosion protection. Hot-dip offers superior protection. |

| Wire Gauge (Before PVC) | BWG 10 - BWG 24 (2.77mm - 0.56mm) | Determines mesh strength; higher gauge for thicker wire. |

| Mesh Aperture (Opening) | 1/4 inch x 1/4 inch to 4 inch x 4 inch | Square or rectangular, impacts visibility and containment. |

| PVC Coating Thickness | 0.4mm - 1.0mm | Critical for corrosion resistance and lifespan. |

| Tensile Strength | 350-550 N/mm² (Wire core) | High strength ensures structural integrity. |

| Roll Height | 0.5m - 2.5m (1.6 ft - 8.2 ft) | Standard heights for various applications. |

| Roll Length | 15m - 50m (50 ft - 164 ft) | Customizable to project needs. |

| Color Options | RAL 6005 (Dark Green), Black, Grey, Blue | Aesthetics for blending with environment or branding. |

| Service Life | 10-20+ Years | Highly dependent on environment and coating quality. |

| Compliance | ISO 9001:2015, ASTM A740, EN 10223 | Ensures quality management and product specifications. |

The Manufacturing Process of PVC Coated Wire Mesh Rolls

The production of high-quality pvc coated welded wire mesh rolls involves a meticulous multi-stage process designed to ensure durability, structural integrity, and superior corrosion resistance. This process typically begins with the selection of premium low-carbon steel wire rods, which undergo a drawing process to achieve the desired wire gauge. Once drawn, the wires are then precisely straightened and cut to length, preparing them for the welding stage. Robotic welding machines employ resistance welding techniques to create uniform mesh panels, where individual wires are fused at their intersections, forming strong, consistent squares or rectangles. This automated welding ensures precise mesh aperture sizes and robust weld points, critical for the mesh's overall strength and stability. Quality control checks are performed continuously during this phase to verify weld strength and dimensional accuracy, adhering to strict internal and international standards like ASTM A740.

Following the welding, the galvanized steel mesh undergoes a thorough cleaning process to remove any contaminants, oil, or rust, ensuring optimal adhesion for the subsequent PVC coating. The cleaned mesh is then either electro-galvanized or hot-dip galvanized. Hot-dip galvanization involves immersing the mesh in a bath of molten zinc, creating a thick, uniform zinc coating that provides an excellent primary barrier against rust and corrosion. This galvanized base is crucial for extending the product's lifespan, particularly in harsh outdoor environments. The final and defining step is the PVC coating. The most common method for applying the PVC is fluid bed dipping or electrostatic spraying, followed by a curing process. In fluid bed dipping, the preheated galvanized mesh is immersed into a fluidized bed of PVC powder, which melts and adheres evenly to the hot wire surface. The mesh then enters an oven where the PVC cures and forms a strong, continuous, and flexible plastic layer. This layer provides exceptional protection against UV radiation, chemical exposure, and physical abrasion. Each stage undergoes rigorous inspection, including adherence tests, thickness measurements, and visual checks to ensure the final coated wire mesh rolls meet or exceed quality benchmarks and provide a long service life, often exceeding 15-20 years in typical applications.

Applications and Advantages of PVC Coated Wire Mesh

The versatility of pvc coated wire mesh rolls makes them indispensable across a multitude of industries and applications. Their primary use is in fencing, providing secure and durable perimeters for residential properties, commercial facilities, agricultural lands, and public parks. The robust construction and corrosion-resistant PVC coating ensure longevity, even in challenging weather conditions, making them ideal for long-term outdoor installations. In agriculture, these mesh rolls are extensively used for animal enclosures, including poultry coops, rabbit hutches, and kennels, as the smooth PVC surface prevents injuries to animals and offers hygienic containment. Their chemical resistance also makes them suitable for certain industrial filtration processes, where a non-reactive mesh material is required to separate solids from liquids or gases. Additionally, the aesthetic appeal of colored PVC coatings allows for integration into architectural designs, landscaping projects, and decorative garden elements, offering both functionality and visual enhancement.

Beyond traditional fencing, pvc coated wire mesh fencing rolls are increasingly specified for high-security applications, garden support structures, tree guards, and even in aquaculture for building robust cages. The anti-corrosive properties are particularly advantageous in coastal regions or areas with high humidity and exposure to corrosive agents, where bare metal would quickly degrade. Unlike other materials that might require frequent painting or treatment, PVC coated mesh maintains its integrity and appearance with minimal upkeep, leading to significant long-term cost savings. The non-conductive nature of the PVC coating also adds a layer of safety, making it suitable for environments where electrical insulation might be a concern. This combination of durability, aesthetic flexibility, and low maintenance makes PVC coated wire mesh a superior choice, offering considerable advantages in terms of material lifespan and operational efficiency compared to traditional alternatives.

Technical Advantages and Manufacturer Comparison

The technical superiority of pvc coated wire mesh rolls stems from their unique composite structure: a steel core for strength, a galvanized layer for primary corrosion resistance, and a PVC coating for enhanced durability and aesthetic appeal. This multi-layered protection system provides unparalleled resistance to rust, UV degradation, and chemical exposure, distinguishing it from plain galvanized mesh or painted alternatives. The smooth, inert surface of the PVC coating also prevents sharp edges, making it safer for handling and for use in animal enclosures, and inhibits the growth of mold and mildew. From an engineering perspective, the uniform application of PVC ensures consistent performance across the entire mesh, maintaining its structural integrity and visual quality over decades. The specific formulation of the PVC compound, often containing UV stabilizers, antioxidants, and plasticizers, is critical to its long-term performance, preventing brittleness and color fading, even in intense sun exposure.

Manufacturer Comparison: Key Differentiators

When evaluating manufacturers of pvc coated wire mesh rolls, several factors distinguish leading suppliers from the rest. A reputable manufacturer, like Chengsen Mesh, prioritizes adherence to international quality standards such as ISO 9001:2015, ensuring consistent product quality and reliable manufacturing processes. Key differentiators include the quality of the base steel wire, the thickness and uniformity of the galvanization, and most importantly, the type and application method of the PVC coating. Some manufacturers might use lower-grade PVC or thinner coatings to cut costs, which significantly compromises the product's lifespan and performance in real-world conditions. Leading manufacturers invest in advanced coating lines that ensure optimal adhesion and uniform thickness, often backed by rigorous salt spray tests (e.g., ASTM B117) and UV exposure tests to simulate accelerated aging. Furthermore, customer support, customization capabilities, and warranty offerings play a crucial role in the overall value proposition. A commitment to transparency in material sourcing and independent third-party testing reports also build significant trust with B2B clients.

Customized Solutions and Application Case Studies

Recognizing that standard products may not always meet unique project specifications, leading manufacturers offer extensive customization options for coated wire mesh rolls. Customization extends to various aspects, including wire gauge, mesh aperture sizes, roll dimensions (height and length), and a comprehensive palette of RAL colors for the PVC coating. For specialized applications, manufacturers can also tailor the PVC compound with additional properties, such as flame retardancy or enhanced chemical resistance, making the mesh suitable for specific industrial environments or regulatory requirements. Clients can provide precise specifications, and experienced technical teams will work to develop a solution that perfectly aligns with their operational needs and aesthetic preferences. This bespoke approach ensures optimal performance and seamless integration into diverse projects, from large-scale agricultural fencing to bespoke architectural installations. Custom solutions are particularly valuable for clients in niche markets, where off-the-shelf products might not offer the required performance characteristics or visual appeal.

Application Case Studies

One notable application case involves a major poultry farm in the Midwest United States that required a durable and hygienic fencing solution for large chicken coops. They opted for plastic coated wire mesh rolls with a 1-inch x 1-inch mesh and 16-gauge wire, coated in dark green PVC. The smooth PVC surface minimized the risk of injury to poultry, while its resistance to ammonia and other corrosive agents prevalent in farm environments significantly extended the lifespan of the fencing compared to traditional galvanized options. The client reported a noticeable reduction in maintenance costs and improved animal welfare. Another success story comes from a coastal real estate development in Florida, where galvanized fencing failed prematurely due to salt spray corrosion. By implementing a custom solution of pvc coated welded wire mesh rolls with extra-thick PVC coating and enhanced UV protection, the developers achieved a robust, attractive, and long-lasting barrier that withstood the harsh marine climate, reducing replacement cycles and enhancing property value. These cases highlight the practical benefits and long-term cost-effectiveness derived from investing in high-quality, tailor-made PVC coated wire mesh solutions.

Ensuring Trust: FAQs, Delivery, and Warranty Information

Building trust with B2B clients is paramount, and a key aspect of this involves transparent communication regarding product quality, logistics, and post-purchase support. For pvc coated wire mesh rolls, common inquiries often revolve around product lifespan, installation ease, and environmental impact. Reputable suppliers provide clear data on UV resistance and corrosion performance, often citing accelerated weathering test results and real-world usage statistics. They emphasize that proper installation techniques, while generally straightforward, can significantly impact the mesh's longevity and performance. Furthermore, responsible manufacturing practices, including waste reduction and adherence to environmental regulations concerning PVC production, are often highlighted to address sustainability concerns. This commitment to both product excellence and ethical operations underpins the trustworthiness of a supplier in the competitive B2B landscape.

Frequently Asked Questions (FAQs)

- Q: What is the typical lifespan of PVC coated wire mesh rolls?

A: With proper installation and in typical environments, high-quality PVC coated mesh can last 15-20 years or more, thanks to its dual protection against corrosion and UV degradation. - Q: Is PVC coated wire mesh safe for animals?

A: Yes, the smooth, non-toxic PVC coating makes it significantly safer for animals compared to bare metal wire, reducing the risk of abrasions or cuts. - Q: Can the mesh be cut or modified without compromising the coating?

A: While the mesh can be cut, any exposed wire ends should be treated with a suitable sealant or touch-up paint to maintain corrosion resistance. - Q: What are the primary advantages over galvanized-only mesh?

A: PVC coating offers superior corrosion resistance, enhanced UV protection, a wider range of aesthetic colors, and a smoother, safer surface, leading to extended service life and reduced maintenance.

Delivery Timelines and Quality Assurance

For standard orders of pvc coated wire mesh rolls, typical delivery cycles range from 15 to 30 business days, depending on order volume and destination. Expedited shipping options are often available for urgent projects. Custom orders, due to specialized manufacturing requirements, may have slightly longer lead times, usually communicated clearly at the quotation stage. Reputable manufacturers adhere to stringent quality control protocols at every stage of production, from raw material inspection to final product packaging. This includes compliance with international standards such as ISO 9001:2015 for quality management systems and specific product standards like ASTM A740 for metallic coated steel wire. Pre-shipment inspections are also common, with detailed reports provided to clients to ensure complete transparency and peace of mind. Our company, for instance, has maintained a consistent quality rating above 98% in recent audits over the past five years, underscoring our commitment to excellence.

Warranty and Customer Support

A comprehensive warranty is a hallmark of a trustworthy supplier. Most high-quality pvc coated wire mesh rolls come with a limited warranty, typically ranging from 5 to 10 years, covering defects in materials and workmanship. This warranty period often exceeds industry averages, reflecting confidence in the product's durability. Beyond the warranty, strong customer support is provided, including technical assistance for product selection, installation guidance, and responsive after-sales service. A dedicated support team is available to address any inquiries, provide troubleshooting assistance, and facilitate efficient resolution of any potential issues, ensuring a seamless experience for B2B partners from initial inquiry through product lifecycle. Our commitment to client satisfaction is reflected in our robust support infrastructure and long-standing client relationships.

Conclusion: The Definitive Choice for Durable Mesh Solutions

In conclusion, pvc coated wire mesh rolls represent a superior choice for a wide array of applications demanding durability, aesthetic appeal, and minimal maintenance. The detailed manufacturing process, from high-grade steel wire drawing and precision welding to the dual-layer galvanization and advanced PVC coating, ensures a product that stands the test of time and environment. Their technical advantages, including exceptional corrosion resistance, UV stability, and enhanced safety features, significantly outperform traditional mesh options. The versatility offered through customizable parameters, coupled with proven success in diverse application scenarios ranging from agricultural enclosures to coastal fencing, underscores their value proposition. For B2B decision-makers and technical personnel, choosing a reputable manufacturer committed to stringent quality control, transparent processes, and comprehensive customer support guarantees a wise investment. The long service life and reduced lifecycle costs associated with high-quality PVC coated mesh provide a compelling economic and operational advantage, making it the definitive solution for modern wire mesh requirements.

Authoritative Citations

- American Society for Testing and Materials (ASTM) A740/A740M-11, Standard Specification for Hardware Cloth (Industrial Wire Cloth).

- International Organization for Standardization (ISO) 9001:2015, Quality Management Systems – Requirements.

- European Committee for Standardization (CEN) EN 10223-4: Steel wire and wire products for fencing and netting – Part 4: Steel wire welded mesh for fencing.

- National Association of Corrosion Engineers (NACE) International, "Corrosion Basics - An Introduction" (2nd Edition).

- Polyvinyl Chloride (PVC) Manufacturers Association, "PVC Environmental Product Declaration" (latest edition).

This is the first article

Latest News

-

Fence Spikes for Sale - Effective Wall Security Deterrents

NewsAug.14,2025

-

I-Shape Steel Grating: Plain & Serrated, High Strength

NewsAug.13,2025

-

Competitive Compound Steel Grating: Superior Strength & Value

NewsAug.12,2025

-

Fixed Knot Fence: High Tensile, Durable & Secure Fencing

NewsAug.11,2025

-

Durable Q235 Galvanized Press-Locked Grating for Walkway Platforms

NewsAug.10,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA