Sep . 13, 2025 11:00 Back to list

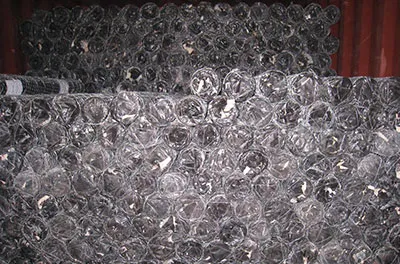

Premium 6×8 Gabion Mesh - Durable Hexagonal Gabion Mesh Boxes

Advanced Engineering Solutions with Gabion Mesh Technology

In the dynamic world of civil engineering and environmental protection, reliable and resilient structural solutions are paramount. Among the most versatile and eco-friendly options, gabion mesh stands out, particularly the robust 6×8 Gabion Mesh. This material is foundational for a wide array of projects, offering exceptional stability, permeability, and longevity. Frequently employed in the form of Gabion Mesh Boxes 1mx1mx1m, these structures provide cost-effective and adaptable solutions for everything from retaining walls to riverbank stabilization. The inherent strength of the Hexagonal Gabion Mesh design ensures structural integrity under diverse environmental pressures, making it an indispensable component for modern infrastructure development. This comprehensive guide delves into the technical aspects, applications, and market significance of these critical engineering components.

Industry Trends and Market Dynamics in Gabion Solutions

The market for gabion solutions is experiencing significant growth, driven by an increased global focus on sustainable infrastructure, natural disaster mitigation, and climate change adaptation. Governments and private entities alike are investing heavily in projects that require robust erosion control, slope stabilization, and hydraulic engineering. Key trends include:

- Environmental Sustainability: Gabions are increasingly favored for their minimal environmental impact, allowing for vegetation growth within and around the structures, promoting biodiversity and natural landscaping.

- Climate Resilience: With rising concerns about extreme weather events, gabions provide flexible and permeable barriers crucial for flood defense, landslide prevention, and coastal protection. The inherent flexibility of 6×8 Gabion Mesh allows it to adapt to ground movement without structural failure, unlike rigid concrete structures.

- Advanced Coatings: The development of enhanced anti-corrosion coatings, such as Galfan (zinc-aluminum alloy) and PVC, extends the service life of gabions significantly, even in harsh environments.

- Modular and Rapid Deployment: The use of pre-fabricated Gabion Mesh Boxes 1mx1mx1m facilitates faster installation, reducing labor costs and project timelines.

- Architectural Integration: Beyond pure engineering, gabions are finding aesthetic applications in landscape architecture, urban design, and sound barriers, blending functionality with visual appeal.

These trends highlight the critical role of durable and adaptable materials like gabion mesh in future infrastructure development, emphasizing both performance and ecological responsibility.

Understanding 6×8 Gabion Mesh: Technical Specifications

The designation "6×8" in 6×8 Gabion Mesh refers to the nominal dimensions of the hexagonal mesh opening, with 6 cm being the approximate short dimension between two parallel wires and 8 cm being the approximate long dimension. This specific mesh size provides an optimal balance between material retention and structural flexibility, making it suitable for a wide range of applications.

Key technical parameters include wire diameter, selvedge wire diameter, lacing wire diameter, and the type of protective coating. Adherence to international standards such as ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses) and EN 10223-3 (Steel wire and wire products for fencing and netting – Hexagonal steel wire netting for civil engineering purposes) is crucial for ensuring product quality and performance.

Table 1: Key Specifications for 6×8 Gabion Mesh

| Parameter | Description | Typical Value/Standard |

|---|---|---|

| Mesh Opening Size (Type) | Double Twisted Hexagonal Mesh | 6cm x 8cm (60mm x 80mm) |

| Mesh Wire Diameter | Wire used for weaving the mesh body | 2.2 mm - 3.0 mm (varies by load) |

| Selvedge Wire Diameter | Heavier wire for reinforcing edges | Typically 0.5 mm - 1.0 mm thicker than mesh wire |

| Lacing Wire Diameter | Wire for assembling gabion units on site | 2.2 mm - 2.4 mm |

| Tensile Strength | Of wire material | 380-550 N/mm² (ASTM A641/A975) |

| Corrosion Protection | Types of coatings applied to the wire | Hot-Dip Galvanized, Galfan (Zn-5%Al-MM), PVC Coated |

| Zinc Coating Mass | Minimum mass of zinc coating per unit area | Min. 245 g/m² (for 2.7mm wire) - ASTM A90 |

| Service Life Expectancy | Estimated durability in typical environments | 30-100 years depending on coating & environment |

The choice of wire diameter and coating type significantly impacts the gabion's structural integrity and longevity, directly influencing its performance in critical civil engineering applications.

Manufacturing Process: From Raw Material to Robust Structure

The production of 6×8 Gabion Mesh is a sophisticated process involving several critical stages to ensure the final product meets stringent quality and performance standards. Precision and quality control are emphasized at every step to guarantee the long-term durability and structural integrity required for demanding B2B applications.

- Wire Rod Selection and Inspection: High-grade, low-carbon steel wire rods, typically meeting ISO 16120 standards, are selected based on their chemical composition and mechanical properties. Each batch undergoes rigorous inspection for impurities and structural defects.

- Wire Drawing: The selected wire rods are drawn through a series of dies to reduce their diameter to the precise gauge required for the mesh wire, selvedge wire, and lacing wire. This process enhances the wire's tensile strength and surface finish.

- Corrosion Protection Coating:

- Hot-Dip Galvanizing: Wires are passed through molten zinc, creating a thick, uniform protective layer that adheres metallurgicaly to the steel, providing excellent corrosion resistance (conforming to ASTM A641 / EN 10244-2).

- Galfan Coating (Zinc-5%Aluminum-Mischmetal Alloy): For superior corrosion protection, especially in aggressive environments, wires are coated with a Zn-Al alloy, offering extended service life compared to standard galvanization.

- PVC Coating: For maximum durability and aesthetic flexibility, a robust PVC layer is extruded over galvanized or Galfan-coated wire. This provides additional protection against abrasion, chemical attack, and UV radiation, often extending lifespan in marine or highly acidic conditions.

- Double-Twist Hexagonal Weaving: Specialized automated machinery meticulously weaves the coated wires into the distinctive double-twist Hexagonal Gabion Mesh pattern. The double-twist mechanism prevents unraveling if a wire is cut, ensuring structural integrity. This precise weaving creates the 6x8 mesh configuration.

- Cutting and Edging: The continuous mesh is then cut into panels according to specified dimensions for Gabion Mesh Boxes 1mx1mx1m or custom sizes. Heavier gauge selvedge wires are machine-crimped or woven into the edges of all mesh panels to provide additional strength and maintain box shape during filling.

- Panel Assembly and Folding: For ease of transport and site assembly, the individual mesh panels (bases, sides, ends, and diaphragms) are precisely cut and pre-assembled or folded flat. Internal diaphragms are included for larger gabion boxes (e.g., those exceeding 1m in length) to prevent bulging and maintain shape.

- Quality Control and Testing: Throughout the process, stringent quality control checks are performed. This includes testing wire tensile strength, elongation, zinc/Galfan coating thickness (e.g., via ASTM A90), PVC coating adhesion, mesh opening dimensions, and panel sizing. Finished products are inspected to ensure compliance with relevant international standards (e.g., ISO 9001, ASTM A975, EN 10223-3).

- Packaging and Dispatch: Completed gabion units are compressed, bundled, and securely packaged to prevent damage during transit, ensuring they arrive on-site in optimal condition, ready for deployment.

This meticulous process guarantees that each 6×8 Gabion Mesh product delivers consistent performance, extended service life, and adherence to the highest engineering standards, offering significant advantages in typical application scenarios requiring corrosion resistance and structural stability.

Technical Advantages of 6×8 Gabion Mesh Systems

The widespread adoption of 6×8 Gabion Mesh in engineering projects is largely attributable to its unique array of technical advantages, making it superior to many conventional construction materials, especially for geotechnical and hydraulic applications.

- Flexibility and Adaptability: The double-twist Hexagonal Gabion Mesh structure allows the gabion units to flex and deform without fracturing. This is critical in areas prone to differential settlement, seismic activity, or dynamic hydraulic pressures, where rigid structures would fail.

- Permeability: Gabion structures are inherently permeable, allowing water to drain freely through the rock fill. This prevents the buildup of hydrostatic pressure behind retaining walls, which is a common cause of failure in solid structures. This also eliminates the need for complex drainage systems.

- Durability and Longevity: With high-quality galvanized, Galfan, or PVC coatings, gabion mesh offers exceptional resistance to corrosion, abrasion, and weathering. The combination of durable wire and inert rock fill ensures a service life of 30 to over 100 years, even in aggressive environments.

- Environmental Integration: Gabions provide natural habitats for flora and fauna, promoting ecological recovery. Their permeable nature allows for groundwater recharge and can support vegetation growth within the rock fill over time, leading to a naturalized and aesthetically pleasing finish.

- Cost-Effectiveness: The use of readily available, locally sourced rock fill significantly reduces material transportation costs. Furthermore, the simple assembly of Gabion Mesh Boxes 1mx1mx1m requires less skilled labor and specialized equipment compared to concrete or masonry construction, leading to overall project savings.

- Energy Dissipation: In river training and erosion control, the rough surface and permeable nature of gabions effectively dissipate the energy of flowing water, reducing scour and preventing erosion.

- High Tensile Strength: The steel wire used in gabion mesh possesses high tensile strength, providing robust structural support for retaining soil and resisting external forces.

These advantages underscore why gabion systems, particularly those built with quality 6×8 Gabion Mesh, are a preferred choice for engineers seeking reliable, sustainable, and economically viable solutions for challenging geotechnical and hydraulic projects.

Application Scenarios & Target Industries

The versatility of 6×8 Gabion Mesh makes it suitable for an extensive range of applications across various industries, primarily focused on civil and environmental engineering. Its ability to combine structural stability with environmental compatibility positions it as a go-to solution for complex projects.

Primary Application Scenarios:

- Retaining Walls: Gabion walls are highly effective for retaining soil on slopes, along highways, or in commercial developments. Their flexibility allows them to accommodate ground movement, a critical advantage over rigid concrete.

- River and Channel Training: Used to control erosion, stabilize riverbanks, prevent scour, and guide water flow in rivers, canals, and drainage channels. The permeability prevents hydrostatic pressure buildup.

- Slope Stabilization: Gabion structures, often in conjunction with geogrids, provide robust support for unstable slopes, preventing landslides and rockfalls in mountainous regions or cut/fill embankments.

- Erosion Control: From coastal protection to agricultural land, gabions protect against soil erosion caused by water or wind, particularly effective in areas with fluctuating water levels.

- Culvert and Bridge Protection: Used to protect the foundations of bridges and culverts from scour and erosion, ensuring the long-term integrity of critical infrastructure.

- Sound Barriers and Architectural Features: Their ability to be filled with various materials (including decorative stone) and their natural aesthetic appeal makes them suitable for sound attenuation walls, boundary fences, and other landscape architectural elements.

Target Industries:

- Civil Engineering: Infrastructure projects including roads, railways, bridges, and urban development.

- Hydraulic Engineering: River and coastal management, dam protection, flood control, and canal lining.

- Environmental & Geotechnical Engineering: Slope stability, erosion control, landslide prevention, and land reclamation.

- Mining Sector: Retaining walls for mining pits, soil stabilization around mining facilities.

- Landscape Architecture: Decorative retaining walls, terracing, garden features, and sound barriers in commercial and public spaces.

The adaptability and robust performance of Gabion Mesh Boxes 1mx1mx1m ensure they remain a cornerstone in modern engineering and environmental management, delivering long-term value across diverse and challenging projects.

Vendor Comparison: Choosing the Right Partner for Gabion Solutions

Selecting a reputable supplier for 6×8 Gabion Mesh and related products is crucial for project success, long-term performance, and cost-effectiveness. Key factors differentiating vendors include product quality, adherence to standards, customization capabilities, and post-sale support.

Table 2: Comparison of Gabion Mesh Material & Coating Types

| Feature | Hot-Dip Galvanized (HDG) | Galfan (Zn-5%Al-MM) Coated | PVC Coated (over HDG/Galfan) |

|---|---|---|---|

| Corrosion Resistance | Good (Standard protection) | Excellent (Superior to HDG) | Outstanding (Best in class) |

| Service Life (Typical) | 30-50 years | 50-75 years | 75-100+ years |

| Abrasion Resistance | Moderate | Good | Excellent (Thick polymer layer) |

| Chemical Resistance | Limited (Acids/alkalis) | Improved | High (Resists many pollutants) |

| UV Stability | Not applicable (metal) | Not applicable (metal) | Excellent (UV stabilized PVC) |

| Cost | Lowest | Medium | Highest |

| Aesthetic Options | Metallic grey | Metallic grey | Various colors (green, grey, black) |

When evaluating vendors for Hexagonal Gabion Mesh, consider their manufacturing quality certifications (e.g., ISO 9001), their ability to provide custom sizes for Gabion Mesh Boxes 1mx1mx1m, and their proven track record. A reliable vendor will offer comprehensive technical support, detailed product data sheets, and transparent lead times, ensuring your project procurement is efficient and risk-free.

Customized Gabion Solutions

While standard 6×8 Gabion Mesh and Gabion Mesh Boxes 1mx1mx1m fulfill many project requirements, complex engineering challenges often necessitate bespoke solutions. Reputable manufacturers offer extensive customization options to precisely match project-specific needs, ensuring optimal performance and structural integrity.

Customization Parameters Include:

- Dimensions: Tailored gabion box lengths, widths, and heights to accommodate specific site constraints or design requirements, beyond the standard 1x1x1m.

- Wire Gauges: Adjustment of mesh wire, selvedge wire, and lacing wire diameters to meet specific load-bearing requirements or expected stress levels, enhancing durability for high-impact applications.

- Coating Types: Selection from hot-dip galvanized, Galfan, or various colors of PVC coating to match environmental conditions (e.g., marine, acidic soils) or aesthetic preferences.

- Mesh Configurations: While 6x8 is standard, other mesh sizes (e.g., 8x10 for larger rock fill) can be provided depending on the hydraulic or geotechnical demands.

- Diaphragm Placement: Strategic placement and number of internal diaphragms to prevent bulging and maintain the structural shape of unusually long or tall gabion units.

- Fabrication for Specific Structures: Design and fabrication of specialized gabion elements for culvert aprons, weir structures, or complex terracing systems.

Partnerships with experienced manufacturers offering engineering support ensure that custom solutions are not only precisely fabricated but also optimized for structural performance and longevity. This collaborative approach minimizes risks and enhances the overall efficiency of complex projects, providing significant value to B2B clients.

Real-World Application Case Studies

The practical utility and robust performance of 6×8 Gabion Mesh are best illustrated through real-world applications, showcasing its versatility and effectiveness in addressing complex engineering challenges.

Case Study 1: Highway Embankment Stabilization

Challenge: A major highway expansion project required the stabilization of a steep embankment prone to erosion and minor landslides, located in a region with significant rainfall. Traditional concrete retaining walls were deemed too rigid for the unstable soil conditions and ecologically disruptive.

Solution: Engineers opted for a tiered gabion retaining wall system using PVC-coated 6×8 Gabion Mesh units. The inherent flexibility of the gabions accommodated ground settlement, while the permeable nature allowed for effective drainage of rainwater, preventing hydrostatic pressure buildup. The PVC coating provided enhanced corrosion resistance against acidic runoff.

Outcome: The gabion system successfully stabilized the embankment, preventing further erosion and ensuring highway safety. Over time, vegetation integrated with the gabion fill, enhancing the aesthetic appeal and ecological value of the roadside.

Case Study 2: Riverbank Protection and Flood Mitigation

Challenge: A critical section of a major river, flowing through an agricultural area, experienced severe bank erosion during seasonal floods, threatening farmland and local infrastructure. Traditional concrete lining was rejected due to its ecological impact and rigidity.

Solution: A comprehensive river training scheme was implemented using large Gabion Mesh Boxes 1mx1mx1m filled with local river stones. These boxes were strategically placed along the banks to create a robust, yet flexible, revetment. The use of Galfan-coated Hexagonal Gabion Mesh ensured long-term durability in the aquatic environment.

Outcome: The gabion revetment effectively stabilized the riverbanks, resisting erosion even during peak flood events. The permeable nature maintained the natural water flow dynamics, and the rough surface dissipated water energy, further protecting downstream areas. The project proved both environmentally sensitive and highly effective.

Case Study 3: Commercial Landscape Retaining Feature

Challenge: A new commercial complex required aesthetically pleasing yet functional retaining features for terraced gardens and parking areas on a sloping site. The client desired a modern, natural look that also offered robust soil retention.

Solution: Custom-sized 6×8 Gabion Mesh units were used to construct terraced retaining walls. These units were filled with a combination of local angular stone and decorative river pebbles to create varied textures and colors, aligning with the architectural vision. Some gabion walls were designed with integrated planter boxes.

Outcome: The gabion walls provided excellent soil retention and drainage, contributing to stable and vibrant terraced gardens. Their distinctive appearance became a key design element, showcasing how gabions can seamlessly blend engineering function with high-end landscape aesthetics.

Ensuring Trust: Certifications, Warranty & Support

For B2B procurement, trust is built upon verifiable quality, robust support, and transparent commitments. As a leading provider of 6×8 Gabion Mesh and related products, we prioritize these aspects to ensure client confidence and project success.

Authoritative Certifications & Quality Assurance:

- ISO 9001 Certified Manufacturing: Our production facilities adhere to the highest international standards for quality management systems, ensuring consistency and reliability in every product.

- Compliance with Global Standards: All gabion mesh products, including Hexagonal Gabion Mesh and Gabion Mesh Boxes 1mx1mx1m, meet or exceed relevant industry specifications such as ASTM A975, EN 10223-3, and other applicable regional standards.

- Rigorous Testing Protocols: Our materials undergo continuous testing for tensile strength, coating thickness, and mesh dimensions, verified by internal QA/QC teams and independent third-party laboratories.

- Decades of Industry Experience: With extensive years of service in the mesh manufacturing industry, we have cultivated deep expertise and a proven track record of delivering successful projects to a diverse portfolio of clients globally.

Lead Time & Fulfillment Details:

We understand the critical nature of project timelines. Our advanced manufacturing capabilities and streamlined logistics ensure efficient order processing and timely delivery. Standard orders typically have a lead time of 2-4 weeks, depending on volume and customization. For urgent or large-scale projects, we offer expedited production and shipping solutions. Clients receive detailed fulfillment schedules and real-time tracking updates from order confirmation to final delivery.

Warranty Commitments:

We stand behind the quality of our products with robust warranty provisions. All our gabion mesh products are covered by a comprehensive warranty against manufacturing defects and premature coating failure, typically ranging from 5 to 10 years, contingent on the specific coating type (e.g., HDG, Galfan, PVC) and application environment. Detailed warranty certificates are provided with each order, outlining terms and conditions.

Dedicated Customer Support & Technical Assistance:

Our commitment extends beyond product delivery. A dedicated team of technical experts and customer service professionals is available to provide comprehensive support, including:

- Pre-Sales Consultation: Assisting with material selection, specification matching, and custom solution design.

- Technical Support: Guidance on installation best practices, rock fill selection, and structural considerations.

- After-Sales Service: Prompt response to any inquiries, technical issues, or warranty claims.

- Documentation: Providing detailed product manuals, test reports, and compliance certificates.

This holistic approach ensures that our clients receive not just a product, but a complete, reliable, and supported solution for their engineering needs.

Frequently Asked Questions (FAQ) about Gabion Mesh

- Q1: What is the primary difference between a 6x8 and an 8x10 Gabion Mesh?

- A1: The numbers refer to the mesh opening size in centimeters (short way x long way). A 6×8 Gabion Mesh has smaller openings (60x80mm) compared to an 8x10 mesh (80x100mm). The 6x8 mesh is generally used for smaller rock fill and where greater structural integrity with finer retention is required, while 8x10 can accommodate larger rock fill and is often used for larger structures or revetments.

- Q2: How long can I expect a gabion structure to last?

- A2: The service life of a gabion structure depends heavily on the wire coating and environmental conditions. Hot-dip galvanized gabions typically last 30-50 years. Galfan-coated gabions can last 50-75 years. PVC-coated gabions, especially when applied over galvanized or Galfan wire, can provide a service life exceeding 75-100 years, making them ideal for aggressive or marine environments.

- Q3: Can Gabion Mesh Boxes 1mx1mx1m be used in marine environments?

- A3: Yes, but specific coatings are required. For marine or brackish water environments, PVC-coated gabions (over a Galfan or heavy galvanization base) are highly recommended. The PVC layer provides an additional barrier against salt spray, tidal action, and chemical corrosion, significantly extending the lifespan of the Hexagonal Gabion Mesh.

- Q4: What kind of rock fill is best for gabions?

- A4: Ideal rock fill should be hard, durable, non-frost susceptible, and angular to sub-angular in shape to allow for good interlocking and minimize voids. The stone size should be larger than the mesh opening to prevent egress. For 6×8 Gabion Mesh, rock sizes typically range from 100mm to 200mm.

- Q5: Are gabions environmentally friendly?

- A5: Absolutely. Gabions are considered one of the most environmentally friendly civil engineering solutions. They are permeable, allowing water flow and natural drainage, preventing hydrostatic pressure. They can also be vegetated, promoting ecological integration and providing habitats for local flora and fauna. The use of local rock fill reduces carbon footprint associated with material transport.

Conclusion

The 6×8 Gabion Mesh stands as a testament to engineering ingenuity, offering a blend of flexibility, durability, and environmental compatibility that few other materials can match. From critical infrastructure projects requiring robust erosion control to aesthetically driven landscape designs, the versatility of Gabion Mesh Boxes 1mx1mx1m and Hexagonal Gabion Mesh solutions continues to make them a preferred choice for B2B decision-makers and engineers worldwide. By understanding its technical specifications, manufacturing precision, and diverse application potential, clients can harness the full benefits of this exceptional material to deliver sustainable, resilient, and cost-effective projects.

References

- ASTM A975/A975M-11, Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating). ASTM International.

- EN 10223-3:2013, Steel wire and wire products for fencing and netting - Hexagonal steel wire netting for civil engineering purposes. European Committee for Standardization.

- Boutwell, G.P. (2009). Gabion Wall Design. Geosynthetic Institute. Retrieved from geosynthetic-institute.org.

- Maccaferri Gabions Technical Manual. (2018). Maccaferri International. Retrieved from maccaferri.com.

- ISO 9001:2015, Quality management systems — Requirements. International Organization for Standardization.

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA