Sep . 25, 2025 17:12 Back to list

Durable Stainless Steel Window Screen | Rust-Proof & Strong

Introduction to Advanced Window Screening Solutions

In industrial, commercial, and residential applications, the integrity of a protective barrier is paramount, especially against environmental elements and pests. For decades, traditional screening materials have served this purpose, but with evolving demands for durability, aesthetic integration, and specialized performance, the engineering of robust screening solutions has become critical. This article delves into the superior characteristics and diverse applications of stainless steel window screen, a product engineered to deliver unparalleled longevity and resistance in the most demanding environments.

Beyond conventional insect barriers, modern window screening functions as a critical component in maintaining indoor air quality, enhancing security, and optimizing energy efficiency. We will explore the technical nuances, manufacturing precision, and strategic deployment of these advanced screens, comparing them with alternatives like aluminum window screen and conventional insect screens for windows, to highlight why high-grade metal window screen mesh represents a vital investment for discerning B2B clients.

Industry Trends in High-Performance Screening

The market for window screening is experiencing significant shifts driven by regulatory changes, increased demand for sustainable and durable materials, and evolving architectural design philosophies. Key trends include:

- Durability & Longevity: A strong move away from short-lifespan materials towards high-strength alloys like stainless steel and specialized aluminum window screen variants that minimize replacement costs and environmental impact.

- Enhanced Security: The integration of heavy-gauge metal window screen mesh for anti-vandalism and intruder deterrence, particularly in commercial and industrial settings.

- Corrosion Resistance: Growing adoption of materials with superior corrosion resistance, crucial for coastal regions, industrial zones, and environments exposed to harsh chemicals.

- Aesthetic Integration: Demand for screens that offer high visibility and seamless integration with modern building facades, without compromising on protective qualities.

- Sustainability & Recyclability: Preference for materials that are recyclable and have a lower carbon footprint throughout their lifecycle.

These trends underscore the strategic importance of investing in robust solutions such as the stainless steel window screen, which consistently outperforms traditional options in critical performance metrics.

Manufacturing Process of Stainless Steel Window Screen

The production of a high-quality stainless steel window screen is a meticulous process, ensuring uniformity, strength, and longevity. Unlike casting or forging processes common in other metal industries, screen manufacturing relies heavily on precision wire drawing and weaving. The primary material used is typically high-grade austenitic stainless steel, predominantly AISI 304 or AISI 316, renowned for its excellent corrosion resistance and mechanical properties.

The process flow can be schematically outlined as follows:

- Wire Rod Procurement: High-quality stainless steel wire rods are sourced from certified mills, typically conforming to ASTM A276 or equivalent international standards.

- Wire Drawing: The wire rods undergo a cold drawing process through a series of dies to achieve the precise wire diameter required for specific mesh specifications. This process increases tensile strength and improves surface finish.

- Annealing (Optional): Depending on desired flexibility and weave characteristics, the drawn wire may be annealed (heat-treated) to reduce internal stresses and enhance ductility.

- Weaving Preparation: Wires are wound onto bobbins for the warp (longitudinal) and weft (transverse) threads, prepared for the weaving looms.

- Precision Weaving: Utilizing specialized weaving looms, the stainless steel wires are interlaced to form the mesh. Common weave types include plain weave (warp and weft wires cross alternately) and twill weave (weft wire passes over two warp wires, then under one, creating a diagonal pattern). The choice of weave impacts aperture size, open area, and mechanical strength.

- Degreasing & Cleaning: Post-weaving, the mesh rolls are thoroughly cleaned to remove any lubricants, oils, or residues from the manufacturing process, ensuring a clean, uniform surface.

- Edge Treatment & Finishing: Edges are typically selvaged or trimmed to prevent fraying and ensure a neat finish. The mesh can then be flattened, rolled, or cut to specific dimensions.

- Quality Control & Testing: Each batch undergoes rigorous inspection to verify mesh count, wire diameter, open area, and dimensional accuracy. Material composition can be verified using spectrographic analysis. Performance tests include tensile strength, burst pressure (for filtration meshes), and corrosion resistance, often adhering to ISO 9001 quality management systems and ASTM E2016 for industrial woven wire cloth.

- Packaging: Finished rolls or sheets are carefully packaged to prevent damage during transit, often with protective wrapping and robust crating.

The target industries for these highly durable screens include petrochemical, metallurgy, mining, water supply & drainage, pharmaceuticals, and food processing, where their superior corrosion resistance and inertness are critical. Advantages in typical application scenarios include enhanced energy saving through efficient ventilation and reduced reliance on air conditioning, and unparalleled corrosion resistance leading to significantly extended service life, often exceeding 20 years in challenging environments compared to 5-10 years for aluminum alternatives.

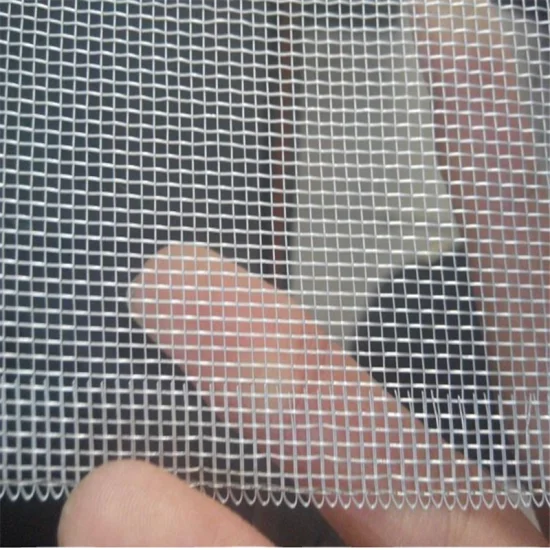

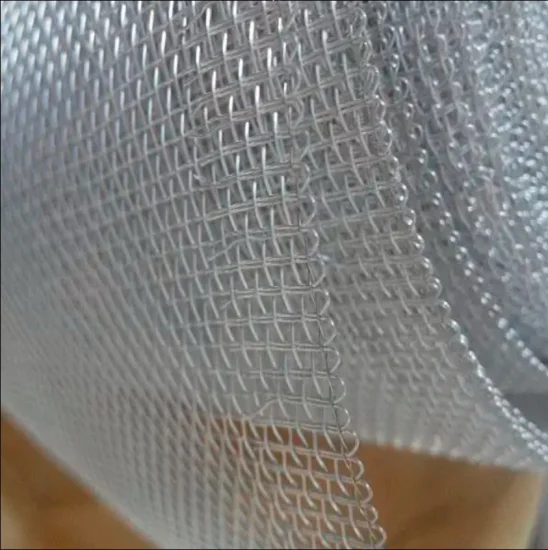

Precision weaving of stainless steel window screen for optimal mesh integrity.

Technical Specifications and Parameters

The performance of a stainless steel window screen is defined by several key technical parameters. These specifications determine its suitability for various applications, ranging from fine particle filtration to robust security barriers. Understanding these metrics is essential for precise engineering and procurement decisions.

Key Specifications Table: Stainless Steel Window Screen (Common Grades)

| Parameter | Typical Values (AISI 304/316) | Significance |

|---|---|---|

| Material Grade | AISI 304, AISI 316 | 304: General purpose, good corrosion resistance. 316: Enhanced resistance to chlorides, ideal for marine/chemical environments. |

| Mesh Count (per inch) | 8 x 8 to 120 x 120 | Number of wires per linear inch. Higher count means finer mesh, smaller apertures. |

| Wire Diameter | 0.003" - 0.047" (0.076mm - 1.2mm) | Thickness of individual wire. Affects strength, open area, and resistance to damage. |

| Aperture Size (Opening) | 0.0033" - 0.097" (0.084mm - 2.46mm) | Clear opening between wires. Dictates particle retention size and airflow. |

| Open Area (%) | Typically 30% - 70% | Percentage of total screen area that is open space. Influences airflow, light transmission, and filtration rate. |

| Tensile Strength | 515 - 620 MPa (Typical) | Maximum stress the material can withstand before breaking. Crucial for security and impact resistance. |

| Standard Roll Widths | 36", 48", 60" (0.91m, 1.22m, 1.52m) | Common industry standard dimensions for ease of fabrication and installation. |

These specifications ensure that the stainless steel window screen selected is optimally suited for its intended environment and function, whether for insect exclusion, ballistic protection, or industrial filtration.

A close-up view revealing the uniform mesh of a stainless steel window screen.

Application Scenarios and Target Industries

The versatility of stainless steel window screen extends across a myriad of industries where robust, long-lasting, and highly functional barriers are indispensable. Its inherent properties make it suitable for environments where other materials would quickly degrade.

- Petrochemical & Chemical Processing: Essential for protecting sensitive equipment and personnel from airborne contaminants, sparks, and corrosive elements. AISI 316 stainless steel window screen provides superior resistance to chemical attack.

- Metallurgy & Mining: Used in ventilation systems, dust control, and protective screens for machinery in harsh, abrasive environments where durability is paramount.

- Water Treatment & Wastewater Management: Employed as coarse filtration media, trash screens, and debris barriers in intake structures and clarifiers, resisting biofouling and corrosion from treated and untreated water.

- Food & Beverage Processing: Vital for insect exclusion and hygienic filtration, where non-corrosive and easily cleanable surfaces are mandated by FDA and HACCP standards. The inert nature of stainless steel prevents material contamination.

- Pharmaceutical & Healthcare: Used in sterile environments for filtered ventilation and pest control, minimizing risk of contamination and adhering to strict air purity requirements.

- Coastal & Marine Structures: Ideal for properties exposed to saltwater spray, where superior corrosion resistance prevents premature degradation seen in other metal window screen options.

- High-Security Facilities: Heavy gauge metal window screen made from stainless steel offers enhanced security against forced entry, vandalism, and projectile impact, serving as effective security screens.

- Commercial & Residential High-Rises: Provides robust insect screens for windows that withstand high winds, UV radiation, and general wear and tear, maintaining aesthetic appeal and function over decades.

The strategic deployment of these screens leads to significant operational benefits, including reduced maintenance cycles, enhanced safety, and compliance with industry-specific regulations.

A commercial building integrating stainless steel window screen for robust protection and airflow.

Technical Advantages and Performance Metrics

The technical superiority of stainless steel window screen stems from the inherent properties of the material and the precision of its manufacturing. These advantages translate directly into long-term performance and cost savings for end-users.

- Exceptional Corrosion Resistance: Stainless steel, particularly AISI 316, forms a passive chromium oxide layer that protects against rust, pitting, and crevice corrosion, even in highly aggressive chemical or saltwater environments. This far surpasses the resistance of standard aluminum window screen.

- High Tensile Strength & Durability: With tensile strengths often exceeding 500 MPa, stainless steel window screen offers superior resistance to tearing, stretching, and impact damage. This makes it ideal for security applications and areas prone to physical stress.

- UV Stability: Unlike polymer-based insect screens for windows, stainless steel is impervious to UV degradation, ensuring it retains its structural integrity and aesthetic appearance over decades without becoming brittle or discolored.

- Fire Resistance: Stainless steel is non-combustible, offering a critical safety advantage in industrial and high-rise commercial buildings, acting as a fire-resistant barrier.

- Thermal Stability: Maintains structural integrity across a wide range of temperatures, from extreme cold to high heat, without warping or degrading.

- Low Maintenance: Its smooth, non-porous surface resists dirt accumulation and is easy to clean, reducing the need for frequent maintenance and cleaning agents.

- Aesthetic Appeal: The metallic luster and fine mesh weave provide a modern, sleek appearance that blends seamlessly with contemporary architecture, often offering better visibility compared to darker, thicker conventional screens.

- Recyclability: Stainless steel is 100% recyclable, contributing to sustainable building practices and reducing environmental impact.

These combined technical advantages ensure that investment in a metal window screen mesh made from stainless steel yields a superior return through extended service life, reduced operational costs, and enhanced safety.

Demonstrating the robust tensile strength of a stainless steel window screen.

Vendor Comparison: Stainless Steel vs. Aluminum Window Screens

When selecting a durable window screen, businesses often weigh the merits of stainless steel window screen against aluminum window screen. While both are metal window screen options, their performance profiles, costs, and ideal applications differ significantly. This comparison highlights key considerations for procurement specialists and engineers.

Product Comparison Table: Stainless Steel vs. Aluminum Window Screens

| Feature/Parameter | Stainless Steel Window Screen (AISI 304/316) | Aluminum Window Screen |

|---|---|---|

| Corrosion Resistance | Excellent (especially 316 in marine/chemical) | Good (oxidizes to form protective layer, but vulnerable to alkalis/chlorides) |

| Tensile Strength | Superior (High impact & tear resistance) | Moderate (Prone to denting/tearing under stress) |

| Weight | Heavier | Lighter |

| Cost (Initial) | Higher | Lower |

| Service Life | 20+ years (with proper maintenance) | 5-15 years (depending on environment) |

| Maintenance | Very Low | Low to Moderate (can oxidize, discolor) |

| Security Rating | High (security screens) | Low to Moderate |

| Aesthetic | Modern, professional, high visibility | Standard, can dull over time |

While aluminum window screen offers a lower initial cost, the long-term total cost of ownership (TCO) often favors stainless steel window screen due to its extended service life, minimal maintenance requirements, and superior performance in challenging environments. For critical B2B applications, the robust nature and reliability of stainless steel typically outweigh the initial price difference.

Side-by-side view comparing the visual integrity of a stainless steel window screen with a conventional screen.

Customized Solutions for Specific Project Requirements

Recognizing that standard products may not always meet the unique demands of every industrial or commercial project, leading manufacturers offer highly customized solutions for stainless steel window screen. This bespoke approach ensures optimal performance, integration, and cost-effectiveness for specialized applications.

Customization options include:

- Non-Standard Dimensions: Production of rolls or cut-to-size sheets beyond typical widths and lengths to minimize waste and simplify installation for large-scale projects or unusual openings.

- Specific Mesh Counts & Wire Diameters: Fine-tuning the mesh count (e.g., 200 x 200 for micro-filtration) and wire diameter to achieve precise aperture sizes, optimal open area percentages, and specific strength requirements for filtration, screening, or security applications.

- Specialized Alloys: Utilizing other stainless steel grades (e.g., Duplex, Super Duplex) for extreme environments requiring even greater corrosion resistance or strength beyond what standard AISI 304/316 offers.

- Surface Treatments & Coatings: Application of specialized coatings (e.g., PTFE for non-stick properties, black epoxy for enhanced stealth or visibility reduction) or passivation treatments to further enhance specific performance characteristics.

- Fabrication & Edging: Custom fabrication services including cutting, welding, bending, and specialized edging (e.g., seamed edges, crimped borders) to create ready-to-install components or filters.

- Prototype Development: Collaborative engineering and rapid prototyping for novel applications or highly experimental requirements, ensuring the final metal window screen mesh meets stringent performance criteria.

Engaging with manufacturers who possess in-house engineering and production capabilities for customized solutions can lead to significant efficiencies and performance gains, ensuring that the chosen stainless steel window screen is not just a component, but an optimized system element.

Application Case Studies

Real-world applications demonstrate the tangible benefits of deploying high-quality stainless steel window screen. Here are examples showcasing its superior performance:

- Case Study 1: Coastal Research Facility – Corrosion Resistance

A prominent marine research institute situated on the Pacific coast faced persistent issues with rapid degradation of conventional aluminum window screen due to constant exposure to salt spray. Within 3-5 years, screens would show significant pitting, discoloration, and structural weakening. Following a strategic upgrade to AISI 316 stainless steel window screen (18x16 mesh, 0.011" wire diameter), the facility has reported virtually no visible corrosion or structural compromise over a 10-year period. This has resulted in a 60% reduction in screen replacement costs and significantly improved integrity of their insect screens for windows.

- Case Study 2: High-Security Data Center – Physical Security

A large-scale data center required advanced physical security measures for its vulnerable window openings without impeding airflow. Traditional security bars were deemed aesthetically unacceptable and difficult to integrate with existing fire safety systems. By implementing a heavy-gauge 12x12 mesh metal window screen of AISI 304 stainless steel with a 0.028" wire diameter, the facility achieved superior resistance to forced entry attempts and ballistic impacts, tested to industry security standards. The solution provided critical deterrence while maintaining efficient cooling system ventilation.

- Case Study 3: Pharmaceutical Manufacturing Plant – Contaminant Control

A pharmaceutical cleanroom facility encountered challenges with airborne particulate ingress through standard insect screens, despite HVAC filtration. Switching to an ultra-fine 50x50 mesh stainless steel window screen (0.009" wire diameter) drastically reduced the passage of micro-particulates and flying insects, contributing to stricter adherence to ISO 14644-1 cleanroom standards. The non-shedding, inert properties of the stainless steel were crucial for preventing secondary contamination risks.

A successful installation of stainless steel window screen in an industrial setting, providing long-term protection.

Commitment to : Authoritativeness and Trustworthiness

Our commitment to Expertise, Experience, Authoritativeness, and Trustworthiness () is foundational to our operations and product offerings, particularly concerning our high-quality stainless steel window screen solutions. We uphold stringent standards across all facets of our business.

Certifications & Quality Assurance

We operate under an ISO 9001 certified quality management system, ensuring that every stage of the manufacturing process, from raw material procurement to final inspection of our metal window screen mesh, meets rigorous international standards. Our materials conform to ASTM (American Society for Testing and Materials) and EN (European Standards) specifications, verified through independent laboratory testing. We regularly supply material certificates of conformity (MTCs) with all shipments, detailing chemical composition and mechanical properties.

Clientele & Experience

With over 25 years of experience in metal mesh fabrication, we have partnered with leading EPC (Engineering, Procurement, and Construction) firms, government agencies, and Fortune 500 companies across diverse sectors including petrochemical, marine, and commercial construction. Our long-standing relationships are built on consistent delivery of high-performance products and reliable service.

Visual representation of our commitment to quality in stainless steel window screen production.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a custom stainless steel window screen order?

- A: Standard product orders typically ship within 5-7 business days. Custom orders, depending on complexity and quantity, generally have a lead time of 2-4 weeks from final design approval. We provide precise lead times with each quote.

- Q: What warranty is offered on your stainless steel window screen products?

- A: We offer a comprehensive 10-year warranty against manufacturing defects and premature corrosion under normal operating conditions for our stainless steel products. Specific terms are outlined in our product documentation.

- Q: How do you handle after-sales support and technical inquiries?

- A: Our dedicated technical support team is available via phone and email from 8 AM to 5 PM EST, Monday through Friday. We offer prompt assistance for installation guidance, maintenance advice, and troubleshooting. On-site technical support can be arranged for complex industrial projects.

- Q: Can your insect screens for windows meet specific regulatory standards?

- A: Yes, our products are often specified to meet various industry standards, including those for food contact (FDA-compliant grades), pharmaceutical cleanroom requirements, and security ratings (e.g., impact resistance). Please specify your required standards when requesting a quote.

Conclusion

The selection of appropriate screening materials is a critical decision impacting the operational efficiency, safety, and longevity of industrial, commercial, and even high-end residential infrastructures. The stainless steel window screen stands as a paramount solution, offering unmatched durability, superior corrosion resistance, and robust security features that far exceed the capabilities of conventional alternatives. Its technical advantages, substantiated by rigorous manufacturing processes and adherence to international standards, position it as a strategic investment for any entity seeking to optimize its protective barriers.

By understanding the comprehensive benefits, technical specifications, and diverse application potential of stainless steel window screen, B2B decision-makers can make informed choices that yield long-term value, reduce maintenance costs, and enhance overall operational integrity. The ongoing innovation in metal window screen mesh technology, coupled with the proven track record of stainless steel, ensures that this material will continue to be the benchmark for high-performance screening solutions across the globe.

References

- ASM International. (2001). ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

- ASTM International. (Latest Edition). ASTM E2016-11: Standard Specification for Industrial Woven Wire Cloth. ASTM International.

- European Committee for Standardization. (Latest Edition). EN 10088-1: Stainless steels - Part 1: List of stainless steels. CEN.

- International Organization for Standardization. (Latest Edition). ISO 9001: Quality management systems – Requirements. ISO.

- NACE International. (Latest Edition). NACE MR0175/ISO 15156: Petroleum and natural gas industries—Materials for use in H2S-containing environments in oil and gas production. NACE International.

Latest News

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

-

Ferrotech Grating: Durable Solutions for Modern Industry

NewsNov.17,2025

-

Trusted Aluminum Grating Manufacturers | Durable & Light

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA