Sep . 11, 2025 10:40 Back to list

Open Mesh Safety Grating: Expanded Metal Steel Grating - Lowes Quality

Industry Trends and Market Dynamics for Open Mesh Safety Grating

The industrial sector's continuous evolution, particularly in construction, infrastructure development, and manufacturing, has significantly amplified the demand for robust and reliable safety solutions. A critical component in this landscape is Open Mesh Safety Grating Expanded Metal Lowes Steel Grating. This product is at the forefront of ensuring worker safety and operational efficiency across diverse environments. Current market trends indicate a strong shift towards materials offering superior strength-to-weight ratios, enhanced corrosion resistance, and simplified installation, all while adhering to stringent international safety standards.

Emerging trends also highlight a growing preference for sustainable manufacturing practices and products with extended service life, reducing the need for frequent replacements and minimizing environmental impact. Digitalization in procurement and supply chain management is another key driver, streamlining the process of sourcing high-quality grating solutions. The demand for customized solutions that fit precise architectural and engineering requirements, rather than off-the-shelf products, is also on a steady rise, reflecting the complexity of modern industrial projects. Companies that can provide detailed technical support, rapid prototyping, and scalable production will dominate this competitive market.

Manufacturing Process of Open Mesh Safety Grating

The production of Open Mesh Safety Grating Expanded Metal Lowes Steel Grating is a precise, multi-stage process designed to ensure structural integrity, durability, and compliance with industry standards such as ISO 9001 and ANSI A126.1-2017 for walking working surfaces. The typical manufacturing flow involves several critical steps:

1. Material Selection and Preparation:

High-grade steel coils, primarily low carbon steel (e.g., ASTM A36, Q235, or stainless steel grades like 304, 316), are selected based on the application's required corrosion resistance, load-bearing capacity, and environmental conditions. These coils undergo initial quality checks for material composition and surface integrity.

2. Expanding Process (Cold Forming):

The prepared steel sheets are fed into an expanding machine. This machine utilizes specialized dies to simultaneously slit and stretch the metal. Unlike weaving or welding, this process creates a continuous, integral piece of mesh without any joints or welds. This results in a much stronger product with a higher strength-to-weight ratio. The expansion angle and die configuration determine the LWD (Long Way of Design) and SWD (Short Way of Design) of the mesh openings, defining the grating's pattern and open area percentage.

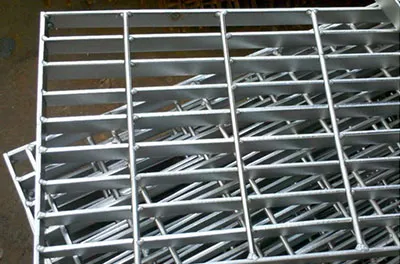

3. Flattening (Optional):

For applications requiring a smoother surface or reduced thickness, the expanded metal can be cold-rolled through heavy-duty rollers. This flattens the strands and bonds, resulting in a flat expanded metal grating (FEM) which offers a more uniform surface, albeit with a slight reduction in rigidity compared to standard expanded metal (SEM).

4. Cutting and Shaping:

The expanded metal sheets are then cut to the specified dimensions using CNC plasma cutters, laser cutters, or shear machines. This ensures high precision and minimizes material waste. Custom shapes and panel sizes are easily accommodated at this stage.

5. Surface Treatment:

Surface treatments are crucial for enhancing the product's service life and resistance to environmental factors. Common treatments include:

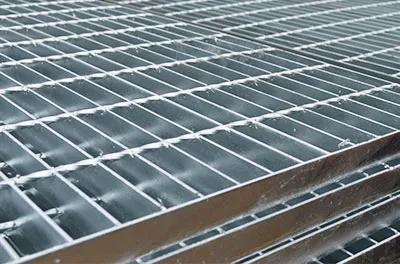

- Hot-Dip Galvanizing: Applying a protective zinc coating by immersing the steel in a bath of molten zinc. This offers superior corrosion resistance, especially in harsh outdoor or marine environments. Average coating thickness typically ranges from 60-100 microns, adhering to ASTM A123/A123M standards.

- Electro-Galvanizing: A thinner, more aesthetic zinc coating applied via an electrolytic process, suitable for less corrosive environments.

- Powder Coating: Applying a dry powder that is then cured under heat to create a hard finish, offering various colors and enhanced durability.

- Painting/Priming: Basic protection and aesthetic finish.

6. Quality Control and Testing:

Throughout the process, rigorous quality control checks are performed. Final inspections include dimensional accuracy, surface finish, coating adherence, and load-bearing tests. Manufacturers often conduct slip-resistance tests (e.g., per ASTM F1679 or UL 410) to confirm safety performance. Typical service life for galvanized steel grating can exceed 20-30 years in moderate environments, and even longer for stainless steel or well-maintained systems.

This meticulous manufacturing process ensures that the grating products meet the demanding requirements of target industries such as petrochemical, metallurgy, mining, water supply & drainage, power generation, and transportation, offering advantages in corrosion resistance, energy saving through improved ventilation, and structural integrity.

Technical Specifications and Parameters

Understanding the technical specifications of Open Mesh Safety Grating Expanded Metal Lowes Steel Grating is crucial for proper selection and installation. These parameters dictate the product's suitability for specific load requirements, environmental conditions, and safety standards.

Key Technical Parameters:

- Material: Low Carbon Steel (Q235, A36), Stainless Steel (304, 316), Aluminum.

- Surface Treatment: Hot-Dipped Galvanized, Electro-Galvanized, Powder Coated, Painted.

- Mesh Type: Standard Expanded Metal (SEM) or Flattened Expanded Metal (FEM).

- Opening Size (LWD x SWD): Ranging from typically 12x25mm to 50x100mm, influencing open area and strength.

- Strand Thickness: 1.5mm to 6.0mm, directly impacting load capacity.

- Strand Width (Bond): 1.0mm to 8.0mm, contributing to the panel's overall rigidity.

- Panel Size: Customizable, standard sheets often 1220x2440mm, 1500x3000mm, or roll forms.

- Open Area: Typically 60-80%, allowing for light, air, and liquid passage while maintaining structural integrity.

- Load Capacity: Varies significantly based on material, mesh size, strand dimensions, and unsupported span. Engineered for specific point and uniform loads.

- Slip Resistance: Expanded metal's raised surface provides inherent slip resistance, often meeting OSHA requirements (29 CFR 1910.22).

Typical Product Specification Table:

| Parameter | Value/Range | Unit/Description |

|---|---|---|

| Material | Q235 Mild Steel | Per ASTM A36 equivalent |

| LWD x SWD | 45 x 15 (Typical) | mm (Long Way of Design x Short Way of Design) |

| Strand Thickness | 3.0 | mm |

| Strand Width | 3.0 | mm |

| Panel Weight | 18.5 | kg/m² (approx.) |

| Finish | Hot-Dip Galvanized | Per ASTM A123/A123M |

| Allowable Load (Uniform) | 3.5 kPa (for 1m span) | Engineering calculation required for specific spans |

These specifications allow engineers and project managers to precisely match the grating to structural load requirements and environmental conditions, ensuring optimal performance and safety compliance. Specialized load tables, often provided by manufacturers, detail permissible loads for various spans and grating types, critical for structural integrity in industrial applications.

Key Technical Advantages

The inherent design and material properties of Open Mesh Safety Grating Expanded Metal Lowes Steel Grating offer a multitude of technical advantages that make it a superior choice for industrial safety and operational platforms.

- Exceptional Strength-to-Weight Ratio: The expansion process creates a continuous, single piece of metal without welds, resulting in a robust structure that can bear significant loads while remaining relatively lightweight. This simplifies installation, reduces structural support requirements, and lowers overall project costs.

- Superior Slip Resistance: The raised, angular surface of standard expanded metal inherently provides excellent traction, significantly reducing the risk of slips and falls, especially in wet, oily, or icy conditions. Flattened expanded metal also offers good grip compared to smooth surfaces.

- Excellent Air, Light, and Liquid Permeability: The open mesh design allows for unimpeded passage of light, air, and liquids, which is crucial for ventilation, natural lighting, and drainage on platforms, walkways, and stair treads. This also prevents the accumulation of debris, enhancing safety and reducing maintenance. In processing plants, this can contribute to energy savings by reducing the need for artificial lighting and improving air circulation for cooling.

- Corrosion Resistance: When subjected to appropriate surface treatments like hot-dip galvanizing, the steel grating gains formidable resistance against rust and chemical corrosion. This extends its service life dramatically in aggressive industrial environments such as chemical plants, offshore platforms, and wastewater treatment facilities, minimizing lifecycle costs.

- Durability and Longevity: Manufactured from high-quality steel and processed under strict quality controls, these gratings are designed to withstand heavy foot traffic, dynamic loads, and harsh weather conditions, ensuring long-term performance with minimal degradation.

- Security and Anti-Theft Properties: The continuous, integral structure of expanded metal makes it difficult to cut or dismantle, offering a degree of security against unauthorized access or theft, particularly when used for fencing or machinery guards.

- Cost-Effectiveness: Despite its high performance, expanded metal grating is often more cost-effective than other grating types, such as bar grating, due to efficient material utilization and simplified manufacturing processes. Its long lifespan and low maintenance further contribute to overall cost savings.

Application Scenarios and Target Industries

The versatility and robust properties of Open Mesh Safety Grating Expanded Metal Lowes Steel Grating make it indispensable across a wide array of industrial and commercial applications. Its design, promoting safety and functionality, serves diverse sectors globally.

Target Industries:

- Petrochemical and Oil & Gas: Used for elevated walkways, offshore drilling platforms, stair treads, and equipment maintenance access in refineries and production facilities due to its superior corrosion resistance and non-slip surface, critical for preventing accidents in hazardous environments.

- Metallurgy and Mining: Ideal for screening, conveying, and safety platforms in smelters, foundries, and mining operations where durability and resistance to heavy impact and abrasion are paramount.

- Water Supply & Drainage: Employed in water treatment plants, pumping stations, and drainage systems for trench covers, filter supports, and maintenance platforms, benefiting from its excellent drainage capabilities and resistance to moisture.

- Power Generation: Utilized in power plants (thermal, nuclear, hydro) for boiler platforms, catwalks, turbine halls, and electrical enclosures, where fire safety, ventilation, and reliable access are crucial.

- Transportation: Found in railway platforms, bridge walkways, ship decks, and pedestrian overpasses. Its open design prevents snow and ice accumulation, and its high load capacity supports heavy traffic.

- Industrial Manufacturing: Used for machine guards, shelving, security partitions, mezzanines, and cleanroom floors, providing safety, ventilation, and compliance with industrial standards.

- Architectural and Design: Increasingly used for aesthetic purposes in building facades, sunscreens, and decorative fencing, offering a blend of security, light diffusion, and modern appeal.

Typical Application Scenarios:

- Walkways and Platforms: Providing safe, anti-slip surfaces for personnel access in elevated areas, mezzanines, and equipment pathways.

- Stair Treads and Landings: Ensuring secure footing on stairs, even in challenging industrial conditions.

- Trench and Pit Covers: Protecting open trenches while allowing for drainage and inspection.

- Machine Guards and Safety Barriers: Creating protective enclosures around machinery to prevent accidents without obstructing visibility or ventilation.

- Security Fencing and Gates: Offering robust, difficult-to-climb barriers for perimeter security.

- Building Facades and Sunscreens: Enhancing architectural aesthetics while providing shade and air circulation.

The adaptability of these gratings to severe operating conditions, coupled with their structural benefits, confirms their status as a critical engineered solution across heavy industries.

Customized Solutions and Design Flexibility

In complex industrial environments, off-the-shelf solutions often fall short of meeting specific functional, structural, or aesthetic requirements. This is where the ability to provide customized Open Mesh Safety Grating Expanded Metal Lowes Steel Grating becomes a significant advantage for B2B clients. Manufacturers specializing in these products offer extensive design flexibility to address unique project demands.

- Tailored Dimensions: Grating panels can be cut, shaped, and fabricated to precise lengths, widths, and complex geometries, ensuring a perfect fit for any structure, from custom platforms to irregular trench covers. Advanced CNC cutting technologies facilitate intricate designs with high accuracy.

- Material and Gauge Customization: Depending on the required load capacity, corrosion resistance, and budget, clients can specify different materials (e.g., specific grades of carbon steel, stainless steel 304/316, aluminum) and varying strand thickness and width. This directly impacts the grating's strength, weight, and lifespan.

- Mesh Configuration: The LWD and SWD of the mesh openings can be varied to achieve specific open area percentages, influencing light/air permeability, drainage capacity, and the size of objects that can fall through. This is crucial for environments requiring fine filtration or stringent safety against falling tools.

- Specialized Finishes: Beyond standard galvanization, custom powder coatings in specific RAL colors can be applied for branding, aesthetic integration, or enhanced resistance to particular chemicals or UV exposure. Electropolishing for stainless steel can provide an ultra-smooth, highly corrosion-resistant finish for hygienic environments.

- Integrated Fabrication: Manufacturers can provide grating panels with pre-welded support bars, banding, toe plates, and attachment clips, reducing on-site fabrication and installation time and costs. Stair treads can be supplied with pre-drilled holes and nosing.

- Engineering Support: Reputable vendors offer expert engineering consultation to help clients define the optimal grating specifications, conduct load calculations, and ensure compliance with relevant industry codes and safety standards (e.g., IBC, OSHA). This collaborative approach ensures that the final product not only meets but often exceeds expectations.

This level of customization empowers businesses to implement grating solutions that are perfectly aligned with their operational needs, ensuring maximum safety, efficiency, and return on investment.

Vendor Comparison and Selection Criteria

Choosing the right supplier for Open Mesh Safety Grating Expanded Metal Lowes Steel Grating is critical for project success, ensuring product quality, timely delivery, and competitive pricing. A thorough vendor comparison should extend beyond mere cost to encompass several key criteria.

Key Vendor Selection Criteria:

- Product Quality and Certifications: Verify if the vendor adheres to international quality standards (e.g., ISO 9001). Request material test certificates (MTCs), galvanizing reports, and compliance with relevant industry standards (e.g., ASTM, ANSI, OSHA).

- Manufacturing Capabilities: Assess the vendor's ability to handle custom orders, production volume, and lead times. Advanced machinery (e.g., CNC, automated galvanizing lines) indicates higher efficiency and precision.

- Technical Expertise and Support: A reputable vendor should offer engineering support for design, load calculations, and material selection, demonstrating deep product knowledge and problem-solving capabilities.

- Experience and Track Record: Look for vendors with a proven history in supplying similar B2B projects. Customer testimonials, case studies, and a list of key partner clients can provide insights into their reliability and performance.

- Lead Time and Logistics: Evaluate the vendor's ability to meet project deadlines and their logistics capabilities for efficient and safe delivery to your site.

- Pricing and Value Proposition: While cost is a factor, consider the overall value, including product lifespan, warranty, and after-sales support. A lower upfront cost may lead to higher lifecycle costs if quality is compromised.

- Customization Options: The ability to provide tailored solutions for specific project needs, as discussed previously, is a significant differentiator.

- Environmental & Safety Compliance: Ensure the vendor’s manufacturing processes comply with environmental regulations and safety standards.

Vendor Comparison Table Example:

| Feature/Criterion | Vendor A | Vendor B | Vendor C (Example) |

|---|---|---|---|

| ISO 9001 Certified | Yes | Yes | No |

| Hot-Dip Galvanizing (ASTM A123) | In-house facility | Outsourced | Limited capacity |

| Custom Fabrication Capability | High | Moderate | Limited |

| Average Lead Time (Large Order) | 3-4 Weeks | 5-6 Weeks | 8+ Weeks |

| Engineering Support | Dedicated team | Basic support | None |

| Warranty Offered | 5 Years | 2 Years | None stated |

This structured comparison aids in selecting a partner that aligns with project requirements and long-term business goals, ensuring a reliable supply of high-quality grating solutions.

Real-World Application Case Studies

The practical application of Open Mesh Safety Grating Expanded Metal Lowes Steel Grating demonstrates its efficacy and reliability in demanding industrial settings. These case studies highlight real-world benefits and problem-solving capabilities.

Case Study 1: Offshore Oil Platform Walkways

Challenge: An offshore oil platform required a durable, highly corrosion-resistant, and anti-slip walking surface for its extensive network of catwalks and service platforms. The existing bar grating suffered from severe corrosion due to saline conditions and frequent maintenance issues.

Solution: Custom-fabricated hot-dip galvanized expanded metal grating (LWD 60mm x SWD 25mm, strand thickness 4.5mm) was chosen. The integral structure provided superior strength, while the hot-dip galvanization offered enhanced protection against the harsh marine environment. The raised surface significantly improved slip resistance, crucial for worker safety in wet and oily conditions.

Outcome: After 5 years of installation, the expanded metal grating showed minimal signs of corrosion or wear. Worker incident rates related to slips and falls decreased by 30%, and maintenance costs associated with grating replacement were reduced by 40% annually, providing a substantial return on investment.

Case Study 2: Wastewater Treatment Plant Filter Media Support

Challenge: A municipal wastewater treatment plant needed a robust yet open support structure for filter media in its aeration tanks. The material had to withstand continuous exposure to aggressive chemicals and high humidity, while allowing efficient water flow.

Solution: Stainless steel 316 expanded metal grating with a relatively large open area (LWD 75mm x SWD 30mm, strand thickness 3.0mm) was designed and fabricated. Stainless steel 316 offers superior resistance to chloride-induced corrosion, making it ideal for the highly corrosive environment of a wastewater treatment plant. The large open area facilitated optimal water flow and aeration.

Outcome: The stainless steel expanded metal grating provided exceptional long-term performance, resisting chemical degradation and structural fatigue. The plant reported improved filtration efficiency and reduced downtime for support structure maintenance, leading to operational cost savings and enhanced treatment capacity.

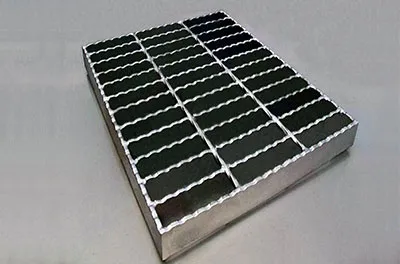

Case Study 3: Industrial Machine Guarding

Challenge: A large automotive manufacturing facility required durable, transparent, and secure machine guarding to protect personnel from moving parts while allowing for clear visibility and ventilation of machinery.

Solution: Flattened expanded metal (FEM) with a smaller mesh size (LWD 20mm x SWD 10mm, strand thickness 2.0mm) was powder coated in safety yellow and installed as modular machine guards. The smaller mesh provided effective containment of small debris and protection against limb access, while the flattened surface offered a smoother, more aesthetic finish. The open design maintained good ventilation for the machinery and visibility for operators.

Outcome: The facility achieved full compliance with machine guarding safety regulations. Incidents related to contact with moving machinery were eliminated, and the enhanced visibility improved operational efficiency. The modular design also allowed for easy access for maintenance when needed.

Frequently Asked Questions (FAQ)

- Q1: What is the primary advantage of expanded metal grating over welded bar grating?

- A1: Expanded metal grating is formed from a single sheet of metal through slitting and stretching, meaning there are no welds or joints that can fail under stress or corrosive conditions. This results in a higher strength-to-weight ratio and greater durability compared to welded bar grating, which can suffer from weld fatigue or corrosion at weld points.

- Q2: How is slip resistance achieved with expanded metal grating?

- A2: Standard expanded metal grating inherently offers excellent slip resistance due to its raised, angular strands. This unique texture provides multiple gripping points, significantly reducing the risk of slips, especially in wet, oily, or icy conditions, complying with safety standards like OSHA's requirements for walking surfaces.

- Q3: Can expanded metal grating be customized for specific load requirements?

- A3: Yes, absolutely. Customization is a key strength. Load capacity can be tailored by varying the material type (e.g., carbon steel, stainless steel), strand thickness, strand width, and the dimensions of the mesh opening (LWD x SWD). Our engineering team can perform specific load calculations to ensure the grating meets your project's precise requirements and safety factors.

- Q4: What surface treatments are available to enhance corrosion resistance?

- A4: The most common and effective treatment for steel grating is hot-dip galvanizing, which provides a robust zinc coating per ASTM A123/A123M for superior corrosion protection. Other options include electro-galvanizing for lighter protection, powder coating for aesthetic and additional corrosion resistance, and for stainless steel, options like electropolishing or passivating are available.

- Q5: What is the expected service life of expanded metal grating?

- A5: The service life varies based on the material, surface treatment, and environmental conditions. Hot-dip galvanized carbon steel grating typically lasts 20-30 years in moderate industrial environments. Stainless steel grating offers even longer lifespans, often exceeding 50 years, particularly in highly corrosive or hygienic applications, with proper maintenance.

Lead Time, Warranty, and Customer Support

Understanding the logistical and post-purchase support aspects is crucial for B2B procurement. We are committed to providing transparent information regarding lead times, comprehensive warranty coverage, and reliable customer support for our Open Mesh Safety Grating Expanded Metal Lowes Steel Grating products.

Lead Time and Fulfillment:

Our standard lead time for typical expanded metal grating orders ranges from 3 to 5 weeks from order confirmation, depending on the volume, customization requirements, and current production schedule. For urgent or large-scale projects, we offer expedited production options. We maintain robust inventory levels for common materials and sizes to facilitate quicker turnaround for standard products. All orders are meticulously packaged to prevent damage during transit and are shipped via trusted logistics partners to ensure timely and secure delivery to your specified location.

Warranty Commitments:

We stand by the quality and durability of our expanded metal grating products. All grating supplied comes with a comprehensive 5-year limited warranty against manufacturing defects and material failures under normal use and recommended installation. This warranty covers defects in materials and workmanship, ensuring your investment is protected. Specific warranty details, including terms and conditions, are provided with each quotation and can be reviewed prior to purchase.

Dedicated Customer Support:

Our commitment to our clients extends beyond delivery. We provide dedicated customer support throughout the entire project lifecycle, from initial inquiry to post-installation. Our experienced technical support team is available to assist with product selection, technical specifications, installation guidance, and any after-sales queries. We offer multi-channel support including phone, email, and dedicated account managers to ensure prompt and effective communication. Our goal is to forge long-term partnerships built on trust, reliability, and unparalleled service.

Conclusion

The utility and robust nature of expanded metal grating position it as a critical component in modern industrial and construction endeavors. Its technical advantages, including superior strength-to-weight ratio, exceptional slip resistance, and adaptability to harsh environments, make it an indispensable safety and functional element across a broad spectrum of industries. From petrochemical facilities requiring extreme corrosion resistance to architectural projects demanding aesthetic versatility, expanded metal grating offers a compelling solution. The ability to customize dimensions, materials, and finishes ensures that specific project requirements are not only met but optimized for performance and longevity. By selecting a vendor with strong manufacturing capabilities, comprehensive technical support, and transparent after-sales commitments, B2B clients can ensure the successful implementation of high-quality expanded metal grating solutions, contributing to safer, more efficient, and cost-effective operations.

References

- American Society for Testing and Materials (ASTM) International. (Various standards, e.g., ASTM A123/A123M for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products, ASTM A36/A36M for Carbon Structural Steel).

- Occupational Safety and Health Administration (OSHA). (29 CFR 1910.22 Walking-working surfaces).

- International Organization for Standardization (ISO). (ISO 9001 Quality Management Systems – Requirements).

- American National Standards Institute (ANSI). (ANSI A126.1-2017 for Walking Working Surfaces).

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA