Aug . 18, 2025 04:40 Back to list

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

Advanced Perimeter Security: Understanding Hot-Dipped Galvanized Barbed Wire Fencing

In today's evolving global landscape, the demand for robust and reliable perimeter security solutions has never been more critical across diverse sectors, ranging from agricultural and industrial to high-security governmental installations. As infrastructure expands and asset protection becomes paramount, the choice of fencing materials plays a decisive role in ensuring long-term security, cost-effectiveness, and minimal maintenance. Among the various options available, 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing stands out as a superior choice due to its exceptional durability, formidable deterrent capabilities, and extended service life, making it an indispensable component for protecting property and controlling access. This specialized fencing solution, available in various roll weights to suit different project scales and logistical requirements, offers a significant advantage over conventional wire types, primarily owing to its Hot-Dipped Galvanized (HDG) coating. This advanced metallurgic process applies a thick, uniform layer of zinc that provides an unparalleled barrier against corrosion, abrasion, and the deteriorating effects of environmental exposure, including harsh weather conditions and chemical agents often found in industrial environments. The consistent quality and performance of these barbed wire products are pivotal for decision-makers who require dependable security infrastructure that delivers both immediate protection and long-term value, mitigating the need for frequent replacements or intensive upkeep.

The market trend strongly indicates a growing preference for galvanized products due to their enhanced longevity and reduced lifecycle costs. Industries such as petrochemicals, mining, utilities, and large-scale agriculture are increasingly specifying HDG barbed wire for its proven resilience in demanding conditions, where standard fencing would quickly degrade. This shift reflects a broader industry understanding that initial investment in high-quality, corrosion-resistant materials yields substantial returns through improved security efficacy and diminished operational expenditures over decades. Furthermore, the varying roll weights, specifically 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing, allow for tailored procurement, enabling project managers to optimize logistics, handling, and installation efficiency based on the size and scope of their security perimeters. For smaller, localized applications or repairs, lighter rolls like 10kg or 15kg are practical, offering ease of transport and deployment. Conversely, for extensive border fortifications or large industrial complexes, the 50kg rolls minimize splices and maximize continuous coverage, enhancing both security integrity and installation speed. This strategic adaptability makes HDG barbed wire an economically sound and technically superior option for a wide array of perimeter security needs, ensuring robust protection that withstands the test of time and environmental challenges, thereby fulfilling the stringent requirements of modern industrial and public security applications.

Manufacturing Process: Craftsmanship Unveiled

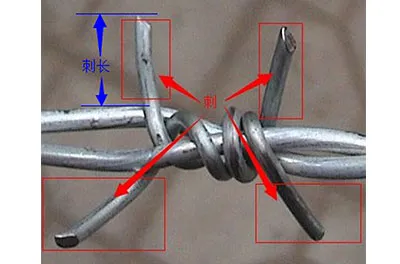

The production of 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing involves a meticulous, multi-stage manufacturing process designed to achieve superior strength, durability, and corrosion resistance. It commences with the careful selection of high-grade, low-carbon steel wire rods, which serve as the foundational material. These rods are first drawn into precise gauges, ensuring uniform diameter and optimal tensile strength necessary for forming durable strands. Following wire drawing, the steel wires undergo a specialized barbing process, where multiple strands are twisted together, and sharp barbs are strategically interwoven at specified intervals. This twisting can be single strand, double strand, or reverse twist, with reverse twist offering enhanced resistance to unwinding and increased structural integrity. The precision of this mechanical process is critical, as it dictates the effectiveness of the deterrent and the overall stability of the fence line. Advanced CNC machinery often facilitates this stage, ensuring consistent barb spacing and firm attachment, which are essential for preventing breaches and maintaining security efficacy across varying terrains and conditions. The consistency in barb placement, typically measured in inches, and the sharpness of the barbs themselves, contribute significantly to the fence's effectiveness as a physical and psychological barrier. This initial phase sets the stage for the crucial galvanization process, without which the wire's lifespan would be severely limited, particularly in outdoor environments.

The cornerstone of the product's exceptional longevity and performance lies in the Hot-Dipped Galvanization (HDG) process. After barbing, the wire coils are thoroughly cleaned through a series of pickling baths to remove all impurities, rust, and scale, ensuring a perfectly clean surface for zinc adhesion. This preparation is followed by a fluxing stage, which prepares the steel surface for metallurgical bonding with the molten zinc. The wire is then immersed into a bath of molten zinc heated to approximately 450°C (840°F). During this immersion, the iron in the steel metallurgically reacts with the molten zinc to form a series of zinc-iron alloy layers, which are then covered by a pure zinc outer layer. This creates a highly durable, sacrificial coating that provides both barrier protection and cathodic protection, meaning the zinc will corrode preferentially to the steel, protecting it even if the coating is scratched. The thickness of this zinc coating is rigorously controlled, typically measured in grams per square meter (g/m²), and directly correlates to the product's lifespan in various environmental conditions. Post-galvanization, the wire is cooled and then coiled into the specified weights – 10kg, 15kg, 20kg, 25kg, or 50kg – ensuring ease of handling and deployment for different project requirements. Throughout this entire process, stringent quality control measures are implemented, adhering to international standards such as ISO 9001, ASTM A121 (Standard Specification for Metallic-Coated Carbon Steel Barbed Wire), and ANSI standards. These checks include visual inspections, zinc coating thickness tests using magnetic or eddy current gauges, adhesion tests to ensure the zinc does not flake, and tensile strength tests to verify the wire's resistance to breaking under tension. This meticulous process ensures that each roll of barbed wire fencing meets the highest standards for performance, longevity, and reliability, thereby guaranteeing its effectiveness in critical security applications.

Technical Specifications & Performance Parameters

Understanding the precise technical specifications of 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing is essential for procurement specialists and engineers to ensure the selected product aligns perfectly with project requirements and environmental conditions. The performance of barbed wire is not merely about its physical presence but about its engineered properties that define its strength, longevity, and deterrent effectiveness. Key parameters include the wire gauge, typically measured in British Wire Gauge (BWG) or metric millimeters, which determines the wire's diameter and inherent strength. Common gauges for barbed wire range from 12.5 BWG (2.5mm) to 15.5 BWG (1.8mm), with heavier gauges offering greater resistance to cutting and bending. The strand configuration, whether single or double strand, and the type of twist (e.g., reverse twist) significantly impact the wire's structural integrity and ability to withstand tampering. Barb spacing, the distance between successive sets of barbs, usually ranges from 75mm (3 inches) to 150mm (6 inches), influencing the density of deterrent points. The length and sharpness of the barbs are also critical for maximizing their inhibitory effect. Crucially, the zinc coating thickness, typically specified in grams per square meter (g/m²), is a direct indicator of the product's corrosion resistance and expected lifespan. For instance, a coating of 275 g/m² offers significantly extended durability compared to thinner coatings, making it ideal for harsh marine or industrial environments where corrosion is an accelerated threat. Furthermore, the tensile strength of the steel wire, expressed in Newtons per square millimeter (N/mm²), quantifies its resistance to breaking under tension, a vital characteristic for maintaining fence integrity against impact or stress. These parameters are rigorously tested to comply with international standards such as ASTM A121, ensuring consistent quality and predictable performance in diverse applications. Below is a detailed table summarizing typical specifications for this high-performance barbed wire.

| Parameter | Specification Range | Unit | Relevant Standard |

|---|---|---|---|

| Wire Material | Low Carbon Steel (Q195/Q235) | N/A | ASTM A121 |

| Wire Gauge (Line Wire) | 12.5 BWG - 15.5 BWG | BWG | ASTM A121 |

| Wire Diameter (Line Wire) | 1.8 mm - 2.8 mm | mm | ASTM A121 |

| Strand Count | 2 Strands | N/A | N/A |

| Twist Type | Double Twisted, Reverse Twisted | N/A | N/A |

| Barb Spacing | 75 mm - 150 mm (3-6 inches) | mm / inches | ASTM A121 |

| Zinc Coating Thickness (Type III) | Min. 245 g/m² - 275 g/m² | g/m² | ASTM A121 |

| Tensile Strength | 350-550 N/mm² | N/mm² | ASTM A121 |

| Roll Weights Available | 10 kg, 15 kg, 20 kg, 25 kg, 50 kg | kg | N/A |

| Estimated Service Life | 20+ Years (Rural/Suburban), 10-20 Years (Industrial/Coastal) | Years | Industry Standard |

These detailed technical specifications highlight why the investment in high-quality 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing is a strategic decision for B2B applications. The combination of robust wire material, precision barbing, and the superior protection afforded by a heavy hot-dipped galvanized coating ensures that this fencing solution delivers unparalleled security and longevity, minimizing the need for costly replacements and intensive maintenance cycles. The adherence to rigorous testing standards, such as those prescribed by ASTM, provides an additional layer of assurance regarding the product's performance and compliance with industry benchmarks. Furthermore, the availability of various roll weights facilitates efficient project management, allowing for optimized transportation, handling, and installation logistics based on the scale and remoteness of the site. This adaptability, combined with its inherent strength and deterrent properties, makes it the preferred choice for environments requiring steadfast and enduring perimeter defense against unauthorized access and livestock containment in agricultural settings. The projected service life, extending well beyond two decades in favorable conditions, offers a compelling return on investment by significantly reducing long-term operational costs associated with perimeter security infrastructure.

Applications and Strategic Advantages

The versatility and robustness of 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing make it an indispensable security asset across an extensive spectrum of industries and applications, fulfilling critical roles in perimeter defense, access control, and asset protection. In the agricultural sector, it is widely utilized for livestock containment, defining property boundaries, and protecting crops from wildlife, where its formidable nature prevents animal breaches and ensures the integrity of vast farmlands. Industrial facilities, including manufacturing plants, warehouses, and storage yards, deploy this fencing to safeguard valuable equipment, raw materials, and finished goods against theft and unauthorized entry. Its application extends to high-security environments such as military bases, correctional facilities, and border protection zones, where it forms a critical layer of defense, deterring intrusion and enhancing overall site security. Furthermore, in infrastructure projects like power substations, communication towers, and railway lines, it serves as an effective barrier to prevent trespassing and vandalism, thereby ensuring operational continuity and public safety. Construction sites often rely on it for temporary security during development phases, protecting equipment and materials from theft and ensuring site safety. The inherent anti-climb properties and sharp barbs provide a strong psychological and physical deterrent, making illicit entry significantly more challenging and risky, thereby enhancing the overall security posture of any enclosed area. This widespread adoption underscores its proven efficacy in diverse, challenging settings.

The strategic advantages of opting for 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing are manifold, extending beyond mere physical deterrence to encompass long-term operational and economic benefits. Chief among these is its superior corrosion resistance, directly attributable to the robust Hot-Dipped Galvanized (HDG) coating. This thick zinc layer forms a metallurgically bonded barrier that is far more durable than electro-galvanized or pre-galvanized alternatives, offering exceptional protection against rust, acid rain, saline environments, and industrial pollutants. This significantly extends the product's service life, often exceeding 20 years even in harsh coastal or industrial settings, drastically reducing the frequency and cost of replacement and maintenance cycles. Its high tensile strength ensures remarkable resistance to cutting, stretching, and impact, maintaining the integrity of the fence line under pressure. This inherent robustness translates into minimal maintenance requirements, as the HDG coating prevents premature degradation, saving businesses substantial operational expenditures over the product's lifespan. Furthermore, the formidable visual and physical deterrent posed by the sharp barbs acts as a powerful disincentive to intruders, enhancing overall security without requiring active monitoring in all instances. This combination of longevity, resilience, and effective deterrence makes HDG barbed wire a cost-effective and highly reliable solution for demanding security applications where failure is not an option, providing peace of mind and enduring protection for critical assets and boundaries in sectors like petrochemical, metallurgy, and water treatment where corrosive environments are prevalent.

Market Analysis, Customization, and Case Studies

The global market for perimeter security solutions is experiencing steady growth, driven by increasing geopolitical instability, rising concerns over property protection, and expanding industrial infrastructure. Within this market, the segment for high-durability fencing, particularly 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing, continues to exhibit robust demand due to its unparalleled balance of cost-effectiveness, deterrent capability, and extended operational lifespan. Decision-makers in B2B sectors, from large agricultural corporations to critical infrastructure operators, are increasingly prioritizing products that offer superior longevity and minimal maintenance, thereby reducing the total cost of ownership over decades. When evaluating manufacturers, key factors influencing procurement decisions include the adherence to international quality standards such as ISO 9001, the proven consistency of the Hot-Dipped Galvanization process (evidenced by uniform zinc coating thickness and adhesion tests), and the manufacturer's capacity for customization. Reputable manufacturers distinguish themselves not just by product specifications but also by their comprehensive quality control protocols, verifiable certifications, and a track record of successful deployments in challenging environments. Companies with extensive service histories and a commitment to continuous product improvement, often incorporating feedback from field applications, are generally preferred. This rigorous selection process ensures that the chosen barbed wire fencing will perform as expected under specified conditions, providing reliable security for mission-critical assets and operations, aligning with long-term strategic planning for infrastructure protection and security investments.

One of the significant advantages for large-scale projects is the availability of customization options for 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing. Beyond the standard 10kg, 15kg, 20kg, 25kg, and 50kg roll weights, manufacturers can offer specific coil lengths, barb spacing, wire gauges, and even specialized packaging to meet unique logistical or installation demands. For example, a project requiring rapid deployment across vast, remote stretches might benefit from custom 50kg rolls that minimize splicing points and facilitate machine-assisted installation. Conversely, for detailed security overlays on existing structures, smaller 10kg rolls might be more practical for manual handling and precise application. An illustrative case study involves a major pipeline infrastructure project in a corrosive desert environment. The client initially considered standard galvanized wire, but after consulting with experts and evaluating lifecycle costs, opted for HDG barbed wire with a heavy zinc coating (Type III, min. 275 g/m²). This strategic decision resulted in a projected service life exceeding 25 years, significantly reducing the maintenance budget and eliminating the need for costly replacements every 5-7 years, which would have been necessary with lesser quality materials. Another example involved a large-scale agricultural cooperative needing to secure thousands of acres of farmland. They required varying roll sizes: 50kg for perimeter fencing bordering public roads and 20kg for internal sectioning where more frequent access was needed. The ability to supply a consistent product quality across these diverse roll weights simplified procurement and ensured uniform security standards throughout the property. These real-world applications underscore the product's adaptability and the critical role of material science and strategic procurement in achieving long-term security objectives and optimal return on investment, showcasing its capability to integrate into complex security systems, providing robust, maintenance-minimal solutions for diverse operational needs.

Frequently Asked Questions (FAQ)

-

Q: What makes hot-dipped galvanized barbed wire superior to other types?

Hot-dipped galvanization (HDG) creates a metallurgical bond between the steel wire and a thick, uniform zinc coating, typically providing 3-5 times the corrosion protection of electro-galvanized wire. This robust coating resists rust, abrasion, and harsh environmental elements like salt spray and industrial chemicals, significantly extending the product's lifespan to 20+ years in many conditions. Its sacrificial protection means the zinc corrodes before the steel, safeguarding the wire even if scratched. This superior durability translates into lower long-term maintenance and replacement costs, making it a more economical choice over its lifecycle for 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing.

-

Q: What are the typical service life expectations for HDG barbed wire?

The service life of HDG barbed wire is highly dependent on the zinc coating thickness and the aggressiveness of the environment. In typical rural or suburban settings with Type III (heavy) galvanization (e.g., 275 g/m²), it can easily last 20 to 30 years or more. In more corrosive environments, such as coastal regions with high salt exposure or industrial areas with chemical pollutants, the lifespan might range from 10 to 20 years. Regular inspection and minimal maintenance can further extend this longevity. The substantial coating ensures enduring protection for 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing applications.

-

Q: How do I choose the right roll weight (e.g., 10kg vs. 50kg)?

The selection of roll weight depends primarily on the project scale, logistical considerations, and installation methods. Lighter rolls (10kg, 15kg) are more manageable for manual handling, smaller perimeter extensions, repairs, or areas with difficult access. They are ideal for projects requiring precise application or where heavy machinery is impractical. Conversely, heavier rolls (25kg, 50kg) are highly efficient for large-scale industrial, agricultural, or governmental projects spanning vast areas. They minimize the number of splices, accelerate machine-assisted installation, and reduce overall labor costs by maximizing continuous coverage, making them ideal for extensive perimeter security with 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing.

-

Q: Is this barbed wire suitable for coastal areas?

Yes, 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing is highly suitable for coastal environments, provided it features a robust zinc coating (Type III galvanization is recommended). The thick zinc layer offers excellent resistance to the corrosive effects of salt spray and high humidity prevalent in maritime climates. While no material is entirely impervious to extreme conditions, HDG barbed wire significantly outperforms other types in such environments, providing extended service life and reliable security, thereby preventing premature degradation that would necessitate frequent replacements in these challenging conditions.

-

Q: What are the typical installation requirements for this product?

Installation of 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing typically involves robust fencing posts (wood, metal, or concrete) spaced at regular intervals, often 2.5 to 4 meters apart, to ensure proper tension and stability. The wire is stretched taut and securely fastened to the posts using specialized clips or ties. Corner posts and end posts often require bracing to withstand the high tension. For enhanced security, multiple strands are usually installed in parallel, sometimes topped with additional deterrents like razor wire. Proper safety gear (heavy-duty gloves, eye protection) is crucial during installation due to the sharp barbs. Professional installation is recommended for large or high-security projects to ensure optimal effectiveness and safety.

Delivery and Warranty Commitment

Our commitment to client satisfaction extends beyond the provision of high-quality 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing to encompass seamless logistics and robust after-sales support. We understand that timely delivery is critical for project timelines and operational continuity, which is why we maintain efficient production schedules and collaborate with reliable logistics partners to ensure prompt and secure dispatch of orders globally. Standard delivery timelines typically range from 2 to 4 weeks, depending on order volume and destination, with expedited options available for urgent requirements. Each shipment undergoes rigorous pre-delivery inspection to confirm product integrity and adherence to specifications, ensuring that the fencing arrives in optimal condition, ready for immediate deployment. Our packaging is designed to protect the galvanized coating and wire integrity during transit, preventing damage and ensuring that the product maintains its high performance characteristics from our factory to your site. This meticulous attention to logistics minimizes potential delays and logistical complications, ensuring that your security projects can proceed as planned without unforeseen interruptions, thereby maintaining operational efficiency and project budget adherence.

Furthermore, our confidence in the superior quality and durability of our 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing is underpinned by a comprehensive warranty commitment and dedicated customer support. We offer a manufacturer's warranty against defects in material and workmanship, typically covering a period of 5 to 10 years, depending on the specific product variant and application. This warranty reflects our adherence to stringent quality control protocols and the proven longevity of the hot-dipped galvanized coating. Beyond the initial purchase, our experienced technical support team is readily available to provide expert guidance on product selection, installation best practices, and maintenance recommendations. Whether you require assistance with large-scale project planning or need clarification on technical specifications, our specialists are committed to ensuring your satisfaction and the long-term success of your security infrastructure. We believe that exceptional customer service is as crucial as product quality, and we strive to build enduring partnerships with our B2B clients by offering reliable support and expert advice throughout the entire lifecycle of our fencing solutions. This holistic approach ensures that your investment in our barbed wire fencing is not just a procurement decision but a long-term partnership in security and reliability.

Conclusion: The Enduring Value of HDG Barbed Wire

In summary, the strategic adoption of 10kgs 15kgs 20kgs 25kgs 50kg Hot Dipped Galvanized Barbed Wire Mesh Fencing represents a forward-thinking investment in long-term security and operational efficiency for a myriad of industrial, agricultural, and high-security applications. Its inherent design, meticulous manufacturing process, and, critically, the robust Hot-Dipped Galvanized coating combine to deliver unparalleled corrosion resistance, exceptional tensile strength, and superior deterrent capabilities. This results in a fencing solution that not only provides formidable protection against unauthorized access and animal breaches but also boasts an extended service life of several decades, even in the most challenging environmental conditions, from saline coastal zones to chemically aggressive industrial sites. The adaptability offered by various roll weights—10kg, 15kg, 20kg, 25kg, and 50kg—ensures that projects of any scale, from localized repairs to extensive border fortifications, can be outfitted with precisely the right product, optimizing logistics, handling, and installation efficiency. By choosing this high-performance barbed wire, decision-makers are not merely acquiring a physical barrier but are investing in a sustainable security infrastructure that minimizes maintenance requirements, reduces lifecycle costs, and provides enduring peace of mind. This commitment to quality, backed by adherence to international standards and comprehensive customer support, solidifies its position as the premier choice for reliable and cost-effective perimeter defense, aligning with the evolving needs of modern B2B security demands and delivering demonstrable returns on investment through enhanced asset protection and operational continuity.

References

- American Society for Testing and Materials (ASTM) International. ASTM A121/A121M - Standard Specification for Metallic-Coated Carbon Steel Barbed Wire.

- International Organization for Standardization (ISO). ISO 9001: Quality management systems – Requirements.

- National Association of Corrosion Engineers (NACE International). The Science of Galvanized Steel: A Comprehensive Guide to Corrosion Protection.

- Galvanizers Association. Hot Dip Galvanizing: A Guide to the Process and Performance.

- Metal Construction Association (MCA). Durability of Zinc Coatings on Steel.

This is the first article

Latest News

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

NewsAug.16,2025

-

Durable PVC Coated Wire Mesh Rolls for Fencing

NewsAug.15,2025

-

Fence Spikes for Sale - Effective Wall Security Deterrents

NewsAug.14,2025

-

I-Shape Steel Grating: Plain & Serrated, High Strength

NewsAug.13,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA