Sep . 15, 2025 09:07 Back to list

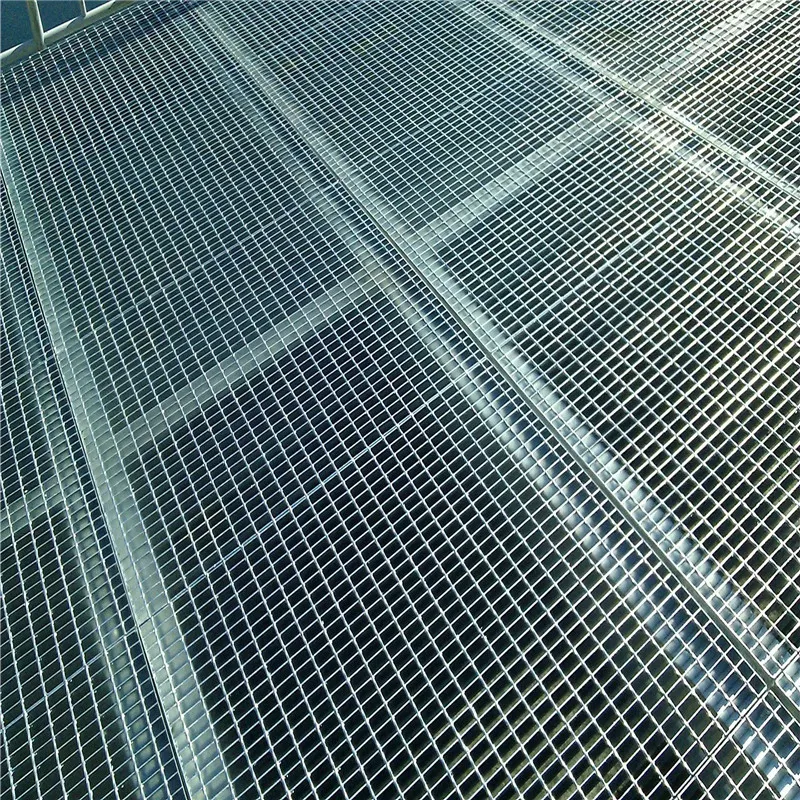

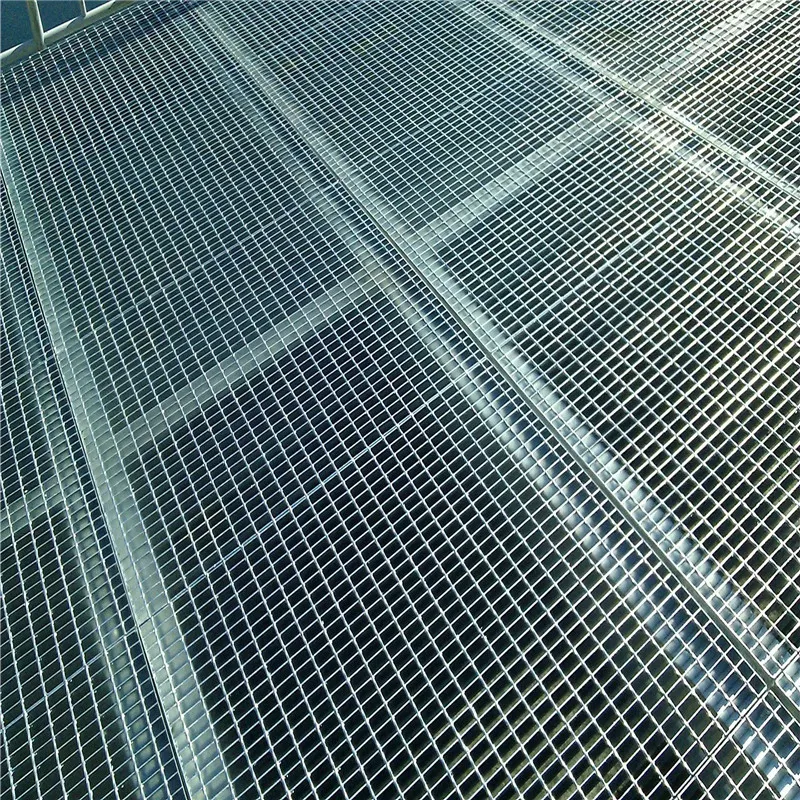

Durable Galvanized Steel Grating Welded for Platform Walkways

Advancing Industrial Infrastructure with High-Performance Steel Grating

In the realm of industrial and civil engineering, reliable and robust platform materials are paramount for ensuring safety, efficiency, and longevity. The demand for durable, corrosion-resistant, and high load-bearing solutions has led to the widespread adoption of advanced steel grating products. Among these, the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway stands out as a leading solution, offering exceptional structural integrity and environmental resilience. This comprehensive overview delves into the critical aspects of this specialized product, exploring its manufacturing intricacies, technical advantages, diverse applications, and the industry landscape it navigates.

Current industry trends emphasize sustainability, extended service life, and reduced maintenance costs. Hot-dip galvanized steel grating directly addresses these imperatives by providing superior corrosion protection, significantly outperforming traditional painted or untreated steel. The global market for industrial gratings is projected to grow steadily, driven by investments in infrastructure, petrochemical facilities, power plants, and wastewater treatment plants. Engineers and procurement professionals are increasingly prioritizing products that comply with stringent international standards and offer verifiable performance data.

Detailed Manufacturing Process of Galvanized Steel Grating

The production of a high-quality Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway involves a meticulous multi-stage process designed to ensure structural integrity, precise dimensions, and optimal surface protection. This process adheres to industry-leading standards such as ISO 9001 for quality management and ASTM A123 for zinc coating.

Process Flow:

1. Material Selection

Utilizing high-grade carbon steel (e.g., Q235, SS400) for bearing bars and cross bars, ensuring mechanical strength and weldability.

2. Cutting and Notching

Precision cutting of bearing bars (40x3mm) and cross bars to specified lengths. Notching may be performed for interlock designs.

3. Welding (Resistance Welding)

Bearing bars are arranged at 295mm spacing, and cross bars are press-welded at 690mm centers under high heat and pressure, forming a robust grid structure.

4. Edge Banding

Perimeter bars are welded to the edges for enhanced stability, load distribution, and a finished appearance, preventing distortion.

5. Surface Preparation (Cleaning)

The fabricated steel grating undergoes degreasing, pickling (acid bathing to remove rust and mill scale), and fluxing to prepare the surface for galvanization.

6. Hot-Dip Galvanization

Immersion into a molten zinc bath (typically 450°C) creates a metallurgically bonded, uniform, and sacrificial zinc coating, providing superior corrosion resistance. This process meets ASTM A123 standards for coating thickness.

7. Inspection and Finishing

Post-galvanization inspection checks for coating uniformity, adherence, dimensional accuracy, and absence of defects. Any sharp edges or zinc drips are removed.

The service life of a hot-dip galvanized steel grating is significantly extended due to the inherent properties of the zinc coating, often exceeding 20-30 years even in harsh industrial environments. This corrosion resistance is particularly advantageous in target industries such as petrochemical, metallurgy, power generation, and water supply & drainage, where exposure to corrosive chemicals, high humidity, and extreme temperatures is common. The robust construction ensures high load-bearing capacity and structural stability, making it ideal for platform walkways, mezzanines, and trench covers. The energy-saving aspect comes from reduced need for frequent replacements and maintenance, leading to lower operational costs over the product's lifespan.

Technical Specifications and Parameters

Understanding the precise technical specifications of a Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway is crucial for engineers and project managers to ensure optimal performance and safety. The specified dimensions directly impact load distribution, deflection, and overall structural integrity.

Product Specification Table:

| Parameter | Specification | Standard |

|---|---|---|

| Product Type | Welded Steel Bar Grating | ISO 1461, ANSI/NAAMM MBG 531 |

| Bearing Bar Dimension | 40mm (Height) × 3mm (Thickness) | ASTM A36/A283M |

| Bearing Bar Pitch | 30mm (standard) or customized | YBT 4001.1-2007 |

| Cross Bar Pitch | 50mm or 100mm (standard) | YBT 4001.1-2007 |

| Panel Dimensions | 295mm × 690mm (Standard, custom available) | Internal QA, project-specific |

| Material Grade | Q235 Mild Steel (or equivalent SS400) | GB/T 700, EN 10025 |

| Surface Treatment | Hot-Dip Galvanized | ASTM A123, ISO 1461 |

| Zinc Coating Thickness | ≥65 µm (typical for 3mm thickness) | ASTM A123, ISO 1461 |

| Load Bearing Capacity | Up to 2.5 kN/m² for typical spans (dependent on specific span/support) | AS 1657, BS 4592 |

| Anti-slip Surface | Plain or Serrated | Customer Specified |

These specifications underline the product's suitability for demanding industrial environments. The 40mm x 3mm bearing bar configuration offers an excellent balance of strength-to-weight ratio, ensuring minimal deflection under anticipated loads while maintaining manageable panel weight for installation. The hot-dip galvanization process, adhering to ASTM A123, ensures a robust zinc coating that provides cathodic protection against corrosion, significantly extending the grating's functional life compared to other surface treatments.

Diverse Application Scenarios

The versatility and durability of Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway make it an indispensable component across a multitude of industrial and commercial applications. Its robust design is particularly suited for environments where safety, drainage, and load-bearing capacity are critical.

- Industrial Platform Walkways: Essential in factories, power plants, and processing facilities for safe access over machinery, pipes, and elevated areas. The open mesh design allows for excellent light and air penetration while preventing accumulation of debris.

- Mezzanines and Catwalks: Provides robust and non-slip surfaces for elevated structures, optimizing vertical space in warehouses and manufacturing units.

- Trench and Drain Covers: Ideal for covering open trenches in chemical plants, wastewater treatment facilities, and public areas. The 295x690mm panel size offers a practical module for various trench widths, ensuring effective drainage and preventing falls.

- Stair Treads: When custom-fabricated with nosings and end plates, these gratings form durable and safe stair treads for industrial access.

- Refineries and Petrochemical Plants: The superior corrosion resistance of hot-dip galvanization is crucial in these highly corrosive environments, ensuring long-term structural integrity for platforms, service areas, and emergency exits.

- Mining and Mineral Processing: Withstands heavy loads and abrasive conditions, providing safe access in challenging terrain and processing areas.

- Marine and Offshore Applications: Although additional coatings might be needed for extreme marine conditions, the base galvanization offers substantial protection against saltwater spray and humidity for platforms, gangways, and engine room flooring.

In all these scenarios, the specific dimensions and galvanized finish contribute directly to enhanced worker safety, operational efficiency, and reduced maintenance burdens. The robust welding ensures uniform load distribution, minimizing localized stress points and extending the overall service life of the installation.

Key Technical Advantages

The inherent design and material properties of Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway confer several significant technical advantages that are critical for long-term industrial performance.

-

Superior Corrosion Resistance:

The hot-dip galvanization process creates a metallurgical bond between steel and zinc, forming a highly durable, abrasion-resistant barrier that protects against rust and corrosion. This cathodic protection self-heals minor scratches, ensuring a significantly longer service life than painted or electro-galvanized alternatives, especially in humid or chemical-laden environments. This contributes to reduced maintenance cycles and lower lifecycle costs.

-

High Load-Bearing Capacity:

With 40x3mm bearing bars, the grating is engineered to support significant static and dynamic loads. The precise welding of cross bars at 690mm intervals ensures uniform load distribution across the panel, preventing localized stress and enhancing overall structural stability. This makes it ideal for heavy foot traffic and light vehicular loads.

-

Excellent Safety Features:

The open mesh design prevents the accumulation of water, oil, and debris, significantly reducing slip hazards. Options for serrated bearing bars further enhance anti-slip properties, critical in industrial settings. The uniform grid also ensures excellent light and air permeability, improving visibility and ventilation in enclosed spaces.

-

Ease of Installation and Maintenance:

Standardized panel sizes (e.g., 295x690mm) facilitate modular installation. Grating clips or bolted connections allow for quick and secure fastening. The galvanized surface requires minimal maintenance; routine cleaning is often sufficient, translating into considerable operational cost savings over its extensive lifespan.

Vendor Comparison and Customization

When selecting a supplier for Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway, discerning buyers consider more than just the base product. Factors such as manufacturing expertise, quality certifications, customization capabilities, and post-sales support significantly influence the total cost of ownership and project success.

Vendor Comparison Matrix:

| Feature/Service | Leading Manufacturer (e.g., Chengsen) | Standard Supplier |

|---|---|---|

| Quality Certifications | ISO 9001:2015, ASTM A123, CE | Basic quality assurance, sometimes no external certification |

| Customization Options | Full range: bespoke dimensions, cut-outs, special finishes, various bearing bar/cross bar spacings, access stair fabrication | Limited to standard sizes; minimal modification capabilities |

| Engineering Support | Dedicated engineering team for design consultation, load calculations, shop drawings | Basic product information only |

| Lead Time & Logistics | Optimized production lines, global logistics partnerships, timely delivery commitments | Variable lead times, limited shipping options |

| Warranty & After-Sales | Comprehensive warranty (e.g., 5-10 years on manufacturing defects/galvanization), responsive support | Limited or no explicit warranty, basic customer service |

| Market Reputation | Established track record, positive customer testimonials, numerous completed projects | Newer or less established, fewer verifiable references |

Customized Solutions:

While standard 295x690mm panels are efficient for many applications, complex industrial layouts often require tailor-made solutions. Leading manufacturers offer extensive customization capabilities including:

- Non-standard panel dimensions: Fabrication to exact length and width requirements to minimize on-site cutting and waste.

- Cut-outs and openings: Precision cut-outs for pipes, columns, machinery, and access points, pre-fabricated for seamless integration.

- Special bearing bar and cross bar spacings: Adjusting mesh sizes to meet specific load requirements or prevent small tools from falling through.

- Surface options: Plain, serrated (anti-slip), or specific anti-corrosive coatings for highly aggressive environments.

- Attachment options: Design for specific fixing methods, including saddle clips, G-clips, or welded-on lugs.

Engaging with a vendor that prioritizes comprehensive engineering support and flexible manufacturing allows for optimized designs, faster project completion, and ensures that the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway perfectly integrates into the project's unique demands.

Application Case Studies and Customer Feedback

Real-world application validates the performance and reliability of industrial products. The Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway has been successfully deployed in numerous demanding projects, demonstrating its value through practical results and positive client experiences.

Case Study 1: Petrochemical Plant Walkways

Client: Major Middle Eastern Oil & Gas Corporation

Challenge: Existing grating on elevated platforms showed rapid corrosion due to exposure to aggressive chemical fumes and high humidity, leading to frequent replacement and safety concerns.

Solution: Implementation of custom-sized Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway panels across critical access areas. The panels were pre-fabricated with cut-outs for pipework and structural elements.

Outcome: After 5 years, the galvanized grating shows minimal signs of corrosion, significantly outperforming previous materials. Worker safety has improved due to the reliable anti-slip surface. The client reported a 70% reduction in maintenance frequency for platform flooring, leading to substantial operational savings. Third-party testing confirmed adherence to specified zinc coating thickness (averaging 80 µm).

Case Study 2: Wastewater Treatment Facility Trench Covers

Client: Municipal Water Authority, North America

Challenge: Existing concrete trench covers were heavy, prone to cracking, and difficult to remove for maintenance. The environment was highly corrosive due to effluent gases.

Solution: Installation of 295x690mm Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway as trench covers. The lightweight yet strong panels allowed for easy removal for access to underlying equipment.

Outcome: The open mesh design provided superior ventilation, reducing gas buildup, while the galvanization offered excellent resistance to the corrosive atmosphere. Facility operators noted a significant improvement in ease of access and worker safety. The modular design streamlined installation across varying trench lengths, reducing installation time by 40%.

Customer Feedback:

"The galvanized grating supplied for our new power plant expansion exceeded our expectations. The quality of welding was impeccable, and the galvanization held up perfectly during installation. Their engineering team was instrumental in providing detailed shop drawings for our complex layout." - Project Manager, Power Generation Sector.

"We've been using Chengsen's galvanized gratings for over a decade in our mining operations. The 40x3mm bearing bars provide the rigidity needed for our heavy-duty platforms, and the hot-dip galvanization withstands the abrasive and wet conditions without issue. A truly reliable product." - Procurement Head, Mining Corporation.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for a standard order of Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway?

A1: For standard sizes and quantities (e.g., up to 500 panels), our typical lead time is 2-3 weeks from order confirmation. Larger or highly customized orders may require 4-6 weeks. We maintain robust inventory and efficient production lines to minimize delays. Specific lead times will be provided with your quotation based on project scope.

Q2: What are the warranty commitments for your galvanized steel grating products?

A2: We offer a comprehensive 5-year warranty against manufacturing defects and structural failures under normal use conditions. Our hot-dip galvanization is guaranteed to meet ASTM A123 standards for zinc coating thickness and adhesion, providing long-term corrosion protection. Detailed warranty terms are available upon request.

Q3: How do I determine the correct load-bearing capacity for my application?

A3: Determining load capacity requires considering the span, desired deflection limits, and anticipated uniform or concentrated loads. Our engineering team can provide detailed load tables and perform specific calculations based on your project's parameters and relevant industry standards (e.g., AS 1657, BS 4592). Please provide your span length, loading conditions, and desired safety factors for an accurate assessment.

Q4: Can these gratings be used in highly corrosive marine environments?

A4: Hot-dip galvanization provides excellent protection against general atmospheric corrosion and some marine conditions. However, for extremely harsh, continuously submerged, or highly saline marine environments, additional protective measures such as duplex coating systems (galvanization plus powder coating) or specialized alloy steels might be recommended. We advise consulting with our technical experts for tailored advice on marine applications to ensure optimal longevity.

Q5: What are the options for securing the grating panels?

A5: Our Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway panels can be secured using various methods. Standard saddle clips (M8/M10 bolts), G-clips, or welded-on lugs are common options. The choice depends on the structural steelwork, load requirements, and whether the panels need to be easily removable. We can provide appropriate fastening solutions and guidance for your specific installation.

Logistics, Fulfillment, and Customer Support

Efficient project execution relies not only on product quality but also on seamless logistics and dependable post-sales support. We are committed to providing a streamlined experience for our B2B clients, from order placement to delivery and beyond.

Lead Time & Fulfillment Details:

- Production Capacity: Our advanced manufacturing facility has a monthly capacity of over 1000 tons of steel grating, ensuring efficient handling of large-scale industrial projects.

- Standard Orders: Typically 15-20 business days for fabrication and galvanization, depending on current production queue and volume.

- Custom Orders: Generally 20-30 business days, allowing for design consultation, specialized tooling, and quality assurance for unique specifications.

- Logistics & Shipping: We partner with reliable domestic and international freight forwarders to ensure secure and timely delivery to your project site. Options include FCL (Full Container Load) and LCL (Less than Container Load) for global shipments, or dedicated truck transport for domestic deliveries. All shipments are carefully packed and secured to prevent damage during transit.

Customer Support and Technical Assistance:

- Dedicated Account Managers: Each client is assigned a dedicated account manager to streamline communication and ensure project requirements are fully understood and met.

- Technical Support: Our team of experienced engineers provides pre-sale consultation, technical drawings, load calculations, and installation guidance. We assist with material selection, grating type, surface treatment, and fastening methods.

- After-Sales Service: We offer prompt support for any post-delivery inquiries, installation challenges, or warranty claims. Our goal is to ensure long-term satisfaction and performance of our Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway.

Commitment to Quality and Certifications

Our unwavering commitment to quality is foundational to our operations. Every stage of manufacturing, from raw material sourcing to final inspection, is governed by stringent quality control protocols, ensuring that each Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway product meets and exceeds client expectations and international standards.

Certifications and Compliance:

- ISO 9001:2015 Certified: Our Quality Management System is internationally recognized, ensuring consistent product quality and process efficiency.

- ASTM A123 / A123M-17: Compliance with Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products, guaranteeing coating performance.

- CE Marking: Demonstrating conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- ANSI/NAAMM MBG 531-09: Adherence to the Metal Bar Grating Manual, providing standards for design, fabrication, and installation.

Internal Quality Control:

Beyond external certifications, our internal QA/QC procedures include:

- Raw material verification (mill certificates)

- Dimensional accuracy checks during cutting and welding

- Weld integrity testing (visual, occasionally destructive for batch samples)

- Galvanization thickness and adhesion tests (e.g., magnetic induction or eddy current methods, Preece test)

- Final visual inspection for surface finish, burrs, and overall conformity

Conclusion

The Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway represents a critical investment for any industrial or commercial project demanding robust, durable, and corrosion-resistant flooring solutions. Its superior manufacturing process, adherence to international quality standards, and proven performance in diverse application scenarios underscore its value proposition. By offering both standard and highly customized options, coupled with comprehensive technical support and reliable logistics, we ensure that clients receive a product that not only meets but exceeds their stringent requirements for safety, longevity, and operational efficiency. Choosing a certified and experienced manufacturer ensures a long-term, cost-effective solution for your platform and walkway needs.

References

- American Society for Testing and Materials (ASTM). "ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products."

- International Organization for Standardization (ISO). "ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods."

- National Association of Architectural Metal Manufacturers (NAAMM). "Metal Bar Grating Manual (MBG 531-09)."

- Galvanizers Association. "Corrosion Protection: Hot Dip Galvanizing." Available at: www.galvanizing.org.uk

- World Steel Association. "Steel in Infrastructure." Available at: www.worldsteel.org

Latest News

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

-

Ferrotech Grating: Durable Solutions for Modern Industry

NewsNov.17,2025

-

Trusted Aluminum Grating Manufacturers | Durable & Light

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Sep . 08, 2025 16:38 Back to list

Durable Galvanized Steel Grating Welded for Platform Walkways

Advancing Industrial Infrastructure with High-Performance Steel Grating

In the realm of industrial and civil engineering, reliable and robust platform materials are paramount for ensuring safety, efficiency, and longevity. The demand for durable, corrosion-resistant, and high load-bearing solutions has led to the widespread adoption of advanced steel grating products. Among these, the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway stands out as a leading solution, offering exceptional structural integrity and environmental resilience. This comprehensive overview delves into the critical aspects of this specialized product, exploring its manufacturing intricacies, technical advantages, diverse applications, and the industry landscape it navigates.

Current industry trends emphasize sustainability, extended service life, and reduced maintenance costs. Hot-dip galvanized steel grating directly addresses these imperatives by providing superior corrosion protection, significantly outperforming traditional painted or untreated steel. The global market for industrial gratings is projected to grow steadily, driven by investments in infrastructure, petrochemical facilities, power plants, and wastewater treatment plants. Engineers and procurement professionals are increasingly prioritizing products that comply with stringent international standards and offer verifiable performance data.

Detailed Manufacturing Process of Galvanized Steel Grating

The production of a high-quality Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway involves a meticulous multi-stage process designed to ensure structural integrity, precise dimensions, and optimal surface protection. This process adheres to industry-leading standards such as ISO 9001 for quality management and ASTM A123 for zinc coating.

Process Flow:

1. Material Selection

Utilizing high-grade carbon steel (e.g., Q235, SS400) for bearing bars and cross bars, ensuring mechanical strength and weldability.

2. Cutting and Notching

Precision cutting of bearing bars (40x3mm) and cross bars to specified lengths. Notching may be performed for interlock designs.

3. Welding (Resistance Welding)

Bearing bars are arranged at 295mm spacing, and cross bars are press-welded at 690mm centers under high heat and pressure, forming a robust grid structure.

4. Edge Banding

Perimeter bars are welded to the edges for enhanced stability, load distribution, and a finished appearance, preventing distortion.

5. Surface Preparation (Cleaning)

The fabricated steel grating undergoes degreasing, pickling (acid bathing to remove rust and mill scale), and fluxing to prepare the surface for galvanization.

6. Hot-Dip Galvanization

Immersion into a molten zinc bath (typically 450°C) creates a metallurgically bonded, uniform, and sacrificial zinc coating, providing superior corrosion resistance. This process meets ASTM A123 standards for coating thickness.

7. Inspection and Finishing

Post-galvanization inspection checks for coating uniformity, adherence, dimensional accuracy, and absence of defects. Any sharp edges or zinc drips are removed.

The service life of a hot-dip galvanized steel grating is significantly extended due to the inherent properties of the zinc coating, often exceeding 20-30 years even in harsh industrial environments. This corrosion resistance is particularly advantageous in target industries such as petrochemical, metallurgy, power generation, and water supply & drainage, where exposure to corrosive chemicals, high humidity, and extreme temperatures is common. The robust construction ensures high load-bearing capacity and structural stability, making it ideal for platform walkways, mezzanines, and trench covers. The energy-saving aspect comes from reduced need for frequent replacements and maintenance, leading to lower operational costs over the product's lifespan.

Technical Specifications and Parameters

Understanding the precise technical specifications of a Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway is crucial for engineers and project managers to ensure optimal performance and safety. The specified dimensions directly impact load distribution, deflection, and overall structural integrity.

Product Specification Table:

| Parameter | Specification | Standard |

|---|---|---|

| Product Type | Welded Steel Bar Grating | ISO 1461, ANSI/NAAMM MBG 531 |

| Bearing Bar Dimension | 40mm (Height) × 3mm (Thickness) | ASTM A36/A283M |

| Bearing Bar Pitch | 30mm (standard) or customized | YBT 4001.1-2007 |

| Cross Bar Pitch | 50mm or 100mm (standard) | YBT 4001.1-2007 |

| Panel Dimensions | 295mm × 690mm (Standard, custom available) | Internal QA, project-specific |

| Material Grade | Q235 Mild Steel (or equivalent SS400) | GB/T 700, EN 10025 |

| Surface Treatment | Hot-Dip Galvanized | ASTM A123, ISO 1461 |

| Zinc Coating Thickness | ≥65 µm (typical for 3mm thickness) | ASTM A123, ISO 1461 |

| Load Bearing Capacity | Up to 2.5 kN/m² for typical spans (dependent on specific span/support) | AS 1657, BS 4592 |

| Anti-slip Surface | Plain or Serrated | Customer Specified |

These specifications underline the product's suitability for demanding industrial environments. The 40mm x 3mm bearing bar configuration offers an excellent balance of strength-to-weight ratio, ensuring minimal deflection under anticipated loads while maintaining manageable panel weight for installation. The hot-dip galvanization process, adhering to ASTM A123, ensures a robust zinc coating that provides cathodic protection against corrosion, significantly extending the grating's functional life compared to other surface treatments.

Diverse Application Scenarios

The versatility and durability of Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway make it an indispensable component across a multitude of industrial and commercial applications. Its robust design is particularly suited for environments where safety, drainage, and load-bearing capacity are critical.

- Industrial Platform Walkways: Essential in factories, power plants, and processing facilities for safe access over machinery, pipes, and elevated areas. The open mesh design allows for excellent light and air penetration while preventing accumulation of debris.

- Mezzanines and Catwalks: Provides robust and non-slip surfaces for elevated structures, optimizing vertical space in warehouses and manufacturing units.

- Trench and Drain Covers: Ideal for covering open trenches in chemical plants, wastewater treatment facilities, and public areas. The 295x690mm panel size offers a practical module for various trench widths, ensuring effective drainage and preventing falls.

- Stair Treads: When custom-fabricated with nosings and end plates, these gratings form durable and safe stair treads for industrial access.

- Refineries and Petrochemical Plants: The superior corrosion resistance of hot-dip galvanization is crucial in these highly corrosive environments, ensuring long-term structural integrity for platforms, service areas, and emergency exits.

- Mining and Mineral Processing: Withstands heavy loads and abrasive conditions, providing safe access in challenging terrain and processing areas.

- Marine and Offshore Applications: Although additional coatings might be needed for extreme marine conditions, the base galvanization offers substantial protection against saltwater spray and humidity for platforms, gangways, and engine room flooring.

In all these scenarios, the specific dimensions and galvanized finish contribute directly to enhanced worker safety, operational efficiency, and reduced maintenance burdens. The robust welding ensures uniform load distribution, minimizing localized stress points and extending the overall service life of the installation.

Key Technical Advantages

The inherent design and material properties of Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway confer several significant technical advantages that are critical for long-term industrial performance.

-

Superior Corrosion Resistance:

The hot-dip galvanization process creates a metallurgical bond between steel and zinc, forming a highly durable, abrasion-resistant barrier that protects against rust and corrosion. This cathodic protection self-heals minor scratches, ensuring a significantly longer service life than painted or electro-galvanized alternatives, especially in humid or chemical-laden environments. This contributes to reduced maintenance cycles and lower lifecycle costs.

-

High Load-Bearing Capacity:

With 40x3mm bearing bars, the grating is engineered to support significant static and dynamic loads. The precise welding of cross bars at 690mm intervals ensures uniform load distribution across the panel, preventing localized stress and enhancing overall structural stability. This makes it ideal for heavy foot traffic and light vehicular loads.

-

Excellent Safety Features:

The open mesh design prevents the accumulation of water, oil, and debris, significantly reducing slip hazards. Options for serrated bearing bars further enhance anti-slip properties, critical in industrial settings. The uniform grid also ensures excellent light and air permeability, improving visibility and ventilation in enclosed spaces.

-

Ease of Installation and Maintenance:

Standardized panel sizes (e.g., 295x690mm) facilitate modular installation. Grating clips or bolted connections allow for quick and secure fastening. The galvanized surface requires minimal maintenance; routine cleaning is often sufficient, translating into considerable operational cost savings over its extensive lifespan.

Vendor Comparison and Customization

When selecting a supplier for Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway, discerning buyers consider more than just the base product. Factors such as manufacturing expertise, quality certifications, customization capabilities, and post-sales support significantly influence the total cost of ownership and project success.

Vendor Comparison Matrix:

| Feature/Service | Leading Manufacturer (e.g., Chengsen) | Standard Supplier |

|---|---|---|

| Quality Certifications | ISO 9001:2015, ASTM A123, CE | Basic quality assurance, sometimes no external certification |

| Customization Options | Full range: bespoke dimensions, cut-outs, special finishes, various bearing bar/cross bar spacings, access stair fabrication | Limited to standard sizes; minimal modification capabilities |

| Engineering Support | Dedicated engineering team for design consultation, load calculations, shop drawings | Basic product information only |

| Lead Time & Logistics | Optimized production lines, global logistics partnerships, timely delivery commitments | Variable lead times, limited shipping options |

| Warranty & After-Sales | Comprehensive warranty (e.g., 5-10 years on manufacturing defects/galvanization), responsive support | Limited or no explicit warranty, basic customer service |

| Market Reputation | Established track record, positive customer testimonials, numerous completed projects | Newer or less established, fewer verifiable references |

Customized Solutions:

While standard 295x690mm panels are efficient for many applications, complex industrial layouts often require tailor-made solutions. Leading manufacturers offer extensive customization capabilities including:

- Non-standard panel dimensions: Fabrication to exact length and width requirements to minimize on-site cutting and waste.

- Cut-outs and openings: Precision cut-outs for pipes, columns, machinery, and access points, pre-fabricated for seamless integration.

- Special bearing bar and cross bar spacings: Adjusting mesh sizes to meet specific load requirements or prevent small tools from falling through.

- Surface options: Plain, serrated (anti-slip), or specific anti-corrosive coatings for highly aggressive environments.

- Attachment options: Design for specific fixing methods, including saddle clips, G-clips, or welded-on lugs.

Engaging with a vendor that prioritizes comprehensive engineering support and flexible manufacturing allows for optimized designs, faster project completion, and ensures that the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway perfectly integrates into the project's unique demands.

Application Case Studies and Customer Feedback

Real-world application validates the performance and reliability of industrial products. The Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway has been successfully deployed in numerous demanding projects, demonstrating its value through practical results and positive client experiences.

Case Study 1: Petrochemical Plant Walkways

Client: Major Middle Eastern Oil & Gas Corporation

Challenge: Existing grating on elevated platforms showed rapid corrosion due to exposure to aggressive chemical fumes and high humidity, leading to frequent replacement and safety concerns.

Solution: Implementation of custom-sized Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway panels across critical access areas. The panels were pre-fabricated with cut-outs for pipework and structural elements.

Outcome: After 5 years, the galvanized grating shows minimal signs of corrosion, significantly outperforming previous materials. Worker safety has improved due to the reliable anti-slip surface. The client reported a 70% reduction in maintenance frequency for platform flooring, leading to substantial operational savings. Third-party testing confirmed adherence to specified zinc coating thickness (averaging 80 µm).

Case Study 2: Wastewater Treatment Facility Trench Covers

Client: Municipal Water Authority, North America

Challenge: Existing concrete trench covers were heavy, prone to cracking, and difficult to remove for maintenance. The environment was highly corrosive due to effluent gases.

Solution: Installation of 295x690mm Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway as trench covers. The lightweight yet strong panels allowed for easy removal for access to underlying equipment.

Outcome: The open mesh design provided superior ventilation, reducing gas buildup, while the galvanization offered excellent resistance to the corrosive atmosphere. Facility operators noted a significant improvement in ease of access and worker safety. The modular design streamlined installation across varying trench lengths, reducing installation time by 40%.

Customer Feedback:

"The galvanized grating supplied for our new power plant expansion exceeded our expectations. The quality of welding was impeccable, and the galvanization held up perfectly during installation. Their engineering team was instrumental in providing detailed shop drawings for our complex layout." - Project Manager, Power Generation Sector.

"We've been using Chengsen's galvanized gratings for over a decade in our mining operations. The 40x3mm bearing bars provide the rigidity needed for our heavy-duty platforms, and the hot-dip galvanization withstands the abrasive and wet conditions without issue. A truly reliable product." - Procurement Head, Mining Corporation.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for a standard order of Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway?

A1: For standard sizes and quantities (e.g., up to 500 panels), our typical lead time is 2-3 weeks from order confirmation. Larger or highly customized orders may require 4-6 weeks. We maintain robust inventory and efficient production lines to minimize delays. Specific lead times will be provided with your quotation based on project scope.

Q2: What are the warranty commitments for your galvanized steel grating products?

A2: We offer a comprehensive 5-year warranty against manufacturing defects and structural failures under normal use conditions. Our hot-dip galvanization is guaranteed to meet ASTM A123 standards for zinc coating thickness and adhesion, providing long-term corrosion protection. Detailed warranty terms are available upon request.

Q3: How do I determine the correct load-bearing capacity for my application?

A3: Determining load capacity requires considering the span, desired deflection limits, and anticipated uniform or concentrated loads. Our engineering team can provide detailed load tables and perform specific calculations based on your project's parameters and relevant industry standards (e.g., AS 1657, BS 4592). Please provide your span length, loading conditions, and desired safety factors for an accurate assessment.

Q4: Can these gratings be used in highly corrosive marine environments?

A4: Hot-dip galvanization provides excellent protection against general atmospheric corrosion and some marine conditions. However, for extremely harsh, continuously submerged, or highly saline marine environments, additional protective measures such as duplex coating systems (galvanization plus powder coating) or specialized alloy steels might be recommended. We advise consulting with our technical experts for tailored advice on marine applications to ensure optimal longevity.

Q5: What are the options for securing the grating panels?

A5: Our Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway panels can be secured using various methods. Standard saddle clips (M8/M10 bolts), G-clips, or welded-on lugs are common options. The choice depends on the structural steelwork, load requirements, and whether the panels need to be easily removable. We can provide appropriate fastening solutions and guidance for your specific installation.

Logistics, Fulfillment, and Customer Support

Efficient project execution relies not only on product quality but also on seamless logistics and dependable post-sales support. We are committed to providing a streamlined experience for our B2B clients, from order placement to delivery and beyond.

Lead Time & Fulfillment Details:

- Production Capacity: Our advanced manufacturing facility has a monthly capacity of over 1000 tons of steel grating, ensuring efficient handling of large-scale industrial projects.

- Standard Orders: Typically 15-20 business days for fabrication and galvanization, depending on current production queue and volume.

- Custom Orders: Generally 20-30 business days, allowing for design consultation, specialized tooling, and quality assurance for unique specifications.

- Logistics & Shipping: We partner with reliable domestic and international freight forwarders to ensure secure and timely delivery to your project site. Options include FCL (Full Container Load) and LCL (Less than Container Load) for global shipments, or dedicated truck transport for domestic deliveries. All shipments are carefully packed and secured to prevent damage during transit.

Customer Support and Technical Assistance:

- Dedicated Account Managers: Each client is assigned a dedicated account manager to streamline communication and ensure project requirements are fully understood and met.

- Technical Support: Our team of experienced engineers provides pre-sale consultation, technical drawings, load calculations, and installation guidance. We assist with material selection, grating type, surface treatment, and fastening methods.

- After-Sales Service: We offer prompt support for any post-delivery inquiries, installation challenges, or warranty claims. Our goal is to ensure long-term satisfaction and performance of our Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway.

Commitment to Quality and Certifications

Our unwavering commitment to quality is foundational to our operations. Every stage of manufacturing, from raw material sourcing to final inspection, is governed by stringent quality control protocols, ensuring that each Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway product meets and exceeds client expectations and international standards.

Certifications and Compliance:

- ISO 9001:2015 Certified: Our Quality Management System is internationally recognized, ensuring consistent product quality and process efficiency.

- ASTM A123 / A123M-17: Compliance with Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products, guaranteeing coating performance.

- CE Marking: Demonstrating conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- ANSI/NAAMM MBG 531-09: Adherence to the Metal Bar Grating Manual, providing standards for design, fabrication, and installation.

Internal Quality Control:

Beyond external certifications, our internal QA/QC procedures include:

- Raw material verification (mill certificates)

- Dimensional accuracy checks during cutting and welding

- Weld integrity testing (visual, occasionally destructive for batch samples)

- Galvanization thickness and adhesion tests (e.g., magnetic induction or eddy current methods, Preece test)

- Final visual inspection for surface finish, burrs, and overall conformity

Conclusion

The Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway represents a critical investment for any industrial or commercial project demanding robust, durable, and corrosion-resistant flooring solutions. Its superior manufacturing process, adherence to international quality standards, and proven performance in diverse application scenarios underscore its value proposition. By offering both standard and highly customized options, coupled with comprehensive technical support and reliable logistics, we ensure that clients receive a product that not only meets but exceeds their stringent requirements for safety, longevity, and operational efficiency. Choosing a certified and experienced manufacturer ensures a long-term, cost-effective solution for your platform and walkway needs.

References

- American Society for Testing and Materials (ASTM). "ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products."

- International Organization for Standardization (ISO). "ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods."

- National Association of Architectural Metal Manufacturers (NAAMM). "Metal Bar Grating Manual (MBG 531-09)."

- Galvanizers Association. "Corrosion Protection: Hot Dip Galvanizing." Available at: www.galvanizing.org.uk

- World Steel Association. "Steel in Infrastructure." Available at: www.worldsteel.org

Latest News

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA