Jul . 15, 2025 11:39 Back to list

Drywall Corner Types for Ceilings

When installing or renovating ceilings, selecting the right drywall corner types is critical for achieving a seamless, durable, and professional finish. Drywall corners are prone to damage due to their exposed edges, making protective and reinforcing solutions essential. This article explores four key drywall corner products: galvanised steel stop bead, metal mesh corner bead, drywall corner types, and drywall edge bead types. Each serves a unique purpose in ceiling installations, ensuring structural integrity and aesthetic appeal. As a manufacturer specializing in bulk production of these components, we provide insights into their applications, benefits, and best practices.

Understanding the Role of Galvanised Steel Stop Bead in Ceiling Installations

Galvanised steel stop bead is a cornerstone product for finishing drywall edges where walls meet ceilings. Made from corrosion-resistant steel coated with zinc, this bead is designed to create clean transitions while protecting vulnerable corners from impact and wear. Its rigidity makes it ideal for areas requiring a sharp, straight edge, such as ceiling perimeters or bulkheads.

In ceiling applications, galvanised steel stop bead is installed by embedding it into joint compound along the drywall’s edge. The bead’s flanges sit flush against the drywall, providing a guide for smooth taping and mudding. This product is particularly advantageous in high-traffic or commercial spaces where durability is paramount. Its zinc coating ensures longevity, even in humid environments, making it a reliable choice for kitchens, bathrooms, and industrial settings.

Manufactured in bulk lengths, galvanised steel stop bead is cost-effective for large-scale projects. Contractors appreciate its ease of installation and resistance to warping, which minimizes rework. For ceilings with complex angles, pre-cut or adjustable variants are available to accommodate unique architectural designs.

Benefits of Metal Mesh Corner Bead for Enhanced Durability

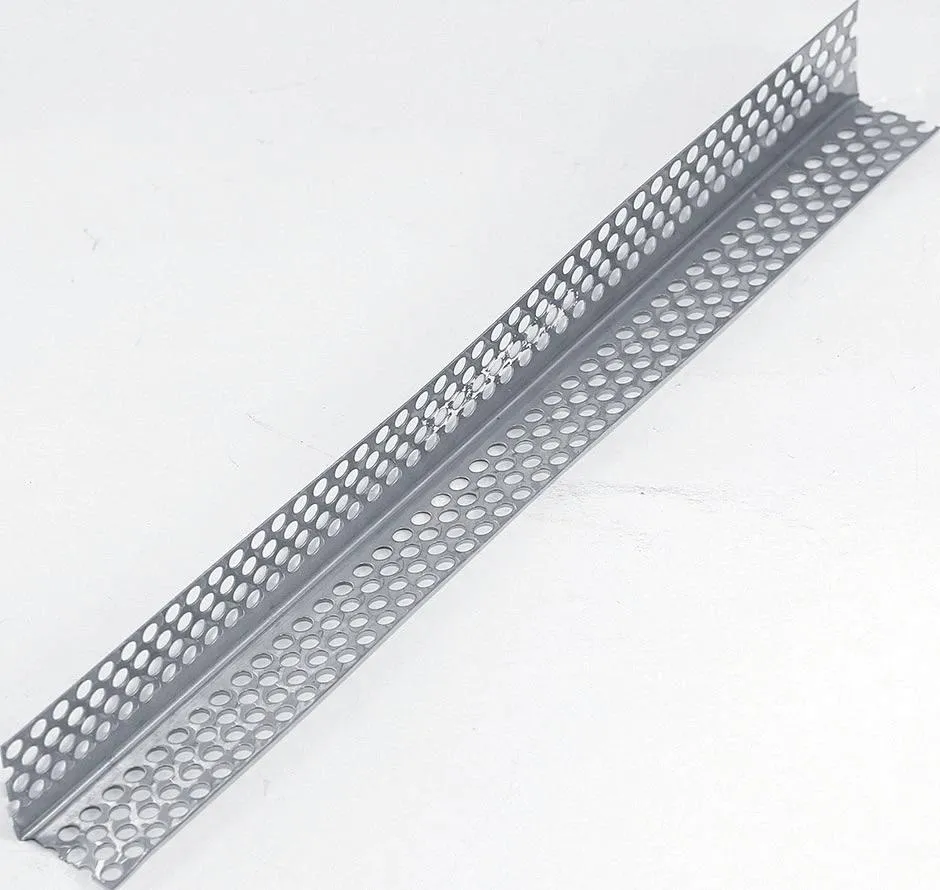

Metal mesh corner bead combines flexibility and strength, making it a versatile option for curved or irregular ceiling corners. Unlike rigid alternatives, this bead features a perforated metal strip embedded in a fiberglass or paper mesh. The design allows it to conform to subtle curves while reinforcing drywall joints.

When applied to ceilings, metal mesh corner bead is secured with joint compound, which seeps through the mesh to create a strong bond. This integration prevents cracking and ensures a smooth finish, even on arched or vaulted ceilings. Its lightweight nature reduces strain on drywall seams, which is critical for overhead installations.

Bulk-produced metal mesh corner bead is a favorite among contractors for retrofit projects or modern designs requiring non-linear profiles. The mesh also provides an excellent base for multiple layers of compound, enabling seamless blending with surrounding surfaces. Additionally, its corrosion-resistant properties make it suitable for both interior and exterior ceiling applications.

Exploring Different Drywall Corner Types for Optimal Performance

The term drywall corner types encompasses a range of products tailored to specific installation needs. Beyond galvanised steel stop bead and metal mesh corner bead, other variants include vinyl-coated beads, paper-faced beads, and tear-away beads. Each type addresses unique challenges in ceiling construction.

Vinyl-coated beads, for instance, offer enhanced resistance to moisture and abrasion, ideal for ceilings in laundry rooms or garages. Paper-faced beads, on the other hand, are lightweight and blend seamlessly with drywall tape, simplifying finishing work. Tear-away beads feature a removable strip that creates crisp edges for decorative finishes like crown molding.

When selecting drywall corner types, consider factors such as ceiling curvature, environmental conditions, and desired aesthetics. Bulk availability ensures consistency across large projects, reducing delays caused by material shortages. Manufacturers often provide custom lengths or pre-formed angles to meet specific architectural requirements.

Selecting the Right Drywall Edge Bead Types for Seamless Finishes

Drywall edge bead types are specialized profiles designed to protect and define the outermost edges of ceiling drywall. These include L-shaped beads, J-shaped beads, and bullnose beads, each serving distinct purposes.

L-shaped beads are the most common, used where two drywall panels meet at a 90-degree angle. J-shaped beads are employed for finishing edges along soffits or drop ceilings, while bullnose beads create rounded edges for a softer look. Drywall edge bead types made from galvanized steel or vinyl ensure longevity and resistance to damage.

In bulk installations, uniformity is key. Pre-fabricated drywall edge bead types streamline the process, allowing contractors to achieve consistent results across vast ceiling areas. Proper installation involves securing the bead with screws or adhesive before applying joint compound, ensuring a flawless transition between surfaces.

FAQs About Drywall Corner Types Products

What is the primary advantage of using galvanised steel stop bead on ceilings?

Galvanised steel stop bead provides unmatched durability and corrosion resistance, making it ideal for high-moisture or high-impact environments. Its rigid structure ensures straight, clean edges along ceiling perimeters.

Can metal mesh corner bead be used for curved ceilings?

Yes, metal mesh corner bead is highly flexible, allowing it to conform to curved or arched ceilings. Its perforated design ensures a strong bond with joint compound, preventing cracks over time.

How do drywall corner types differ from drywall edge bead types?

Drywall corner types protect internal or external corners where two walls or ceilings meet, while drywall edge bead types shield exposed drywall edges, such as those along soffits or bulkheads.

Are drywall edge bead types compatible with all drywall thicknesses?

Most drywall edge bead types are designed to accommodate standard drywall thicknesses (½-inch or ⅝-inch). Custom options are available for non-standard applications.

Why should contractors choose bulk metal mesh corner bead for large projects?

Bulk metal mesh corner bead reduces material costs and ensures consistency across installations. Its lightweight design also simplifies handling and transport.

Choosing the right drywall corner types and drywall edge bead types is essential for achieving durable, aesthetically pleasing ceilings. From galvanised steel stop bead to metal mesh corner bead, each product offers unique benefits tailored to specific installation requirements. As a manufacturer specializing in bulk production, we ensure that contractors have access to high-quality materials that streamline workflows and deliver long-lasting results. By understanding the role of each component, professionals can optimize their ceiling projects for both form and function.

Latest News

-

Heavy Duty Yard Gully - Durable Industrial Drainage Solutions for Harsh Environments

NewsNov.24,2025

-

Everything You Need to Know About In Grating: Applications, Benefits & Trends

NewsNov.24,2025

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA