Sep . 02, 2025 09:38 Back to list

Aluminum Grating for Material Handling Conveyors

Material handling conveyors are the circulatory system of modern industry, transporting raw materials, components, and finished products through factories, warehouses, ports, and processing plants. Their efficiency, reliability, and safety are paramount. One critical component often overlooked is the walking surface or support structure itself – the grating. While steel has long been dominant, aluminum grating is rapidly emerging as the superior choice for countless conveyor applications, offering a compelling blend of strength, lightness, and resilience that revolutionizes performance and longevity.

The shift towards aluminum grating isn't merely a trend; it's a strategic response to the demands of modern, efficient operations. Aluminum’s inherent properties – exceptional strength-to-weight ratio, outstanding corrosion resistance, non-sparking nature, and non-magnetic characteristics – make it uniquely suited for the dynamic, often harsh environments surrounding conveyors. From food and pharmaceutical plants demanding hygiene to chemical processing facilities battling corrosion, and from mining operations needing spark resistance to airports requiring lightweight durability, aluminum grating provides a versatile, long-lasting solution. It reduces structural load, minimizes maintenance downtime, enhances worker safety, and ultimately lowers the total cost of ownership.

The Unmatched Benefits of Aluminum Grating in Conveyor Design

Aluminum grating fundamentally transforms conveyor system design and operation. Its most celebrated advantage is its remarkably low weight, typically only about one-third that of equivalent steel grating. This translates directly into significant cost savings throughout the project lifecycle. Lighter grating means reduced load on supporting conveyor structures and building frameworks, potentially allowing for lighter (and cheaper) support steel and foundations. Installation becomes faster, easier, and safer, requiring less heavy lifting equipment and manpower. Transportation costs are also minimized due to the lower weight per square meter.

Beyond weight savings, the corrosion resistance of aluminum grating is a game-changer, especially in environments prone to moisture, chemicals, salt spray, or temperature fluctuations. Aluminum naturally forms a protective oxide layer, shielding it from rust and degradation. This eliminates the need for expensive and recurring protective coatings required by steel, drastically reducing long-term maintenance costs and preventing the unsightly rust staining that plagues steel alternatives. In food processing, chemical plants, wastewater treatment facilities, or coastal applications, this inherent resistance ensures the grating retains its structural integrity and aesthetic appearance for decades, maximizing conveyor uptime and safety.

Furthermore, aluminum grating offers excellent conductivity (both thermal and electrical), is non-sparking – a critical safety feature in explosive or flammable dust environments common around bulk material handling – and is non-magnetic, making it ideal for sensitive electronic or MRI facilities. It’s also 100% recyclable at the end of its exceptionally long service life, aligning with modern sustainability goals. Chengsen’s meticulous production process, governed by rigorous international quality standards at every stage, guarantees that their aluminum grating delivers consistent performance, dimensional accuracy, and load-bearing capacity. Their CAD design expertise ensures seamless integration into complex conveyor layouts, including platforms, walkways, inspection points, and load-bearing sections, providing a cohesive and optimized material handling solution.

Optimizing Flow and Safety with Aluminum Grate Mesh

When the application demands maximum openness for the passage of light, air, sound, liquids, and fine materials, aluminum grate mesh becomes the superior solution for conveyor-integrated platforms, walkways, and safety screens. This type of grating features a pattern of intersecting aluminum bars or strands, creating a high percentage of open area while maintaining structural strength and a secure walking surface.

The primary advantage of aluminum grate mesh in conveyor systems is its ability to prevent the accumulation of debris, liquids, snow, or ice on walking surfaces adjacent to or crossing over the conveyor line. The open mesh design allows these elements to pass through freely, significantly reducing slip and fall hazards for maintenance personnel and operators. This is crucial for maintaining safe access around moving machinery. The openness also facilitates natural drainage and ventilation, preventing puddles that could lead to corrosion on underlying structures (even if the grating itself is immune) and improving overall air quality in enclosed spaces.

Visibility is another key benefit. Aluminum grate mesh allows workers to see through to the conveyor belt or machinery below, enabling easier visual inspection for spills, jams, wear, or potential safety issues without needing to access difficult or dangerous areas directly. This enhances operational monitoring and preventative maintenance routines. The mesh design also contributes to noise reduction in some configurations by breaking up sound waves.

Chengsen’s expertise in producing diverse grating types ensures their aluminum grate mesh offers exceptional slip resistance, a critical factor for OSHA and similar safety regulations globally. The surface can be supplied plain or with enhanced traction features like serrated surfaces or grit coating, tailored to the specific safety requirements of the conveyor environment. The inherent corrosion resistance of aluminum ensures this slip resistance isn't compromised over time by rust or coating failure, providing long-term, reliable safety. Whether used for catwalks over conveyors, safety rail infill panels, or trench covers alongside conveyor lines, aluminum grate mesh enhances safety, visibility, and environmental management within the material handling flow.

The Strength and Durability of Aluminium Bar Grating for Heavy-Duty Conveyors

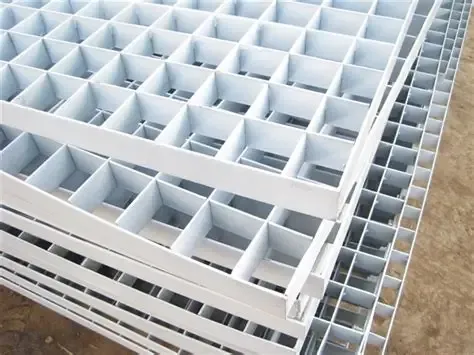

For applications demanding maximum load-bearing capacity and impact resistance within conveyor systems – such as heavy-duty transfer points, truck loading bays, or areas with frequent foot and equipment traffic – aluminium bar grating is the robust solution. This type consists of load-bearing rectangular aluminum bars (bearing bars) securely welded, swaged, or riveted to perpendicular cross bars at precise intervals. The resulting grid structure provides exceptional strength and rigidity.

Aluminium bar grating excels in supporting concentrated loads, whether from foot traffic, pallet jacks, forklifts, or heavy materials potentially falling from the conveyor. The robust bar construction distributes these loads efficiently across the supporting structure. Its high strength-to-weight ratio means it achieves load ratings comparable to much heavier steel grating, maintaining the weight-saving advantages of aluminum while handling significant stress. This makes it ideal for platforms where maintenance vehicles operate near conveyors or at points where heavy items are loaded or unloaded.

Durability is paramount in harsh industrial settings. Aluminium bar grating offers outstanding resistance to impact and abrasion. Its natural corrosion resistance ensures this durability isn't undermined by rust, even when subjected to impacts that might damage protective coatings on steel. This translates to minimal deformation, longer service life, and reduced repair or replacement costs in demanding environments like mining, aggregate processing, foundries, or port logistics.

Chengsen’s extensive experience in producing heavy-duty steel grating directly translates to their mastery of aluminium bar grating. They manufacture to the highest international standards (ANSI/NAAMM MBG531, BS4592), ensuring precise dimensional tolerances, consistent weld integrity, and guaranteed load capacities. Their capabilities include producing a wide range of bar sizes, spacings, and bearing bar depths to meet specific load requirements and deflection limitations for any conveyor support structure or access platform. Whether it’s a standard rectangular panel or a complex special-shaped grating to fit around conveyor machinery, Chengsen’s CAD design team and manufacturing precision ensure a perfect, high-strength fit. Choosing aluminium bar grating from a proven manufacturer like Chengsen means investing in a long-lasting, safe, and reliable foundation for the most demanding sections of your material handling conveyor system.

FAQs About Aluminum Grating for Conveyors

What are the key advantages of aluminum grating?

The primary advantages of aluminum grating are its exceptional strength-to-weight ratio (about 1/3 the weight of steel), outstanding natural corrosion resistance eliminating rust and costly coatings, non-sparking properties for safety in hazardous areas, non-magnetic characteristics, excellent thermal/electrical conductivity, and full recyclability. This combination leads to significant savings: reduced structural support costs, easier and safer installation, minimal lifetime maintenance, enhanced safety compliance, and a lower total cost of ownership despite a potentially higher initial material cost compared to carbon steel. Its longevity in corrosive environments makes it exceptionally cost-effective over decades of service in demanding industrial settings like chemical plants, food processing, and ports.

How does aluminum grate mesh enhance conveyor safety?

Aluminum grate mesh significantly enhances conveyor safety primarily through its high open area. This allows liquids, snow, ice, and fine debris (like spilled granules or dust) to pass through, drastically reducing slip hazards on walkways and platforms adjacent to or crossing conveyors. The open design also improves visibility, allowing workers to monitor conveyor operations and spot potential jams or spills below without direct access. Furthermore, manufacturers can supply aluminum grate mesh with enhanced slip-resistant surfaces (serrated or grit-coated) to meet stringent safety standards like OSHA. Its inherent corrosion resistance ensures this slip resistance remains effective long-term, unlike coated steel that can become slippery if the coating wears or fails. The material's strength ensures a secure walking surface even in high-traffic areas.

Can aluminium bar grating handle heavy conveyor loads?

Absolutely. Aluminium bar grating is specifically engineered for high load-bearing applications within conveyor systems. Constructed from robust rectangular bearing bars securely fastened to cross bars, it efficiently distributes concentrated loads from foot traffic, maintenance vehicles (like pallet jacks), and potential impacts from heavy materials. Its structural design allows it to achieve load ratings comparable to much heavier steel grating, making it ideal for heavy-duty transfer stations, truck loading docks, platforms supporting equipment near conveyors, and areas with frequent forklift access. Manufacturers design and test aluminium bar grating according to rigorous standards (e.g., ANSI/NAAMM MBG531), ensuring it reliably supports specified loads with minimal deflection, providing a safe and durable surface even under significant stress.

Is aluminum grating suitable for corrosive environments?

Yes, aluminum grating is exceptionally well-suited for corrosive environments and is often the best choice for such conditions. Aluminum naturally forms a hard, protective oxide layer when exposed to air, which effectively shields it from rust and corrosion caused by moisture, humidity, salt spray, many chemicals, and atmospheric pollutants. This inherent resistance is far superior to carbon steel and eliminates the need for ongoing maintenance like painting or galvanizing, which can degrade over time. This makes aluminum grating ideal for conveyor applications in food and beverage processing (resistant to cleaning chemicals and food acids), chemical plants, pharmaceutical facilities, wastewater treatment plants, marine ports, coastal installations, and de-icing areas. Its longevity in these harsh settings significantly reduces lifecycle costs.

Why choose aluminum grate mesh for food industry conveyors?

Aluminum grate mesh is an outstanding choice for food industry conveyors due to a unique combination of hygiene, durability, and safety. Its non-porous surface prevents bacteria harborage and is easy to clean and sanitize, meeting strict food safety standards (like FDA, HACCP, GMP). The inherent corrosion resistance withstands constant exposure to water, steam, cleaning detergents, and food acids (like fruit juices or vinegar) without rusting or degrading. The open mesh design allows liquids and small food particles to drain through, keeping walkways drier and cleaner, reducing slip risks and pest attraction. Additionally, aluminum is non-toxic and won't contaminate food products. The non-sparking nature adds another layer of safety in potentially dusty environments. Combined with its strength for supporting personnel and equipment, aluminum grate mesh provides a safe, hygienic, and long-lasting solution for platforms, stairs, and catwalks throughout food processing and packaging facilities.

The choice of grating is far more than a simple flooring decision; it's a critical investment in the efficiency, safety, longevity, and cost-effectiveness of your entire material handling conveyor operation. Aluminum grating, in its various forms – the versatile standard panels, the free-draining aluminum grate mesh, and the robust aluminium bar grating – offers a compelling, modern alternative to traditional steel. Its unparalleled combination of lightweight strength, inherent corrosion resistance, safety features (non-sparking, excellent slip resistance options), and low lifetime maintenance delivers tangible operational and financial benefits.

Partnering with an experienced and reliable manufacturer is crucial to unlocking the full potential of aluminum grating. Shijiazhuang Chengsen Trading Co., Ltd., with its quarter-century of grating expertise, unwavering commitment to international quality standards (YB/T4001.1-2007, BS4592-1-1995, ANSI/NAAMM MBG531-88), and proven export success, stands ready to be your trusted supplier. Their skilled CAD designers ensure perfect grating layouts tailored to your specific conveyor configuration, while their production capabilities guarantee timely delivery of high-performance products. Chengsen’s dedication to "quality first, customer first," evidenced by a remarkable 95% repeat order rate, ensures you receive solutions that enhance safety, reduce downtime, and provide exceptional long-term value.

Don't let your conveyor system be held back by outdated or high-maintenance grating. Embrace the lightweight durability and efficiency of aluminum. Contact Shijiazhuang Chengsen Trading Co., Ltd. today to discuss your specific material handling conveyor grating requirements. Discover how their expertise in aluminum grating, aluminum grate mesh, and aluminium bar grating can optimize your operations, improve safety, and contribute to your bottom line. Let’s build a safer, more efficient, and more profitable future for your facility together.

Latest News

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

-

Ferrotech Grating: Durable Solutions for Modern Industry

NewsNov.17,2025

-

Trusted Aluminum Grating Manufacturers | Durable & Light

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA