Oct . 20, 2025 18:05 Back to list

Welded Wire Mesh Roll—Mallas Electrosoldadas 0.5–4.0mm?

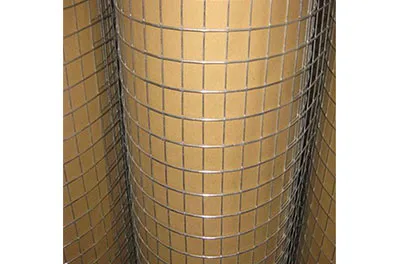

Field Notes on a Workhorse: 0.5-4.0mm Wire And 1/4″-3″ Aperture Mallas Electrosoldadas Welded Wire Mesh Roll

If you spend your days around construction yards, farms, or fabrication shops, you already know the quiet value of welded mesh rolls. They’re not flashy, but they solve problems fast—fencing, plaster support, cages, machine guards. This one, the 0.5-4.0mm Wire And 1/4″-3″ Aperture Mallas Electrosoldadas Welded Wire Mesh Roll, has been popping up on my jobwalks more often lately—mostly because it’s consistent, easy to cut, and shipped in sane lead times.

What’s trending (and why it matters)

Across construction and agri, the shift is toward tighter QA, traceable coatings, and meshes that install faster with fewer snags. In fact, many customers say they’ll pay a bit more for true-tolerance apertures and cleaner welds—because rework costs more than steel. There’s also a subtle push to hot-dip galvanizing or PVC overcoat in coastal jobs to extend service life.

Core specs at a glance

| Wire Diameter | 0.5–4.0 mm |

| Aperture (Opening) | 1/4″–3″ (≈6.35–76.2 mm) |

| Roll Width × Length | 0.5–2.4 m × 10–30 m (common) |

| Material Options | Low-carbon steel (Q195/Q235); Stainless 304/316 (on request) |

| Coatings | Electro-galv (≈15–30 g/m²), Hot-dip (≈50–275 g/m²), or PVC |

| Weld Quality | Resistance-welded cross points; weld shear ≥ ~85% of wire strength (typ.) |

| Tolerance | Aperture/spacing ±2 mm (around), real-world use may vary |

Process, testing, and longevity

Materials are drawn and straightened, then resistance-welded on automated lines for tight, flat rolls. Coatings include pre- or post-weld galvanizing; PVC coating is popular where touch safety or color coding is needed. QC is aligned to ISO 9001—tensile checks (≈350–550 MPa for low-carbon), weld shear tests, zinc thickness per ASTM/EN, and salt-spray (≈72–500 h depending on finish). In service, you’re looking at ≈5–20+ years—site conditions rule, to be honest.

Where it earns its keep

- Construction: plaster/stucco base, light reinforcement, site fencing.

- Agriculture: poultry runs, greenhouse benches, tree guards, feed barriers.

- Industrial: machine guards, partitioning, ventilation screens.

- Residential/DIY: pet enclosures, garden trellises, rodent-proofing.

Real projects (short and sweet)

- Poultry farm, coastal zone: hot-dip mesh cut maintenance visits by ≈40% over 18 months.

- Facade plastering: 1/2″ aperture kept mortar holding uniform; fewer crack callbacks, per contractor’s note.

- Warehouse partition: 2″ opening with 3.0 mm wire met safety guard spec and passed pull tests first time.

Customization and logistics

0.5-4.0mm Wire And 1/4″-3″ Aperture Mallas Electrosoldadas Welded Wire Mesh Roll can be tailored: wire/contact spacing, roll width/length, hot-dip or PVC colors (RAL shades), and edge trims. Origin: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA. Brand: CSTAR. ISO9001. MOQ ≈10 tons. Payment: TT/LC. Capacity ≈10 tons/day. Lead time ≈15–20 days. Packaging: waterproof paper + woven bag, compression rolls, cartons, or as requested.

Why buyers pick it (and when they don’t)

- Pros: flat lay, clean welds, good zinc options, predictable lead times.

- Cons: for heavy structural reinforcement you’d spec dedicated WWR per ASTM A1064 panels.

Customer feedback trends: fewer burrs, fewer on-site cuts per panel run, and—surprisingly—PVC-coated versions get picked for animal comfort and visibility.

Vendor snapshot (quick compare)

| Vendor | Coatings | MOQ | Lead Time | Certs | Customization |

|---|---|---|---|---|---|

| CSTAR (this product) | Electro, Hot-dip, PVC | ≈10 t | ≈15–20 d | ISO9001; test reports | High (aperture, width, color) |

| Vendor A | Electro, Hot-dip | ≈15 t | ≈20–30 d | ISO9001 | Medium |

| Vendor B | Hot-dip, PVC | ≈8 t | ≈25 d | ISO9001 | High |

Standards and references

Latest News

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

-

Ferrotech Grating: Durable Solutions for Modern Industry

NewsNov.17,2025

-

Trusted Aluminum Grating Manufacturers | Durable & Light

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA